Determine Your Machine's Load Capacity: A Practical Guide

Learn how to determine the load capacity of your machine with step-by-step methods, safety checks, and practical tips for engineers, technicians, and DIY enthusiasts.

To determine the load capacity of your machine, start with the nameplate data, user manual, and manufacturer specifications. Cross-check rated payload against operating conditions, and verify limits for bearings, frame, and drive components. If possible, perform a controlled test with calibrated weights, observing for strain, overheating, or unusual vibration. Document results for audits and maintenance.

What load capacity means and why it matters

Load capacity is the maximum usable load a machine, structure, or component can handle safely under specified conditions. It defines the boundary between normal operation and failure risk. In engineering terms, you’ll see terms like rated load, safe working load, or maximum operating load. The Load Capacity perspective emphasizes that load ratings account for factors such as material strength, geometry, wear, temperature, lubrication, and duty cycle. Understanding load capacity helps prevent equipment damage, unexpected downtime, and safety incidents. For engineers, technicians, and DIYers, the goal is to work within rated limits and confirm that your actual use-case matches the rating. Always treat load specifications as design limits, not targets; exceeding them increases risk and can invalidate warranties.

According to Load Capacity, a clear grasp of load capacity reduces surprises during commissioning, maintenance, and upgrades. The right rating supports reliable performance and safer, longer equipment life. This article walks you through locating official ratings, interpreting documentation, validating with safe tests, and keeping an auditable record for audits and warranties.

How to locate official specifications and ratings

Start with the machine’s nameplate, which usually lists the numeric rating, load class, and operating conditions. Next, consult the user manual or datasheet for more precise definitions (e.g., peak vs. nominal ratings) and any safety margins. If you cannot access documentation, visit the manufacturer's website or contact technical support. When you gather data, record the exact unit of measure, environmental factors (temperature, humidity), and the version of the rating (serial number/date). Cross-check that the rating applies to your scenario (static vs dynamic loads, single-point vs distributed loads). This step helps you build a reliable baseline before any testing or field use.

The Load Capacity team recommends compiling data from multiple sources to resolve inconsistencies and to maintain a defensible trail for future reference.

Interpreting nameplates, manuals, and data sheets

Nameplates may show symbols like SWL, WLL, or rated load along with a duty cycle or operating range. Manuals translate these into practical guidance about safe use, maintenance intervals, and warning thresholds. Data sheets often include a table of limits, test conditions, and recommended safety factors. Learn to recognize common pitfalls: ambiguous terms, mixed units (lb vs kg), or ratings that do not account for attached accessories. Align the data with your intended configuration to avoid misinterpretation. If terms are unclear, consult the manufacturer or a qualified engineer to interpret the documentation accurately.

For critical equipment, ensure you’re reading the correct version of the spec (e.g., updated after maintenance or retrofits).

Safe methods to verify load capacity with practical tests

Where permissible, perform a controlled load test using calibrated weights or load cells. Begin well below the rated capacity and incrementally increase while monitoring signs of strain, unusual noise, or overheating. Use a stable, level testing surface and ensure all safety guards are in place. Record the exact load, observed behavior, ambient conditions, and the test date. If your test suggests a mismatch with the official rating, do not operate at the expected load; instead document the discrepancy and pursue official verification from the manufacturer. Keep PPE on, and stop immediately if any abnormal behavior occurs.

Documenting results and maintaining your rating

Create a results log that captures the rating source, test date, test method, and any margins or safety factors. Include photos of measurements and any calibration certificates. Schedule periodic reviews, especially after maintenance, repairs, or wear. If changes in ambient conditions or usage patterns occur, re-test to confirm safety margins. The goal is to maintain an auditable trail that demonstrates compliance with safety requirements and supports future maintenance planning. Regular documentation also helps inform upgrades or process changes without interrupting operations.

Common pitfalls and safety considerations

Don’t rely on visual estimates or rough judgments for loads. Always respect units and ensure the load matches the rating’s intended definition (static vs dynamic). Never exceed rated limits, and avoid attaching fixtures that alter the effective load path. Be mindful that wear, temperature, and lubrication impact real-world capacity; plan re-tests after significant maintenance or environmental changes. Ensure you have proper PPE and a clear, unobstructed testing area to minimize risk to people and equipment.

When to consult a professional

If ratings are unclear, if you observe signs of unusual wear, or if your application involves critical safety constraints, contact a qualified engineer or the manufacturer for formal load testing and site-specific guidance. A professional can certify the setup, provide an updated rating if required, and help you align with relevant safety standards.

Tools & Materials

- Official machine nameplate(Record the exact rating and operating conditions)

- Manufacturer's manual or datasheet(Obtain definitions of 'rated load' and safety margins)

- Calibrated weights or load testing equipment(Used for controlled, incremental loading within safe range)

- Scale, load cell, or dynamometer (optional)(Use for direct load measurement if available)

- Personal protective equipment (PPE)(Safety glasses, gloves, sturdy footwear)

- Stable testing surface and secure mounting fixtures(Ensures accurate readings and safety during tests)

Steps

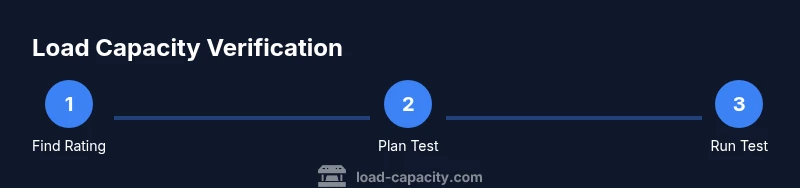

Estimated time: 45-90 minutes

- 1

Gather official ratings

Locate the nameplate, manual, and datasheet. Record the exact rating and the conditions under which it applies. Photograph all sources for your records and note the unit of measure.

Tip: Take close-up photos of the nameplate and keep digital copies of the datasheet. - 2

Verify operating conditions

Confirm whether the rating refers to static or dynamic loads, single-point or distributed loads, and any duty cycle limitations. Align these conditions with your intended use.

Tip: Double-check that your environment matches the rating's tested conditions. - 3

Plan a safe test approach

Define a stepwise loading plan that stays well within the rated limit. Identify stopping criteria (excessive heat, vibration, or noise). Ensure the testing area is clear of bystanders and obstacles.

Tip: Have a second person monitor gauges and signs during loading. - 4

Apply load incrementally

Add calibrated weights gradually, pausing at each increment to observe for distress signals or anomalies. Note the load at which any warning signs occur.

Tip: Record loads precisely with timestamps and ambient conditions. - 5

Monitor and document results

Use a load cell or scale to capture measurements, and compare with rated values. Document deviations, sensor readings, and any protective actions taken.

Tip: Keep all calibration certificates up to date for traceability. - 6

Conclude with a formal comparison

If tests align with ratings, you’ve validated the capacity. If not, document the discrepancy and seek official verification or an updated rating.

Tip: Store the final report with maintenance records for future audits.

Quick Answers

What is the difference between load capacity, payload, and bearing capacity?

Load capacity is the maximum safe load a machine can carry under specified conditions. Payload is the actual load carried in a given use case, which must stay within the load capacity. Bearing capacity relates to the support structure’s ability to carry the load without failing.

Load capacity is the maximum safe load; payload is the actual load used, which must stay within that limit. Bearing capacity concerns the support structure's strength.

Where can I find official load capacity ratings?

Check the machine's nameplate and the manufacturer’s manual or datasheet. If needed, contact technical support or the manufacturer’s website for the latest ratings and safety margins.

Look on the nameplate and in the manual; contact the manufacturer if you can't locate the rating.

Can load capacity change with wear or temperature?

Yes. Wear, temperature, lubrication, and mounting conditions can reduce the actual capacity. Regular checks and re-testing help ensure ongoing safety.

Wear and temperature can reduce capacity, so you should re-check periodically.

What should I do if my test shows a mismatch with the rating?

Document the discrepancy with timestamps and methods, then seek official verification from the manufacturer or a qualified engineer before proceeding.

If your test disagrees with the rating, document it thoroughly and consult the manufacturer.

How often should load capacity be re-tested?

Re-test after maintenance, component replacements, or changes in load usage. Establish a periodic schedule based on risk and usage.

Re-test after changes or maintenance; set a periodic schedule based on risk.

Is there a difference between static and dynamic load capacity?

Yes. Static capacity refers to loads at rest, while dynamic capacity covers moving or accelerating loads. Ensure the rating you use matches your application.

Static loads are at rest; dynamic loads include movement and acceleration. Use the appropriate rating.

Can I use a non-certified test procedure to verify capacity?

Non-certified tests may provide useful insights but should not replace official ratings. They can help flag potential issues but require professional validation.

Non-certified tests can help identify issues but aren’t a substitute for official ratings.

Watch Video

Top Takeaways

- Identify the official rating from nameplate and manual.

- Test within safe margins and document results.

- Compare test results to ratings and maintain records.

- Re-test after maintenance or significant wear.