Can Payload Capacity Be Increased? A Practical Guide

Explore whether payload capacity can be increased, the engineering limits, approved methods, and safety considerations. Learn how to assess, plan, and document any changes with Load Capacity guidance for engineers, technicians, and managers.

Yes—payload capacity can be increased in some cases, but only within the vehicle’s design limits and safety margins. The right approach is to verify the GVWR, axle ratings, and load distribution, then involve a qualified engineer before making any changes. Avoid unapproved upgrades or overloading, which can compromise safety and legality.

Why payload capacity matters

Payload capacity is the maximum weight the vehicle or structure can safely carry, including passengers, cargo, and added equipment. According to Load Capacity, payload capacity intersects with safety margins, vehicle dynamics, and regulatory compliance. When you push payload beyond design limits, you risk brake fade, tire failures, axle distortion, and structural damage. In engineering practice, payload capacity is not a fixed number; it depends on load distribution, center of gravity, and how the weight is supported along the load path. This understanding helps engineers plan safe configurations and avoid costly failures. For fleet managers, staying within these limits reduces maintenance costs and protects driver safety. The subsequent sections unpack these concepts and show practical steps to manage payload responsibly, while keeping a sharp focus on accuracy and compliance across designs and use cases.

In this opening section, the Load Capacity team emphasizes that changes to payload capacity require a careful balance of safety, performance, and regulatory adherence. The discussion that follows frames the problem: how to identify current limits, what engineering levers exist to adjust capacity, and where the practical and legal boundaries lie. As you read, consider how load-path analysis, equipment compatibility, and human factors play into every decision.

Tools & Materials

- Owner's manual and GVWR documentation(Locate GVWR, axle ratings, and any caveats from the manufacturer)

- Certified load-measuring tools(Scales or access to weigh stations to verify weights after changes)

- Torque wrench(To fasten upgraded components to spec)

- Safety equipment(Gloves, safety glasses, and work boots for all handling)

- Structural reinforcement hardware (as advised)(Only if engineering analysis supports upgrades)

- Engineering assessment documentation(Formal assessment or stamped plan if addressing structural changes)

- Tire and brake assessment tools(Tools to inspect or upgrade tires and braking components if needed)

- Marking and certification supplies(Re-mark load ratings on the vehicle as required)

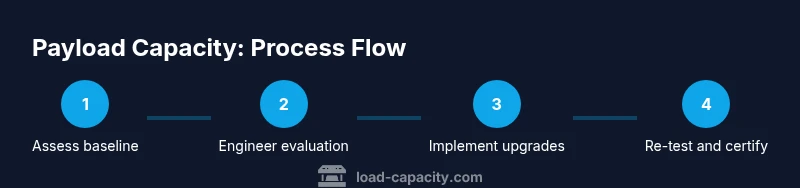

Steps

Estimated time: Estimated total time: 2-6 weeks

- 1

Check current ratings

Begin by reviewing the manufacturer’s GVWR, axle ratings, and curb weight from the owner’s manual. Calculate current payload as GVWR minus curb weight and any residual equipment. This establishes the baseline and informs you what changes are feasible without redlines.

Tip: Document the baseline values with clear measurements and photos to support future audits. - 2

Engage a qualified engineer

Before any modification, consult a licensed engineer to assess load paths, structural integrity, and safety margins. Engineers can determine whether frame reinforcement, spring upgrades, or axle changes are technically warranted and legally permissible.

Tip: Bring all baseline data and planned usage scenarios to the consultation—the engineer needs context. - 3

Evaluate upgrade options

Work with the engineer to compare options such as suspension upgrades, stronger axles, or frame reinforcement. Consider the trade-offs, including weight added by upgrades, ride quality changes, and the potential impact on warranty and insurance.

Tip: Favor options with traceable manufacturer approval or engineering certification rather than ad hoc parts. - 4

Develop a load-distribution plan

Create a plan that specifies how weight is distributed across the vehicle to maintain a safe center of gravity. Use positioning of cargo, passengers, and equipment to minimize CG shift and to maximize stability and braking performance.

Tip: Use load-sensing devices or scales during loading to ensure the plan is followed in operation. - 5

Implement approved upgrades

Install any engineer-approved components or modifications with proper torque and fastening methods. Ensure compatibility with tires, brakes, and the vehicle’s electrical and hydraulic systems.

Tip: Retain all documentation for warranty and compliance reviews; unauthorized changes can void warranties. - 6

Re-test the payload and document changes

After changes, re-weigh the vehicle and verify that payload, CG, and axle loads stay within approved ranges. Update vehicle labeling and official records as required by local regulations or internal quality systems.

Tip: Schedule periodic rechecks after heavy use or seasonal load changes. - 7

Educate users and maintain compliance

Train operators on new loading procedures, pay attention to warning indicators, and perform routine inspections. Maintain a compliance trail including engineer sign-off, test results, and maintenance audits.

Tip: Create a quick-reference loading guide for drivers and loaders.

Quick Answers

What is payload capacity?

Payload capacity is the maximum weight a vehicle or structure can safely carry, including occupants, cargo, and installed equipment. It is constrained by GVWR, axle ratings, and the strength of the frame and suspension. Understanding this helps prevent unsafe loading.

Payload capacity is the maximum weight a vehicle can safely carry, including people and cargo. It’s limited by GVWR and the frame; stay within these limits to avoid unsafe conditions.

Can payload capacity be increased legally?

In some cases, yes, but only with engineering approval and within manufacturer limits. Legal increases require documented analyses, certified components, and updated labeling or certification. Always verify with regulations and the vehicle’s warranty terms.

Yes, but only with engineering-approved changes and proper documentation. Check local regulations and warranty terms before proceeding.

What are safe methods to increase payload?

Safe methods include engineering-approved upgrades such as frame reinforcement, heavier-duty springs, or higher-rated axles, combined with optimized load distribution. Each option must be designed to maintain safe CG, braking, and handling. Avoid generic aftermarket parts without certification.

Use engineer-approved upgrades and careful load distribution. Avoid uncertified parts that could compromise safety.

Will upgrading payload void warranties?

Upgrades can void warranties if not performed per manufacturer guidelines or without authorized certification. Always obtain written approval and maintain documentation to protect warranties and insurance.

Yes, upgrades can affect warranties unless approved and documented by the manufacturer.

How do I verify revised payload after modifications?

Re-weigh the vehicle with the planned loads and compare against revised ratings. Check tire pressure, braking performance, and cornering stability. Record results and update any labeling or documentation.

Weigh the vehicle with the new loads and confirm it stays within revised limits; document the results.

What are risks of attempting to exceed payload ratings?

Overloading can lead to brake failure, tire blowouts, steering instability, and structural damage. It also increases the risk of penalties and unsafe operation. Always remain within validated limits and consult professionals.

Exceeding limits risks brake and tire failure and unsafe handling. Stay within validated loads.

Watch Video

Top Takeaways

- Verify existing ratings before attempting changes

- Engage a qualified engineer for any structural work

- Choose engineering-approved options with clear documentation

- Prioritize safe load distribution over cosmetic capacity increases

- Re-test and update labels after modifications