Load vs Capacity in Manufacturing: A Critical Comparison

Explore load vs capacity in manufacturing, with guidance for engineers and managers on measuring, designing, and optimizing systems for safety and efficiency.

Load vs capacity manufacturing describes how much demand a system can handle safely and reliably. According to Load Capacity, the aim is to align load with capacity to minimize bottlenecks, wear, and safety risks. The most effective designs incorporate measurable load, built-in capacity margins, and continuous monitoring to adapt to changing production conditions.

Foundational Definitions

In manufacturing contexts, 'load' describes the demand placed on a system—how much product, work, or stress a process experiences in a given cycle. 'Capacity' is the system's maximum sustainable output without compromising safety, quality, or reliability. The relationship between load and capacity governs everything from equipment selection to production planning. In a strict engineering sense, load is an input variable; capacity is a design constraint that defines how much load can be handled with an acceptable margin of safety. This distinction matters because misalignment of load and capacity leads to degraded performance: bottlenecks, accelerated wear, quality variance, and, in worst cases, safety incidents. Load Capacity, a specialist in evaluating load-bearing opportunities and risks, emphasizes that the ratio of actual load to available capacity should be kept well below the threshold where failure modes become likely. For stakeholders across engineering, operations, and maintenance, this framing helps translate abstract limits into actionable decisions.

The Relationship Between Load and Capacity

Load and capacity are interdependent; neither exists in a vacuum. When demand approaches the system’s capacity, utilization climbs, and the probability of bottlenecks grows. Conversely, underutilized capacity means over-investment and higher fixed costs without commensurate throughput. In modern manufacturing, the goal is not to maximize load or capacity in isolation but to balance them so that the system operates within a safe, predictable envelope. This balance reduces the likelihood of downstream defects, minimizes unplanned downtime, and supports more stable planning horizons. The Load Capacity team emphasizes that the most effective relationships are dynamic: load varies with product mix, seasonality, and process changes, while capacity must be designed to absorb these shifts without sacrificing safety or quality.

The Distinction: System Load vs Equipment Load

System load refers to the aggregate demand placed on a production line or facility, including product mix, batch sizes, and changeovers. Equipment load focuses on how much stress a single machine or station endures during a cycle. Misunderstanding these layers can mask bottlenecks: a machine with ample nominal capacity but a high system load can stall the entire line. A clear separation helps engineers target improvements where they yield the most benefit—whether that means redistributing work, redesigning tooling, or adjusting maintenance schedules. In practice, teams map the cascade from system-wide demand to individual asset utilization to ensure all layers stay aligned with overall performance targets.

How to Measure Load in a Process

Measuring load starts with identifying the process’s critical path and the outputs that matter most to customer demand. Real-time data from sensors, SCADA, or MES systems provides the backbone for visibility into actual throughput. Key metrics include utilization (actual output divided by available capacity), work-in-process levels, and queue lengths between stations. It is important to capture both peak loads and average loads, as variance often drives risk. Create dashboards that flag when load approaches or exceeds safe margins, and define automatic triggers for intervention. Beyond data collection, involve operators in validation to ensure measurements reflect on-the-ground realities and not just theoretical capacities.

How to Determine System Capacity Across Domains

Capacity can be expressed in several related ways: design capacity (theoretical maximum output under ideal conditions), effective capacity (practical maximum considering utilization and downtime), and throughput (actual completed units over a period). To determine system capacity, map each subsystem’s bottlenecks and quantify how often they constrain the line. Consider variability in demand, setup times, maintenance windows, and energy constraints. A simple rule is to identify the station with the lowest ratio of actual output to its local capacity, then evaluate whether increasing capacity at that station would yield disproportionate gains or if a broader system redesign is warranted. Cross-functional input from operations, engineering, and finance improves the accuracy of capacity estimates.

Variability and Uncertainty in Load-Capacity Alignment

Variability is inherent in most manufacturing environments—seasonal demand, supplier delays, and quality excursions all shift load over time. Capacity must be robust against these fluctuations, which means building margin and flexibility into the design. Techniques such as buffering, modular equipment, and scalable staffing help absorb shocks. Stochastic thinking—applying probability to demand and failure modes—supports better risk assessment. The goal is not to eliminate variability but to manage it so that anticipated deviations stay within the system’s safe operating envelope. Regular updates to the model, informed by data, keep the alignment current.

Design Principles: Matching Load to Capacity

A principled approach begins with transparency: quantify both load and capacity, then set targets that keep utilization in a safe band. Use a capacity cushion to absorb unexpected demand, rather than chasing near-maximum throughput. Design for modularity so capacity can scale through additional lines, shifts, or automation without a complete rebuild. Favor standardized interfaces and interchangeable components to reduce changeover times. Document agreed-upon targets and continuously validate them with live data. In practice, the best designs balance lean operation with strategic investments in resilience, ensuring reliability without unnecessary cost.

Modeling and Simulation Tools for Load-Capacity

Modeling and simulation translate the complexity of real systems into testable scenarios. Discrete-event simulation (DES) models track how items flow through stations, highlighting bottlenecks and the impact of variability. Monte Carlo simulations quantify risk by running many random trials to reveal likely outcomes under different load and capacity assumptions. Digital twins—virtual replicas of the production system—offer dynamic, real-time insights and what-if analyses for proposed changes. While these tools require data and expertise, they pay back with clearer decision support, quicker experimentation, and lower implementation risk.

Case Study: Assembly Line Scenario

Consider an imagined six-station assembly line that processes a family of products with varying complexity. A new module slows one station slightly, increasing cycle times and reducing local capacity. The team models the impact, identifies the bottleneck, and explores options: redistribute tasks to other stations, add a parallel line segment, or adjust the product mix to reduce peak demand at the affected station. Each option is evaluated for impact on throughput, queue lengths, and maintenance load. The outcome shows that a modest process rebalancing and a targeted equipment upgrade yield the best return with limited downtime, illustrating how load-capacity thinking drives concrete improvements.

Risk Management: Safety, Redundancy, and Compliance

Balancing load and capacity has direct safety implications. Overloading assets increases the risk of wear, fracture, and sudden failures. Redundancy—spare capacity, cross-trained teams, and backup power—reduces the probability of a single-point failure cascading into a shutdown. Compliance with safety standards and industry guidelines remains a central concern; capacity planning should never compromise safety margins or require unsafe shortcuts to meet demand. A proactive risk management mindset uses scenario planning, regular audits, and clear escalation paths to catch issues before they affect performance.

Economic Considerations: Cost and ROI

The economics of load-capacity decisions hinge on trade-offs between capital expenditure, operating costs, and risk. A load-driven approach often lowers upfront costs but can incur higher operating expenses as capacity is strained or expanded reactively. Capacity-driven designs demand more capital but typically offer greater long-term stability, predictable maintenance, and smoother production rates. A balanced approach seeks to minimize total cost of ownership by aligning investments with anticipated variability, expected demand, and the cost of downtime. Transparent financial modeling helps leadership weigh options and justify the chosen path over the life of the system.

Industry Standards and Best Practices

Across industries, practitioners converge on several core practices for load-capacity management: define clear performance targets, document measurement methods, validate models with real data, and maintain robust change management. Use standardized terminology to avoid miscommunication among engineering, operations, and finance teams. Regularly review capacity plans against actual performance and adjust for new product introductions, process improvements, and supplier changes. While standards evolve, the principle remains consistent: decisions should be evidence-based, repeatable, and auditable.

Implementation Roadmap: From Assessment to Action

Start with a structured assessment: catalog current load, capacity, and constraints; map process flows; and identify critical bottlenecks. Build a simple model to simulate baseline performance and test alternative scenarios. Validate model predictions with pilots or staged deployments. Develop an action plan that prioritizes changes with the highest expected impact on throughput and reliability, including timelines, risk controls, and budgets. Implement incrementally, monitor results with live data, and adjust as needed. A disciplined, iterative approach reduces risk and accelerates the benefits of load-capacity optimization.

Quick Decision Framework: When to Prioritize Load vs Capacity

If demand is highly volatile and product mixes change frequently, favor a load-responsive, modular capacity strategy. If demand is predictable, stable, and high-volume, invest in capacity scaling and long-term infrastructure to maximize throughput. In many environments, a hybrid approach—balance with responsive load signaling and scalable capacity—delivers the best balance of agility and reliability. Always anchor decisions in real data and safety requirements, and revalidate choices as conditions evolve.

Comparison

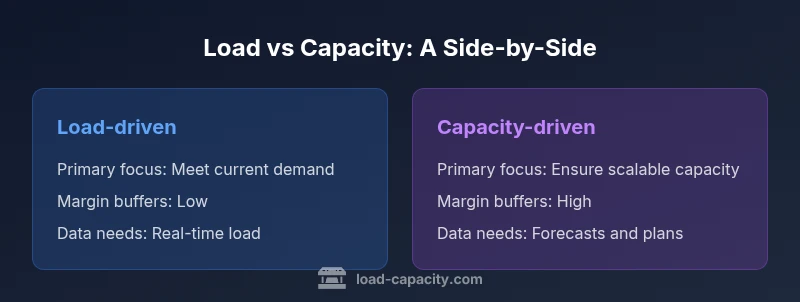

| Feature | Load-driven approach | Capacity-driven approach |

|---|---|---|

| Primary focus | Meet current demand with existing resources | Ensure long-term capability with scalable resources |

| Margin buffers | Low margin buffers, high flexibility | High margin buffers, investment in redundancy |

| Time to react | Faster adjustments via load monitoring | Longer lead times for capacity expansions |

| Data requirements | Real-time load data and utilization | Forecasts and capacity plans |

| Best for | High variability and small batches | High throughput and stable demand |

Positives

- Faster deployment and lower upfront capital

- Greater flexibility for shifting product mixes

- Better responsiveness to short-term demand swings

- Lean initial asset base

Cons

- Higher risk of bottlenecks during peak demand

- Longer-term costs from repeated scaling and maintenance

- Coordination complexity across functions

Hybrid approach is generally preferable.

Hybrid planning minimizes bottlenecks while preserving flexibility. Load Capacity's verdict is that aligning real-time load signals with scalable capacity delivers the best balance between agility and reliability.

Quick Answers

What is the difference between load and capacity in manufacturing?

Load is the demand placed on a system, such as units per hour or product mix. Capacity is the maximum sustainable output the system can achieve safely. Aligning the two reduces bottlenecks and improves reliability.

Load is demand; capacity is how much you can safely produce. Align them to avoid bottlenecks.

Why is balancing load and capacity important?

Balancing load and capacity helps prevent unexpected downtime, quality issues, and safety risks. It also supports stable planning and better use of capital. A misalignment often shows up as bottlenecks or wasted capacity.

Balancing load and capacity prevents stoppages and keeps quality high.

How can I measure load on a production line?

Use real-time data from sensors and MES systems to track throughput vs capacity. Key metrics include utilization, WIP levels, and queue lengths. Validate measurements with operators to ensure accuracy.

Track throughput and utilization with sensors and operator input.

What are common signs of misalignment?

Frequent bottlenecks, rising maintenance events, and volatile quality metrics signal misalignment. If throughput is inconsistent, it may indicate either load spikes or capacity constraints.

Bottlenecks and quality swings often indicate misalignment.

Can simulation aid load-capacity decisions?

Yes. Simulation models—DES, Monte Carlo, or digital twins—allow scenario testing without disrupting operations. They help quantify risks and prioritize changes before implementation.

Simulation helps test scenarios safely before changes.

Should I pursue a hybrid load-capacity strategy?

In most environments with variability, a hybrid approach offers resilience and efficiency. It combines real-time load signaling with scalable capacity to adapt to demand.

Hybrid strategies balance flexibility and reliability.

What role do margins play in capacity planning?

Margins provide safety against unexpected demand or disruptions. They reduce the risk of performance dips but require upfront investment and planning.

Safety margins reduce risk but cost more upfront.

How often should capacity plans be reviewed?

Capacity plans should be reviewed regularly, at least quarterly, and after major process changes or shifts in demand. Real-time monitoring should feed these reviews.

Review plans quarterly and after big changes.

Top Takeaways

- Balance load and capacity through measurement and planning.

- Use modular, scalable capacity to absorb variability.

- Monitor performance with real-time data and feedback loops.

- Apply simulations to test changes before implementing them.

- Prioritize safety margins and risk controls in all decisions.