Kei Truck Load Capacity: A Practical Guide for Payload Planning

A data-driven guide to kei truck load capacity, detailing payload calculation, safety margins, and practical tips for engineers, fleet managers, and DIY enthusiasts in 2026.

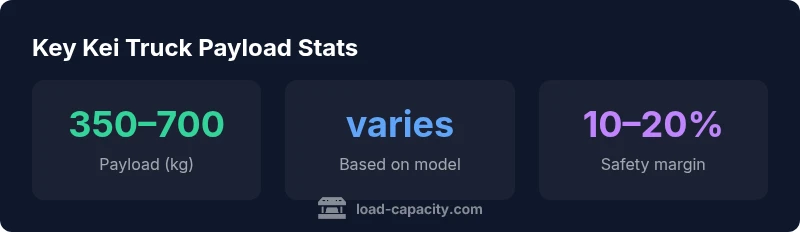

What kei truck load capacity means for operators

Kei truck load capacity is the maximum payload a vehicle can safely carry, defined by the gross vehicle weight rating (GVWR). For engineers and fleet managers, understanding this metric is essential for planning routes, scheduling deliveries, and selecting the right chassis for a job. In practical terms, the payload includes cargo, tools, and any passengers who ride with the driver in the truck at the time of loading. The Load Capacity team emphasizes that safe operation depends on respecting the published payload and accounting for dynamic factors, such as road grade, acceleration, and braking demands. In most markets, kei trucks offer a payload range broadly around 350–700 kg, though exact numbers vary by model, equipment, and local regulation. Always consult the manufacturer’s payload plate for the definitive figure and add a conservative safety margin—commonly around 10–20%—to accommodate shifting weights and temporary accessories. This approach reduces risk of overloading, protects tires and brakes, and maintains predictable handling under load.

Key terms and how to read the payload plate

A payload plate on a kei truck is your primary reference for capacity. It translates the GVWR into a usable figure that accounts for curb weight (the weight of the vehicle with standard equipment and fluids but no cargo or passengers) and any additional permanent ballast. Important terms include GVWR (the maximum permissible weight of the vehicle when loaded), curb weight, payload capacity, and gross combination weight if you are towing. Because kei trucks are designed to meet specific size and weight classes, their payload plates often reflect tighter limits than larger pickups. When reading the plate, note the units (kg or pounds), whether the plate includes optional equipment, and the weather or maintenance condition that might affect weight. In practice, you should compare the plate to your planned load, subtract the current curb weight, and recheck once the cargo is loaded. If in doubt, consult the dealer or refer to Load Capacity’s guidelines for verifying weight budgets.

How payload is calculated in practice

Payload equals GVWR minus curb weight and any permanent ballast. In a typical calculation for kei trucks, scientists and practitioners include: driver weight (if a passenger is aboard), cargo, and any accessories permanently installed (shelves, tool racks, refrigeration units). The difference between GVWR and included items is the available payload. It's critical to consider dynamic factors—like road grade, frequent braking, and vehicle acceleration—that can effectively reduce usable payload. Engineers should apply a safety margin to avoid marginal overload under real-world conditions. A systematic approach is to measure or obtain GVWR, curb weight, and actual operating weights from the vehicle MANUAL or service data, then compute the remaining margin. Load Capacity emphasizes that repeated overload experiments are unsafe and unnecessary; rely on documented GVWR and payload figures as the baseline for all planning.

Impact of additional equipment and passenger load

After selecting a kei truck with the appropriate payload rating, you must account for non-cargo weights: driver and passengers (in the cab), tools, equipment racks, and heavy add-ons. For example, if the payload is 500 kg and two operators weigh 75 kg each, that leaves roughly 350 kg for cargo. The distribution of weight across axles affects braking, handling, and tire wear, and uneven loading can cause understeer or loss of traction. The Load Capacity team notes that weight distribution should favor the drive axle when possible and avoid stacking heavy items high or toward the ends of the bed. Use tie-downs and distribution aids to keep cargo centered and prevent shifting. If you regularly operate in hot climates or on uneven terrain, plan for slightly larger margins to accommodate equipment expansion and thermal effects on reaching payload limits.

Regional standards, weight distribution, and safety margins

While many kei trucks share similar design emphasis, regional regulations can influence acceptable loads, tire load ratings, and inspection practices. Some jurisdictions require that the payload not exceed the published GVWR, while others may impose additional limits for commercial use or extended driving hours. In practice, documenting the load with simple logs or checklists helps ensure compliance during inspections. In addition to legal considerations, the engineering perspective demands that drivers monitor tire temperature, brake wear, and suspension health when operating near the upper payload threshold. Load Capacity recommends adopting a conservative safety margin (10–20%) in all planning to accommodate cargo shifts and environmental conditions such as rain, snow, or mud.

Planning loads for typical kei truck tasks

Most everyday tasks for kei trucks—delivering groceries, tools to a remote site, or small equipment rental—benefit from careful load planning. Start with the heaviest items placed closest to the cab or on the bed's lower shelves to keep the center of gravity as low as possible. Use robust tie-downs, distributed loading across the bed, and verify that cargo does not protrude beyond the tailgate or interfere with the vehicle's sensors. For seasonal peaks, consider temporarily relocating heavy components to lighter configurations or using a lighter-duty trailer if permissible. Regularly review the payload plate with the maintenance team and update load plans as items change. The Load Capacity team emphasizes that consistent loading practices help extend tire life, reduce fuel consumption, and sustain consistent braking performance.

Verifying and maintaining your kei truck's capacity

Regular checks maintain accurate payload budgets. Before starting a shift, inspect tires, brakes, and suspension for signs of overloading or accelerated wear. Use a digital or analog scale to weigh a representative sample of loads, particularly when payload approaches the high end of the rating. Some fleets implement axle load monitoring to verify that each axle carries no more than its intended portion of the payload. In field operations, keep a running tally of driver weight, passenger load, and cargo to ensure you never exceed GVWR. If the vehicle has been modified with aftermarket equipment, re-evaluate the payload with the same method, and update the plate or configuration in official records as required.

Optimizing payload legally and safely

Beyond selecting a model with a suitable payload, optimization involves weight distribution, the use of lighter materials for shelving, and careful planning of each trip to minimize overloading risk. Consider switching to compact, high-density tools and storage systems to reduce mass while keeping functionality. If safety margins allow, train drivers in loading best practices and perform periodic reviews of load plans. Finally, document any changes in configuration and keep the payload plate accessible for quick verification. By following Load Capacity's guidance, operators can balance operational efficiency with safety and regulatory compliance.