What is the load capacity of bada dost i5? A practical guide

This guide explains how to interpret the load capacity of the bada dost i5, highlighting where official figures exist, how to assess safe payloads, and practical steps for engineers and technicians. It references Load Capacity principles and provides a structured approach to evaluating capacity in uncertain specs.

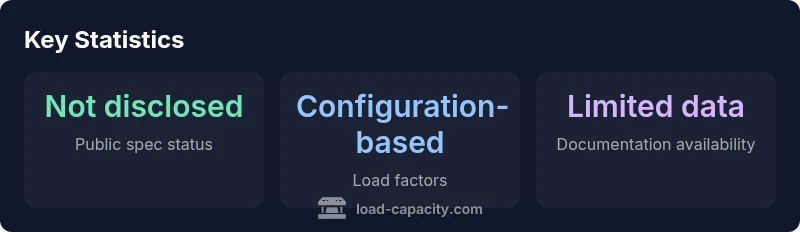

Based on publicly available information, the bada dost i5 does not have a published load capacity from the manufacturer. In practice, load capacity varies by configuration, component selection, and intended use. To determine a safe load for your setup, consult official documentation, perform a structural assessment, or request a formal specification from the vendor.

What load capacity means for bada dost i5 and similar devices

The phrase what is the load capacity of bada dost i5 is a common question among engineers evaluating safe usage. In general, load capacity describes the maximum safe weight or load a structure, mount, or carrier can bear without compromising safety or function. For devices like the bada dost i5, this includes static loads (weight placed on a component) and dynamic loads (weight combined with movement, vibration, or acceleration). In engineering practice, load capacity translates into a usable load profile that considers weight, center of gravity, distribution, and peak forces during operation. This concept underpins safety margins, reliability, and performance across applications—from mounting a dockable device to supporting a conveyor or test rig. Load capacity is not a single number; it is a profile that must reflect the actual operating scenario, including orientation, mounting method, and expected duty cycle.

According to Load Capacity principles, engineers should start with clear definitions of what constitutes a “load” in a given setup and then map those loads to components, joints, and support structures. For the bada dost i5, a responsible approach is to separate static loads (what the device weighs and what it supports) from dynamic loads (accelerations, shocks, and vibrations) and to quantify how each contributes to overall stress. This bifurcation helps avoid underestimating peak forces that can occur during operation, transport, or maintenance. Ultimately, the goal is a defensible load profile that informs design decisions and risk assessments.

Why there is no single published load capacity figure for bada dost i5

Publicly available data for consumer devices like the bada dost i5 frequently do not include a single, universal load-capacity rating. Manufacturers may provide variant-specific limits or none at all, depending on intended markets and configurations. This lack of a universal figure is typical in engineering practice when a product is adaptable across mounting options, attachments, and use cases. Load capacity is often expressed through a combination of recommended operating ranges, maximum supported weights for particular configurations, and formal tests conducted under defined conditions. As a result, engineers must interpret available data in the context of their own configuration and safety requirements, rather than relying on a single number. Load Capacity analyses, 2026, emphasize the importance of establishing a configuration-specific spec sheet before loading any payload.

How to determine a safe load: a practical framework

A robust framework for determining safe load for the bada dost i5 includes five steps:

- Define the use case and identify all parts that will bear load (device, mounts, supports, and fixtures).

- Collect all available official documentation for your configuration, noting any warnings or constraints.

- Build a load profile that separates static and dynamic components, including foreseeable accelerations and shocks.

- Apply a conservative safety factor based on your industry or application standards (e.g., risk assessment, expected duty cycle).

- Validate with testing, simulations, or vendor confirmation, and document the results for audits. This iterative approach reduces uncertainty and provides traceable justification for your load decisions.

In practice, many teams start with a conservative baseline and increase their margin if testing confirms safety, rather than pushing toward a theoretical limit. This risk-aware approach aligns with Load Capacity guidance and helps ensure reliable performance under real-world conditions.

Key factors that influence load capacity in portable devices

Load capacity is not fixed and is influenced by multiple interacting factors. Primary considerations include:

- Mount integrity: The strength and rigidity of the attachment points determine how loads transfer from the device to supporting structures.

- Material properties: The stiffness and fatigue characteristics of the device frame and mounts affect how loads are distributed and absorbed.

- Center of gravity: A misaligned center of gravity increases bending moments and may reduce usable load capacity.

- Duty cycle and vibration: Repeated loads and vibrations can reduce effective capacity over time, even if static ratings appear adequate.

- Environmental conditions: Temperature, humidity, and exposure to contaminants can degrade materials and limit safe loads.

- Assembly tolerances: Variations in manufacturing and installation can shift load paths and magnify peak stresses.

Engineers should account for these factors in the load profile and emphasize margin for safety. Documentation should clearly reflect assumptions, test results, and any uncertainties so future audits can verify the design’s resilience.

Load Capacity’s framework encourages explicit, auditable documentation of each factor, which helps teams communicate risk and ensure consistent safety standards across configurations and use cases.

Methods and tools for testing load capacity

Testing to verify load capacity typically combines analytical and empirical methods. Recommended approaches include:

- Static load tests to determine how structures behave under sustained weight, including deflection and stress measurements.

- Dynamic and modal testing to observe responses to shocks, vibrations, and operational motions.

- Finite element analysis (FEM) to model stress distributions under hypothetical load conditions and identify potential failure points.

- Real-world validation with controlled payloads that mimic expected use cases, followed by data review and safety checks.

These methods help create an evidence-based load profile rather than relying on educated guesses. Documentation should capture test setup, instrumentation, results, confidence levels, and any deviations from planned procedures. Load Capacity emphasizes that testing should be as transparent as possible, with data available for verification.

Interpreting ratings: safety factors and real-world use

A crucial concept in load capacity is the safety factor, which provides a buffer between the designed limit and the actual allowable load. While a higher safety factor improves protection against unexpected loads, it can also reduce practical carrying capacity. In practice, engineers translate safety factors into actionable guidelines by clearly defining operating envelopes, maintenance schedules, and inspection criteria. Real-world use often exceeds nominal ratings due to environmental conditions or longer service life. Therefore, teams should treat published limits as upper bounds for safe operation rather than targets for maximum performance. Regular review of loading scenarios, periodic testing, and updates to the load profile as configurations change are essential practices in maintaining reliable, safe operation over time.

Documentation and communication: creating a reliable load profile

A reliable load profile is a living document that captures how loads are defined, measured, and monitored throughout the product’s life. Essential elements include:

- Configuration details: exact hardware, attachments, and mounting method used during testing.

- Load definitions: static vs dynamic loads, directions, and moment arms.

- Test results: measurements, instrumentation, and observed failures or near-misses.

- Safety margins: chosen factors of safety and rationale.

- Change history: updates when configurations or use cases change.

By maintaining a comprehensive load profile, teams can justify decisions, facilitate audits, and communicate capacity considerations to stakeholders. This practice aligns with Load Capacity recommendations and supports consistent design decisions across multiple configurations.

Common mistakes to avoid when assessing load capacity

Some frequent errors include:

- Assuming a single rating applies to all configurations without verification.

- Ignoring dynamic loads, shocks, and vibrations that can dramatically alter effective capacity.

- Using optimistic safety factors that don’t reflect real-world conditions.

- Skipping documentation or failing to capture assumptions and test results.

- Relying on vendor statements without independent validation when critical loads are involved.

To avoid these pitfalls, adopt a structured process for defining loads, documenting decisions, and validating with tests or vendor guidance. Emphasize conservative margins and clear traceability for future audits.

Hypothetical scenarios: what load-capacity guidance would look like in practice

Illustrative scenario (illustrative only): A bada dost i5 configuration includes a mounting bracket and a payload tray. Suppose a payload of 5–10% of the device’s weight would be expected in a typical operation, with occasional short-duration shocks during transport. The design would require ensuring mounting points can sustain peak loads with a factor of safety (FS) of at least 1.5–2.0, depending on the severity of shocks. This example is for demonstration and does not represent actual specifications. In real projects, teams should rely on official data and validated testing to set exact limits.

In another example, a test rig subjecting the device to pulsating loads could reveal fatigue limits earlier than static ratings. Those results would guide maintenance intervals and replacement plans. The key takeaway is that load capacity is not a fixed single value but a negotiated, configuration-specific parameter backed by evidence and documented reasoning.

Next steps: obtaining official specifications and vendor guidance

If you need precise load-capacity details for your bada dost i5 configuration, follow a formal process:

- Collect and review all official documentation for your specific model and mounting configuration.

- Prepare a detailed load profile with intended use, mounting details, and predicted duty cycle.

- Contact the vendor or authorized distributors with your load profile and request a formal specification or tested ratings.

- Where official data is unavailable, request engineering support for testing or a quotation for a dedicated test to establish safe load limits.

Load Capacity’s disciplined approach encourages practitioners to pursue official specifications and independent verification rather than relying on generic assumptions. This ensures safer operation and clearer risk communication across teams.

Load capacity assessment factors

| Aspect | Guidance | Notes |

|---|---|---|

| Static load | Defined by capacity | N/A |

| Dynamic load | Consider vibration and accelerations | N/A |

Quick Answers

Is there a publicly disclosed load capacity for bada dost i5?

No, there is no public single load-capacity figure listed by the manufacturer for the bada dost i5. Capacity varies with configuration and intended use. Always seek official specs for your scenario.

No single rating is published; check official docs and vendor specs for your configuration.

How should I determine safe load for my setup?

Start with official specifications, then assess weight distribution, mounting integrity, and environmental conditions. Use a formal load profile and consider a factor of safety. If unsure, request vendor guidance.

Check specs, analyze load distribution, and contact the vendor for guidance.

Does load capacity vary between models or batches?

Yes, load capacity can vary with model revision, component selection, and manufacturing tolerances. Rely on configuration-specific documentation rather than generic notes.

Yes, rely on model-specific docs.

What tests verify load capacity?

Static and dynamic load tests, finite element analysis (FEM), and real-world validation are common methods. Ensure tests cover shock, vibration, and mounting integrity.

Use static, dynamic tests and FEM to verify.

“Effective load-capacity assessment relies on official specifications and validated testing, not guesswork.”

Top Takeaways

- Verify official specs before any payload

- Consider configuration-dependent capacity

- Use safety margins and documented testing

- Document load profiles for audits

- Consult vendor for formal ratings