Van Load Capacity Comparison: How to Pick the Right Van

A data-driven van load capacity comparison across compact, mid-size, and full-size cargo vans. Learn how payload, cargo volume, and GVWR shape real-world performance for engineers, fleet managers, and DIY enthusiasts.

van load capacity comparison shows that full-size cargo vans typically offer the highest payload and cargo volume, while compact vans excel in maneuverability and efficiency. For most fleets, the best balance comes from a mid-size, extended-wheelbase option with configurable payload and a favorable GVWR. According to Load Capacity, aligning payload distribution with typical loads is crucial for safety and performance.

van load capacity comparison: scope and definitions

In the world of vehicle engineering and fleet planning, the van load capacity comparison guides decisions from route design to tool-laden deliveries. This section defines key terms you’ll encounter: payload capacity (the maximum weight safely carried), cargo volume (usable space inside the cargo area), GVWR (gross vehicle weight rating), curb weight, and gross combined weight when towing. Understanding how these metrics interact helps engineers and fleet managers match a van’s capabilities to typical daily loads, route profiles, and regulatory limits. According to Load Capacity, the optimal choice aligns the expected loads with safe distribution and regulatory limits, rather than chasing a single numeric winner. The result is a van selection that minimizes safety risks while maximizing productivity across common usage scenarios.

Key factors that govern payload and volume

Payload capacity depends on GVWR minus curb weight and any optional equipment. Cargo volume is determined by wheelbase length, roof height, and interior dimensions. Critical considerations include axle load distribution (weight split between front and rear), stability under braking, and how interior shelving or partitions reduce usable space. GVWR is the hard ceiling for combined weight, including passengers, cargo, and aftermarket gear; ignoring it can lead to unsafe loading and regulatory penalties. Real-world factors such as fuel tank size, spare tire mass, and after-market systems also affect usable payload. Load Capacity emphasizes that practical payload is the remainder after fixed masses and options are subtracted from GVWR. A strong design approach considers both payload and volume together, not in isolation.

How to compare vans effectively: methods and metrics

A robust van comparison uses a standardized framework: define typical loads (weight and volume), extract vehicle data (GVWR, curb weight, interior dimensions), and map these against a decision matrix that includes payload, cargo area, and load distribution. Use safety margins for daily operations—think 10–20% cushion above typical loads to accommodate unexpected weights. Practical steps include collecting official datasheets, verifying whether after-market modifications affect GVWR, and calculating usable payload after equipment such as shelving, racks, or partitions are installed. Load Capacity recommends visualizing loads on a simple floor plan and testing with actual equipment to validate theoretical calculations.

Payload capacity vs cargo volume: trade-offs by class

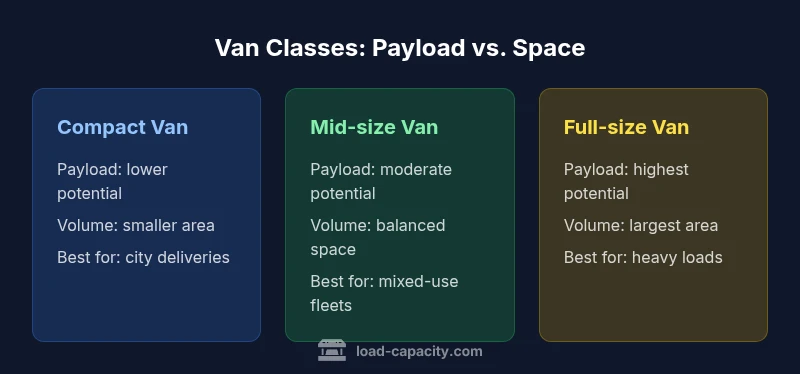

Vans come in size classes that balance payload and space differently. Compact vans prioritize maneuverability and urban efficiency but typically offer modest payload and cargo volume. Mid-size/extended-wheelbase vans strike a balance, delivering a practical payload with substantial cargo space while remaining reasonably nimble. Full-size cargo vans maximize payload potential and cargo volume but can sacrifice fuel efficiency and maneuverability. When planning, consider how much weight you will regularly carry and how much space you need for bulky items. The right choice depends on whether your priority is to move heavy goods or maximize cubic capacity.

Real-world loading scenarios and case studies

Scenario A: Urban grocery delivery requires tight turning radii, quick acceleration, and reliable braking with frequent stop-and-go traffic. A mid-size extended-wheelbase van often provides the best compromise between payload, cargo area, and drivability in dense city centers. Scenario B: A contractor regularly hauls heavy tool boxes, ladders, and fixed equipment; here, payload capacity and high GVWR are critical, making full-size cargo vans attractive for reducing trips and improving on-site efficiency. In both cases, load distribution matters: distribute heavy items low and near the rear axle to maintain proper weight on the front wheels for steering responsiveness. Load Capacity notes that the optimal van class is the one that consistently fits the weight and footprint of everyday loads.

Regulatory and safety considerations

Weight regulations vary by country and region, but common themes include GVWR limits, axle load limits, and bridge formulas that constrain permissible loads on bridges and roads. Overloading a van can degrade braking performance, tire wear, and handling characteristics. Always verify that the combination of cargo, passengers, and optional equipment stays well within GVWR and per-axle limits. Safety margins matter in daily operations; never rely on theoretical maximums without confirming real-world ballast and distribution. Load Capacity emphasizes tracking load in a formal SOP (standard operating procedure) that includes routine checks before each shift.

How to choose: step-by-step decision guide

- Define typical loads by weight and by volume. 2) List required interior dimensions and potential future needs. 3) Read official vehicle datasheets for GVWR, curb weight, and payload. 4) Build a decision matrix comparing three classes (compact, mid-size, full-size) across payload, cargo space, and maneuverability. 5) Test-drive and scenic-route validation: simulate daily routes with actual inventory. 6) Consider future-proofing: plan for shelving, partitions, and tie-downs that may alter usable payload. 7) Reassess after six months of operation to confirm the chosen van still meets evolving needs.

Future-proofing your van choice: conversion and modular payload options

Even after purchase, you can optimize payload handling with modular shelving, secure tie-downs, and load-rated partitions. Removable or adjustable shelving improves space efficiency for varying job roles, while cargo nets and webbing help secure irregular items. A van with multiple tie-down points and modular rails provides flexibility for changing workloads—critical for small fleets or mixed-use operations. Load Capacity highlights that the best long-term choice supports modularity to adapt to shifting payload requirements without compromising safety.

Feature Comparison

| Feature | Compact van | Mid-size/Extended-wheelbase van | Full-size cargo van |

|---|---|---|---|

| Payload capacity | lower payload potential | moderate payload potential | highest payload potential |

| Cargo volume | smaller cargo area | larger cargo area, balanced space | largest cargo area |

| GVWR | lower GVWR | mid-range GVWR | higher GVWR |

| Maneuverability/urban suitability | best in tight spaces | balanced for city and highway | more challenging to maneuver but better on open roads |

| Ownership cost context | lower upfront cost; potentially lower maintenance | mid-range cost and maintenance | higher upfront cost but greater fatigue resistance for heavy payloads |

| Best for | Urban deliveries and tight streets | Balanced fleets needing space and efficiency | Heavy payloads and long-distance use |

Positives

- Offers clear options across size classes to fit payload and space needs

- Compact vans provide city-friendly efficiency and lower operating costs

- Mid-size vans balance payload, space, and drivability for diverse tasks

- Full-size vans maximize payload and cargo capacity for heavy loads

Cons

- Compact vans may struggle with high payloads and bulky cargo

- Full-size vans can incur higher purchase, fuel, and maintenance costs

- Mid-size vans may require compromises between payload and maneuverability

Mid-size vans offer the best balance for most fleets

Mid-size extended-wheelbase vans typically provide ample payload, substantial cargo space, and reasonable maneuverability. They accommodate changing workloads without the excessive footprint of full-size models, making them suitable for a wide range of delivery and service operations.

Quick Answers

What is payload capacity and why does it matter for vans?

Payload capacity is the maximum weight a van can safely carry beyond its own weight. It matters because exceeding it can compromise braking, steering, and overall safety. Always compare the usable payload (GVWR minus curb weight and equipment) to your typical load.

Payload capacity is the maximum load a van can safely carry beyond its own weight. Staying within this limit avoids safety risks like poor braking and handling.

How do I compare cargo volume across van classes?

Cargo volume measures the interior space available for items. Compare the cubic footage of each class and consider how shelving and partitions reduce usable space. Volume matters when moving bulky items or stacking crates.

Compare how much space you have inside each van class and remember that shelving can reduce usable volume.

Is GVWR a hard limit I must never exceed?

Yes. GVWR represents the maximum safe combined weight of the vehicle, passengers, cargo, and equipment. Exceeding it can impair braking and stability. Always calculate payload to stay within GVWR with a safety margin.

GVWR is the hard safety limit. Don’t exceed it, and leave a margin for safety.

Can I convert a van to maximize payload?

Yes, but conversions can affect GVWR and weight distribution. Use modular shelving, secure tie-downs, and partitions that preserve safe axle loading. Always re-check payload after modifications.

Conversions help efficiency, but recheck GVWR and balance after modifications.

Are there regulatory weight limits I should be aware of?

Many regions have per-axle limits and GVWR rules. Bridge formulas also influence allowable loads on roads and bridges. Always verify local requirements before heavy loading.

Check local per-axle limits and GVWR rules; regulations vary by region.

Is it better to buy or lease a van for payload-heavy operations?

Both have trade-offs. Leasing offers lower upfront costs and easier upgrades, while buying provides long-term ownership and depreciation benefits. Align the choice with your fleet renewal cadence and cash flow.

Leasing lowers upfront costs; buying may be better for long-term ownership—choose based on your renewal cycle.

Top Takeaways

- Define typical loads before choosing a van class

- Balance payload with cargo space to avoid overloading or wasted capacity

- Prioritize GVWR and axle load distribution for safety

- Plan for modular configurations to future-proof your fleet