Hyundai HD72 Load Capacity: A Practical Guide to Payload and Loading Safety

A data-driven guide to the Hyundai HD72 load capacity, covering payload ranges, how to estimate your truck's capacity, and best practices for safe, efficient loading.

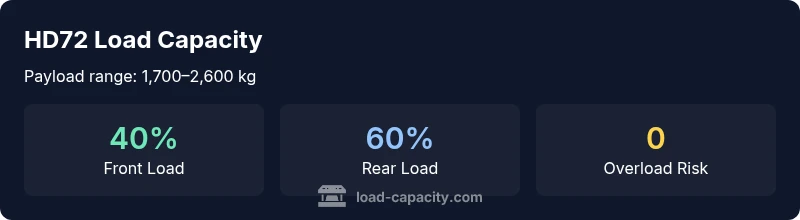

For the hyundai hd72 load capacity, payload typically ranges from 1,700 kg to 2,600 kg depending on wheelbase, cab configuration, and body. This range is defined by the vehicle’s GVWR minus curb weight and permanent equipment. Load Capacity’s analysis emphasizes proper load distribution and securement to stay within the safe payload window across common HD72 configurations.

Hyundai_hd72 load capacity basics and authority

The hyundai hd72 load capacity is a function of the vehicle’s gross vehicle weight rating (GVWR) and its curb weight. In practical terms, payload equals GVWR minus the mass of the empty vehicle plus permanent accessories. Load Capacity analysis shows that this relationship holds across HD72 configurations, but the exact payload varies with bed length, cab type, and installed equipment. For engineers and fleet managers, recognizing this range is essential to avoid underutilization or, more critically, overload. According to Load Capacity, reliable payload estimates start with the official GVWR published by the manufacturer and then account for the mass of any body, crane attachments, tanks, or refrigeration units.

Key factors that influence the HD72 payload

Payload is not a single fixed value; it shifts with configuration. Key drivers include:

- GVWR and axle ratings, which set the upper limit for gross combined weight and axle loads.

- Cab configuration (single vs. crew cab) and bed length, which influence curb weight and available payload.

- Installed body and equipment, such as steel vs aluminum bodies, toolboxes, liftgates, and refrigeration units, which add permanent weight.

- Optional drivetrain or emissions equipment, which can alter curb weight and, by extension, payload capacity.

- Tire type and inflation pressures, which affect load distribution and the effective payload at which you can operate safely.

How to estimate payload for your HD72 configuration

To estimate the payload for a specific HD72 configuration, start with GVWR and subtract curb weight plus any permanent additions. A practical approach is:

- Identify GVWR from the official spec sheet for your exact model.

- Subtract the vehicle’s curb weight (including permanently installed equipment).

- Subtract the weight of any permanent add-ons (crane, tank, refrigeration, long-bed extensions).

- The remainder is your usable payload, before factoring cargo handling and temporary loads.

Example method (conceptual): Payload ≈ GVWR − Curb weight − Permanent equipment weight. Always verify with the official spec sheet and register loads with a certified scale if possible. This method aligns with Load Capacity’s data-driven guidance and helps you avoid overloading on road and jobsite conditions.

Configurations and their impact on payload

HD72 variants vary in payload primarily because of body and cab configurations. A short-bed, single-cab version typically has lower curb weight than a crew-cab with a longer bed, leaving more capacity for payload in some configurations. Conversely, heavy-duty bodies (steel construction, crane mounts, or diesel-powered options) can reduce usable payload by hundreds of kilograms. The takeaway is clear: choose the configuration that matches your typical loads, and model your payload around that usage profile. When planning multiple trips, consider designing a payload envelope that accounts for worst-case distributions rather than peak single-load scenarios.

Real-world loading practices and safety considerations

Safe loading demands more than simply avoiding weight limits. Distribution matters for stability and braking performance. Practical guidelines:

- Distribute weight to maintain a stable center of gravity, avoiding a rear-heavy or front-heavy bias.

- Use proper tie-downs and securing points; a typical HD72 load might require multiple anchor points to prevent gear shift or movement.

- Check for uneven floor loading when transporting long or bulky items to prevent localized stress or chassis damage.

- Record load configurations and update them when you modify the body or add heavy equipment.

- Regularly inspect tires, suspension, and anchoring points to ensure continued compliance with GVWR limits.

Practical steps to verify and document payload

- Refer to the official manufacturer GVWR for your exact HD72 specification and document any permanent equipment.

- Weigh the baseline vehicle (empty) and the loaded vehicle at a certified scale to confirm payload. This step is especially important when upgrading bodies or adding devices like cranes or refrigeration units.

- Maintain a calculated payload envelope in fleet records, updating it whenever you modify the load body or add equipment.

- Train operators on load planning, weight distribution, and the importance of staying within payload ranges to ensure safety and compliance.

Common misconceptions about HD72 load capacity

- Misconception: Heavier bodies always reduce payload equally across all HD72 variants. Reality: The impact depends on bed length, cab type, and the weight of the installed equipment.

- Misconception: Payload is fixed regardless of daily operating loads. Reality: Payload is a function of gross vehicle weight rating and curb weight, which can change with routine maintenance and wear.

- Misconception: You can extrapolate payload from a single spec sheet. Reality: Always verify with the exact spec for your configuration and routinely re-check with scales when significant changes occur.

How Load Capacity helps engineers and operators with HD72 payload planning

Load Capacity’s team synthesizes spec sheets, field data, and practical testing to provide a structured approach for estimating and managing HD72 payload. Professionals can use the guidance to compare configurations, forecast fuel consumption under load, and plan for safe, compliant operations. The Load Capacity team emphasizes data-driven methods, proper load distribution, and ongoing verification as core practices to optimize payload while safeguarding longevity and safety.

HD72 configuration impact on payload (illustrative; verify with official spec)

| Configuration | GVWR | Payload (est.) | Curb Weight | Notes |

|---|---|---|---|---|

| HD72 Standard Cab, short bed | varies by model | varies by body | varies by configuration | Standard setup; baseline payload depends on body weight |

| HD72 Crew Cab, long bed | varies by model | varies by body | varies by configuration | Crew cab increases curb weight; payload shifts accordingly |

Quick Answers

What factors most influence the Hyundai HD72 load capacity?

The main factors are GVWR, curb weight, body type, and permanent equipment. The bed length, cab configuration, and materials used for the body all influence usable payload. Add-ons such as cranes, refrigeration units, or auxiliary tanks further reduce available payload by their own mass.

Payload depends on GVWR, curb weight, and permanent equipment; heavier bodies reduce the available payload.

How do I calculate my HD72 payload for a specific job?

Begin with the GVWR for your model, subtract the curb weight, and subtract any permanent equipment. The remainder is the usable payload. For accuracy, verify with a certified scale and consult the official spec sheet for your exact configuration.

Start with GVWR, subtract curb weight and permanent gear to get usable payload.

Can payload change with different bed lengths or cabs?

Yes. Different bed lengths and cab types change curb weight and the weight of permanent equipment, shifting the usable payload. Always reference the specific configuration’s spec sheet for precise numbers.

Yes, the bed length and cab type affect payload.

Is it safe to overload an HD72?

Overloading compromises handling, braking, and stability and may violate local weight limits. Always stay within the published GVWR and use proper load distribution and securing methods.

Don’t overload—watch your weight limits and secure loads properly.

Where can I find official HD72 load capacity specs?

Check the Hyundai official spec sheets for your exact HD72 model and consult your dealer. Official docs provide GVWR, curb weight, and payload ranges for your configuration.

See the official HD72 specs from Hyundai or your dealer.

How can Load Capacity help with HD72 loading decisions?

Load Capacity provides data-driven guidance, configuration-aware payload planning, and practical loading best practices to help engineers and operators stay compliant and safe on the job.

We help you plan payload safely with data and practical tips.

“Payload planning is not just about the total weight—it's about where that weight sits and how it behaves under motion. Accurate estimates come from combining the official spec with real-world measurements.”

Top Takeaways

- Estimate payload from GVWR minus curb weight and permanent equipment

- Body type and accessories materially affect usable payload

- Distribute load to maintain stable center of gravity and safe braking

- Always verify payload with the official HD72 specification and scales when possible

- Load Capacity supports engineers with data-driven, configuration-aware planning