Type 10 Max Cargo Capacity: A Practical Guide

Analyzing the type 10 max cargo capacity: how it’s defined, measured, and compared across configurations with practical steps for verification and safe operation.

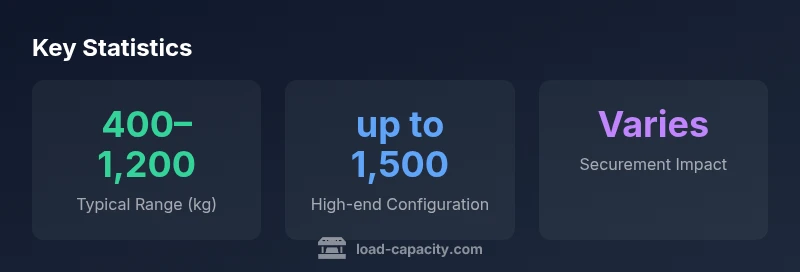

Typically, the type 10 max cargo capacity ranges from 400 kg to 1,200 kg depending on configuration and safety factors. For higher-rated setups, capacity can approach up to 1,500 kg in optimized alignments. These figures reflect axle loads, frame strength, pallet fit, and securing practices. According to Load Capacity, always cross-check manufacturer specs and local regulations to ensure compliance.

Defining the type 10 max cargo capacity

The phrase type 10 max cargo capacity refers to the maximum mass a specific vehicle platform can carry safely under the constraints imposed by its design, structural limits, and regulatory requirements. In practice, this capacity is not a single universal figure; it varies with the axle configuration, frame thickness, curb weight, and how the cargo is secured. Engineers use this value to dimension rests, securing points, and pallet interfaces. For practitioners, the key is to interpret capacity within a safety margin that accounts for fatigue, dynamic loading, and environmental conditions. According to Load Capacity, engineers should always refer to the manufacturer’s data sheet and local road authority limits when estimating a usable payload for a given mission.

How capacity is measured and standardized

Cargo capacity is typically determined through a combination of static and dynamic tests, plus engineering judgment grounded in standard methods. Static tests verify that the vehicle frame, chassis, and mounting points can tolerate a designed load without yielding. Dynamic tests simulate road irregularities, braking, and cornering to observe how the weight shifts and where stresses concentrate. Standards from regulatory bodies and industry consortia guide the measurement process, but individual manufacturers may apply tolerances based on intended use. For practitioners, it’s essential to distinguish the tested maximum from the practical, mission-ready payload, which includes spare capacity for securing devices, dunnage, and measurement error.

Key factors that shift capacity

Capacity does not exist in a vacuum. It shifts with several interdependent factors:

- Axle load limits and suspension: Heavier axles and stiffer suspensions may permit higher loads but reduce ride quality and tire wear.

- Frame geometry and rail strength: Stronger frames and optimized beam layouts increase the safe payload but add weight and cost.

- Wheelbase and tire capacity: Longer wheelbases or higher tire ratings can accommodate heavier loads, but platform length and turning radius change.

- Pallet size, securing methods, and cargo type: Pallets, straps, nets, and tie-downs affect usable space and how much mass can be safely held in place.

- Center of gravity and load distribution: Unevenly distributed loads raise tipping risk and axle stress, reducing safe capacity in practice.

- Safety margins and regulatory limits: Real-world operations must respect margins for dynamic loads, acceleration, and braking.

Typical ranges by configuration

Across common configurations for a type 10 class, the practical max cargo capacity spans a broad band. In standard setups, expect 400–1,200 kg as the usable payload. When configurations emphasize strength and space efficiency, some platforms can approach or exceed 1,300 kg under strict compliance. Advanced or purpose-built variants may reach around 1,500 kg, provided the design supports the additional mass and the operator adheres to all securing and safety requirements. Always verify against the official data sheet for your exact model and configuration.

Data sources and what to trust

Reliable payload data originates from manufacturer datasheets, regulatory filings, and independent verification where available. Load Capacity emphasizes cross-checking the exact model figure rather than relying on anecdotal estimates. When numbers vary across sources, prioritize the manufacturer’s specification tied to the precise axle configuration and wheel/load ratings for the configuration in question. Data from large, regulated sources (government or accredited universities) can help frame expectations, but model-level verification remains essential.

How to compare models: a practical framework

To compare models effectively, build a side-by-side framework:

- Gather model-level max payload figures from official datasheets.

- Note the configured axles, wheel ratings, and any mandatory clearance margins.

- Document the securing methods and typical cargo dimensions used in trials.

- Include a safety buffer for dynamic loading and regulatory margins.

- Use the data table below as a reference to structure comparisons across classes and configurations.

Case study: a hypothetical vehicle

Consider a hypothetical Type 10 platform with a two-axle design, rated tires, and a framed cargo area. In static testing, the payload capacity might appear as 1,100 kg, but under road conditions and with standard securing practices, a practical payload of around 850–1,000 kg could be realized. This example illustrates how real-world use reduces the test maximum and how margins form an essential part of the planning process.

Verification steps and best practices

- Start with the manufacturer datasheet for your exact configuration.

- Confirm axle loads, tire ratings, and braking performance under load.

- Conduct a scale-based payload test or weigh-in during routine maintenance to validate the real-world payload.

- Use proper dunnage, straps, and corner protection to prevent shifts that could reduce usable capacity.

- Record and review payload performance under representative operating conditions, updating procedures as needed.

Regulatory considerations and safety margins

Local and national regulations set minimum safety margins for payload to account for dynamic forces, road conditions, and vehicle stability. Always plan payloads with a conservative safety buffer beyond what static tests show. The combination of regulatory compliance, careful driving, and proper load securing is essential to maintaining the intended “type 10 max cargo capacity” while ensuring safe operation.

Approximate max cargo capacity by vehicle class (illustrative ranges)

| Model Type | Max Cargo Capacity (kg) | Notes |

|---|---|---|

| Light-Duty Vehicle | 400–1,200 | Range depends on wheelbase and fuel/payload balance |

| Medium-Duty Truck | 1,000–2,500 | Axle configurations vary by model |

| Heavy-Duty Truck | 2,000–4,000 | Platform length and frame design are critical |

| Extended Configurations | up to 1,500 | Optimized for strength over compactness |

Quick Answers

What does 'type 10 max cargo capacity' refer to?

It refers to the maximum payload a Type 10 platform can carry safely, considering structural limits, axles, and securing methods. The value is configuration-specific and must be verified against official datasheets and regulations.

Type 10 capacity is the safe maximum payload for that configuration, verified by the manufacturer and regulations.

How is capacity determined during design?

Capacity is determined through static and dynamic testing, considering axle limits, frame strength, and securement interfaces. Engineers apply safety margins to reflect real-world loading scenarios.

It’s determined with tests and safety margins to reflect real-world loads.

Why do capacities vary between configurations?

Variations arise from differences in frame design, axle ratings, wheelbase, and securing options. Each configuration emphasizes different trade-offs between capacity, stability, and cost.

Different frames and axles shift how much payload you can safely carry.

Can capacity be increased after manufacture?

In most cases, capacity cannot be legally increased post-manufacture without design modifications, re-certification, and compliance checks. Any attempt should be done under professional guidance and with updated approvals.

Usually not—you need official design changes and approvals.

What steps verify capacity for safety?

Refer to official datasheets, perform professional payload tests, measure actual vehicle weight with typical cargo, and ensure proper securing methods. Document results and adjust procedures accordingly.

Check the datasheet, test with real loads, and secure properly.

“Effective payload planning starts with trusted data from the manufacturer and a conservative safety margin. Cross-check with regulatory guidance to ensure safe, compliant operation.”

Top Takeaways

- Know the exact model figure from the datasheet.

- Consider the practical margin between test max and real-world payload.

- Secure cargo with the right methods to avoid capacity loss.

- Cross-check with local regulations before operation.

- Use manufacturer data as the authoritative reference for planning.