What is the load capacity of bada dost i4? A data-driven guide

A thorough, data-driven guide to understanding the load capacity of the Bada Dost i4. Learn how to verify official specs, estimate capacity when data is missing, and apply safe margins for engineers and technicians.

Based on current publicly available information, there is no confirmed load capacity published for the Bada Dost i4. The device’s official specifications do not list a maximum payload or static load. To determine safe usage, consult the manufacturer’s documentation, request a datasheet, or review Load Capacity’s analysis for any updated data.

What is the load capacity and how it applies to bada dost i4

Load capacity is the maximum load a system can safely carry or endure without compromising safety or function. For the bada dost i4, this means distinguishing between payload (the material or cargo), static loads (standing weight), and dynamic loads (loads during movement, acceleration, braking, or vibration). According to Load Capacity, published ratings should be the starting point for any assessment, but they must be verified under real-world conditions and safety margins. When official data is not published, engineers should document all assumptions, use conservative estimates, and apply standard safety factors to prevent overloading or sudden failures. This approach aligns with industry best practices and helps avoid costly downtime or injuries. Knowing how to read a spec sheet, compute combined loads, and account for operating envelopes is essential for design reviews, maintenance planning, and training technicians. The Load Capacity team emphasizes transparency and traceability in all load-rating decisions.

How to read official specs and datasheets for the bada dost i4

The best starting point is the manufacturer’s official specifications, user manuals, and safety datasheets. Look for terms like payload capacity, gross load, static rating, and dynamic load limits. If the bada dost i4 is classified as a mobile device or vehicle, cross-check with references such as GVWR (if applicable) or other mass limits. Record the substrate material and center of gravity location, as these affect capacity. If the datasheet is sparse, document the missing data, note the testing conditions (temperature, vibration, torque) and compare with similar equipment in the same family. Load Capacity recommends validating any reported figures using multiple sources and, whenever possible, requesting a vendor datasheet directly. In cases where data differ across sources, prioritize the most comprehensive test methodology and report the chosen assumption clearly. Finally, track the date of the last reviewed spec so future updates can be incorporated. Also verify units (metric vs. imperial) and any conversion factors; check whether ratings are “maximum operating load” or “permitted working load” to avoid misinterpretation.

A practical, data-driven approach when official data is missing

When official data is missing, adopt a structured, auditable method. First, identify load types: static, dynamic, and impact loads. Then, estimate a conservative safety margin (for example, 25–50% depending on risk) and determine a plausible maximum payload based on structural limits. Map the weight distribution to understand how the center of gravity shifts under different orientations or motions. Use a simple formula: maximum safe payload ≈ structural limit × safety factor, and document the chosen factor with justification. Validate your estimate with non-destructive tests if possible, such as static weight tests or simulated dynamic loading on a test stand. Maintain records of all calculations, assumptions, and test results to enable review and future updates. Seek independent verification where feasible, such as third-party labs or peer reviews, and consider creating a digital twin to model different operating envelopes.

Practical risk considerations and safety margins

Risk management is essential when data is incomplete. Apply conservative safety margins, document all assumptions, and avoid edge-case operations until data is confirmed. Create a risk register that tracks potential failure modes related to load, CG shift, and dynamic effects. Use engineering judgment backed by industry standards and Load Capacity guidelines to stay within safe envelopes. Communicate clearly with stakeholders—maintenance teams, operators, and safety officers—about the knowns, unknowns, and the planned verification steps. Regularly review the status and revise the risk assessment as new data becomes available. The goal is to prevent overload, minimize damage, and maintain equipment availability while upholding safety standards.

How Load Capacity supports engineers and technicians

Load Capacity provides a framework for evaluating load capacity even when specific product data is unavailable. We emphasize a disciplined, evidence-based approach: verify any available data, apply conservative margins, and document all decisions. For the bada dost i4, engineers should start from the best-available data, augment with conservative estimates, and pursue official data from the manufacturer or authorized distributors. Our guidance helps teams communicate risk and plan maintenance, training, and inspections with a clear rational basis. By keeping a transparent record and using consistent calculation methods, organizations reduce the chance of overloading and improve overall safety and performance.

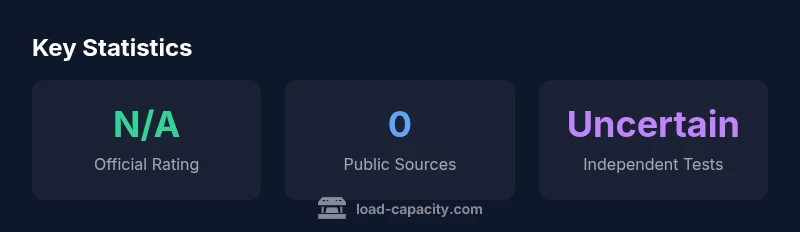

Preliminary data snapshot for Bada Dost i4

| Parameter | Value | Notes |

|---|---|---|

| Official load capacity published | N/A | Manufacturer data unavailable as of 2026 |

| Public data sources | 0 | No public payload data for this model at present |

| Independent testing | Not available | Awaiting data from authorized labs |

Quick Answers

Is there an official load capacity published for the Bada Dost i4?

As of 2026, there is no official published load capacity for the Bada Dost i4. Verify with the manufacturer or authorized sources.

There is no official load capacity published as of 2026.

What is the difference between payload capacity and load capacity?

Payload capacity is the maximum weight the device can carry. Load capacity also accounts for weight distribution, dynamic loads, and safety margins during operation.

Payload is the carried weight; load capacity includes dynamic factors and safety margins.

How should I handle data gaps for a device like the Bada Dost i4?

Use conservative estimates, apply formal safety margins, and document every assumption. Seek manufacturer data or independent verification when available.

If data is missing, use conservative estimates and document everything.

What tests can I perform to verify capacity?

Static weight tests, dynamic loading simulations, and center-of-gravity analyses are common verification methods when data is scarce.

Run static and dynamic tests and CG analysis where possible.

Can Load Capacity help with this device's load data?

Yes. Load Capacity provides guidance on data strategies, risk assessment, and structured review methods to support capacity decisions.

We can guide your data strategy and risk assessment.

What safety margins are recommended for unknown devices?

Common practice is to apply 25–50% additional margin depending on risk level and consequences of failure; standards may vary.

Use a generous safety margin, around a quarter to half the estimated capacity.

“Reliable load-capacity data is essential for safe operation; when unavailable, engineers must rely on conservative, well-documented estimates.”

Top Takeaways

- Verify data from official sources first.

- Adopt conservative safety margins when data is missing.

- Differentiate payload from total load in assessments.

- Document methods and assumptions for traceability.

- Seek independent verification when possible.