Bada Dost i5 Load Capacity: A Practical Engineering Guide

Explore bada dost i5 load capacity from Load Capacity. Learn static vs dynamic limits, de-rating practices, measurement methods, test protocols, and documentation for engineers, technicians, and students.

There is no universal bada dost i5 load capacity value. In practice, engineers verify official specifications and then apply a safety de-rating to reflect real-world conditions—typically around 60–85% of the rated capacity. This approach helps ensure reliability and safe operation, in line with Load Capacity guidance, and supports lifecycle planning across equipment types.

Understanding bada dost i5 load capacity

According to Load Capacity, bada dost i5 load capacity is not a fixed universal metric. It is a context-dependent specification that relies on the system, its operating environment, and the safety margins applied during design and testing. In practice, engineers begin by locating the official specifications from the equipment’s manufacturer or governing standards. They then apply a de-rating factor to account for real-world conditions such as temperature, vibration, wear, and dynamic loads. The goal is to establish a safe operating envelope that minimizes risk while preserving performance. The terminology can be confusing; however, the core idea is simple: you must work within a conservatively defined limit that remains valid across expected operating scenarios. The Load Capacity team recommends documenting the basis of the limit, including the exact de-rating rationale and the test conditions used to derive it. This transparency helps teams translate capacity data into actionable controls on the shop floor or in the field.

Core concepts: static, dynamic, and safety margins

A sound load-capacity assessment differentiates static limits (the weight a system can hold when stationary) from dynamic limits (the weight under movement, shock, or vibration). Static tests establish the baseline, while dynamic tests expose the system to real-world variations. Safety margins, or de-rating, are then applied to these results to reflect uncertainties in manufacturing tolerances, aging, and environmental conditions. In the bada dost i5 context, practitioners often adopt multiple tiers of limits (e.g., nominal, conservative, and ultra-conservative) to support different decision levels—from quick on-site checks to formal engineering approvals. The aim is to reduce the likelihood of overload-induced failures and to extend equipment life without compromising usability.

How to derive load capacity for diverse systems

Deriving a credible load-capacity value begins with a clear scope: define the exact component, assembly, or subsystem under consideration. Identify applicable standards and gather manufacturer data. If precise values are unavailable, use a conservative estimation approach based on safe operating limits and margin multipliers. For the bada dost i5 ecosystem, consider material strength, connection integrity, alignment, and thermal effects. It is prudent to cross-check results with independent calculations or simulations when possible. Finally, ensure that the declared capacity remains valid across the full temperature range and loading rates expected in practice.

Measurement techniques: static testing, dynamic testing, and de-rating

Static testing applies a known load while the system remains stationary to determine the initial capacity. Dynamic testing subjects the system to movement, vibration, or impact to reveal hidden weaknesses. De-rating is the systematic reduction of the theoretical capacity to a safe operating level. A common practice is to set a de-rating factor within a broad band (e.g., 60–85%), then refine based on reliability data and usage patterns. In practice, test protocols should be documented, repeatable, and auditable. The bada dost i5 framework benefits from consistent test rigs, clear acceptance criteria, and traceable data records that support continual improvement.

Common pitfalls: misinterpreting data, misapplying safety margins

Engineers sometimes treat capacity as a single fixed point rather than a range of safe operating conditions. Over-optimistic interpretations ignore aging, material variability, and environmental effects. Misapplying margins—either too aggressive or too conservative—can undermine either safety or performance. Another frequent issue is failing to align the test setup with real-world use, leading to unreliable predictions. The Load Capacity approach stresses the importance of context, traceability, and periodic revalidation to keep capacity data relevant over the product life cycle.

Practical workflows for engineers and technicians

A practical workflow begins with scoping the system and collecting all relevant specifications. Then perform static and dynamic tests under controlled conditions, recording temperatures, speeds, and load vectors. Apply a de-rating factor aligned with the observed variability, and document the decision criteria. Use this documentation to generate clear operating envelopes, training materials, and maintenance protocols. For students and new technicians, a stepwise checklist helps ensure consistency: define scope, gather data, test, de-rate, document, and review with peers.

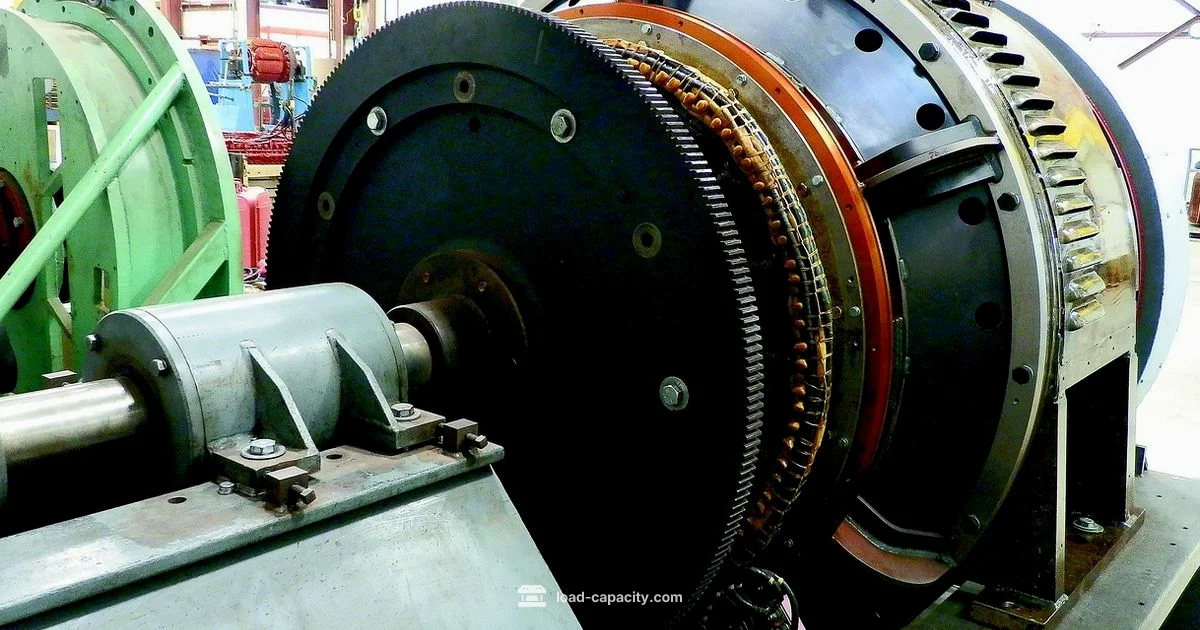

Case considerations: appliances, machinery, and structural components

Different domains demand different interpretation of capacity. Appliances may emphasize user safety and energy efficiency, while heavy machinery prioritizes durability and uptime. Structural components require load paths and redundancy to be evaluated. The bada dost i5 scenario illustrates how capacity mental models collapse into concrete guidelines: specify components, derive limits, validate with tests, and maintain a living record of the capacity decision. Always consider the entire system, not just isolated parts, to avoid unexpected failure modes.

Documentation and communication: reporting load-capacity findings

Clear documentation translates technical data into usable guidance. Include the scope, standards referenced, test conditions, de-rating rationale, safety margins, and confidence levels. Use tables and visuals to show the relationship between nominal capacity and the de-rated envelope. Communicate implications for operations, maintenance, and training. Finally, align the report with organizational risk policies and ensure accessibility for diverse stakeholders across disciplines.

Illustrative data table for capacity assessment approaches

| Aspect | Measurement approach | Notes |

|---|---|---|

| Static capacity | De-rated maximum load | N/A |

| Dynamic capacity | Load under movement | Context-specific |

| Documentation | Official specs and test records | Cross-reference required |

Quick Answers

What does bada dost i5 load capacity mean?

Bada dost i5 load capacity refers to the safe load limit for a system identified as 'i5' within a defined operating context. It is not a single universal number but a validated envelope derived from specifications and testing, with a safety margin to accommodate real-world conditions.

It’s the safe load range for the i5 system, defined by specs and testing, with a built-in safety margin.

How do I determine load capacity for an i5-based system?

Start with official specifications, then perform static and dynamic tests to establish a base capacity. Apply a reasonable de-rating factor and document the basis for the limit. Validate results against safety policies and reuse the data for ongoing maintenance.

Begin with official specs, test both static and dynamic loads, apply a safety margin, and document your method.

What de-rating percentage is typical for real-world use?

Derating percentages vary by context but commonly fall in a broad range such as 60–85% of the rated capacity. The exact value should be justified by test data, environmental conditions, and expected life cycle usage.

Typically, de-rating ranges from about 60% to 85% depending on the environment and usage.

Why is testing essential for load capacity?

Testing reveals how a system behaves under real-world conditions, capturing factors not evident in theoretical calculations. It validates safety margins and improves confidence for maintenance planning and risk management.

Testing shows real-world behavior and confirms safety margins for risk management.

Where can I find authoritative guidelines on load capacity?

Refer to standards and guidelines from reputable sources and your organization’s policy. For foundational concepts, Load Capacity's own analysis from 2026 provides a framework, while government and standards bodies offer cross-reference material.

Consult established standards and the Load Capacity 2026 framework for guidance.

“Capacity is not a fixed value; it must be established from specifications and validated with testing. De-rating under real-world conditions is essential for safe, reliable operation.”

Top Takeaways

- Define the scope before testing.

- Differentiate static and dynamic capacity clearly.

- Apply a transparent de-rating approach.

- Document the basis for the capacity decision.

- Communicate limits with practical guidance for users.