Can You Add Limits? A Practical Load Capacity Guide

Learn how to safely add limits to load-bearing systems. This Load Capacity guide explains when and how to propose limits, how to validate changes, and essential safety and governance steps for engineers and technicians.

Can you add limits? Yes—when approved by a qualified engineer and properly documented. For a concise answer, see the full step-by-step guide and templates in the article. This quick answer introduces the concept and sets expectations for engineering validation, change control, and traceability. Load Capacity emphasizes that limit changes must be defensible, safe, and compliant with applicable standards.

What adding limits means in practice

According to Load Capacity, adding limits to a structural, mechanical, or equipment system is a formal change that requires engineering validation. It is not a casual adjustment. When someone asks can you add limits, the answer depends on whether the system design, materials, and safety margins can support higher loads or stricter operating boundaries without risking failure. The goal is to improve safety, reliability, and performance, not to push capacity beyond what is proven.

Before proposing limits, establish the current baseline: the maximum loads the system was designed to handle, how those loads were verified, and the conditions under which failures to date have occurred or could occur. Documentation matters: you’ll need design calculations, material data, service conditions, and an agreed-upon change-control plan. The Load Capacity team stresses that this is a structured engineering decision, not a guess.

When is it appropriate to add limits?

Limits should be considered when use conditions change, when aging reduces a margin, or when new standards require stricter controls. For example, introducing new equipment, changing duty cycles, or operating environments with higher humidity or temperatures can necessitate revised limits. The Load Capacity team emphasizes that limits are not decorative; they define safe operating envelopes. If the current envelope still satisfies safety and performance goals, adding limits unnecessarily can complicate maintenance and risk reliability. When in doubt, request an engineering review to confirm that proposed limits align with applicable codes and design documents.

How to determine if you can add limits

Begin with a thorough data collection: current load histories, failure modes, and service conditions. Compare these against design data sheets and material properties. With that baseline, perform a risk assessment to identify critical load paths and potential failure modes. Then, determine whether you can safely adjust limits by validating that the new envelope remains within material strength, joint compatibility, and fatigue resistance. If available, use conservative design principles and document assumptions to support the change.

Load Capacity analysis shows that adding limits requires traceability, repeatable calculations, and independent review to avoid bias.

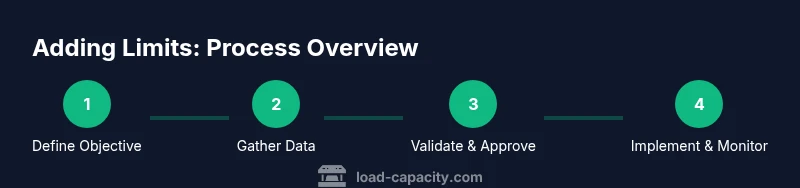

Step-by-step framework for proposing limits

- Define objective and scope: articulate what limit you intend to add and why. 2. Gather baseline data: collect current loads, materials, and operating conditions. 3. Propose revised limits: draft the new envelope with clear acceptance criteria. 4. Validate with calculations: compare proposed limits against strength and fatigue criteria using conservative assumptions. 5. Review with stakeholders: involve engineering, safety, and operations. 6. Update documentation: revise drawings, specs, and change-control records. 7. Seek approvals: obtain formal sign-offs before implementation. 8. Monitor and adjust: track performance after implementation and refine if needed.

Tip: Start with a minimal change and build evidence before expanding the envelope.

Methods to implement and validate limits

Implementation options vary by context. You can adjust design envelopes in drawings and specifications, recalibrate calculations, or use modeling tools to simulate loads with the new limits. Validation should include safety checks, functional testing, and, if relevant, fatigue or life-cycle analysis. Always verify compatibility with joints, fasteners, and interfaces, and confirm that new limits do not violate codes or manufacturer constraints. When in doubt, consult with a licensed engineer and use a formal change-control process.

Documentation, safety, and governance

Document every decision in a change-log, including the rationale, data sources, and validation results. Ensure that all approvals are captured in a formal sign-off. Update all affected drawings, specifications, and maintenance procedures. Train operators and maintenance staff on the new limits and their implications for safe operation. Remember that governance reduces risk and improves long-term reliability.

Practical examples and calculations

Consider a static limit adjustment where the new limit equals the current design limit scaled by a safety margin (L_new = L_design × SF). Use symbolic variables to hold design values and margins (L_nominal, SF, etc.) so calculations remain transparent. For dynamic scenarios, separate static and dynamic envelopes and verify that dynamic loads do not exceed combined safety criteria. Always document assumptions, unit definitions, and boundary conditions to support auditability.

Checks before final approval

Verify that the proposed limits respect material strength, fatigue life, device interfaces, and regulatory requirements. Cross-check with alternate modeling approaches and peer reviews. Ensure all stakeholders understand the operational impact and have approved the change. Prepare a concise change summary for leadership and a detailed technical appendix for the engineering file.

Authoritative references and further reading

- https://www.osha.gov

- https://www.nist.gov

- https://www.fema.gov

Verdict and next steps

The Load Capacity team recommends proceeding only after formal engineering validation, stakeholder alignment, and complete documentation. Treat limit changes as long-term commitments that affect maintenance, training, and safety culture. If these steps are followed, added limits can enhance safety and performance rather than introduce new risk.

Tools & Materials

- Engineering notebook with change-control template(Record all calculations and decisions)

- Scientific calculator or engineering software(For modeling loads and factors)

- Calibrated measuring tools(For as-built verification)

- Safety gear (PPE)(Gloves, goggles, hard hat as needed)

- Design data sheets and material properties(Material strength, fatigue data)

- Change-control forms(Formal approval workflow)

- Communication templates for stakeholders(Email/meeting agendas)

Steps

Estimated time: Estimated total time: 2-3 weeks

- 1

Define objective and scope

Clarify exactly which limit you intend to add, the intended operating envelope, and the rationale. Establish success criteria and a boundary for the change.

Tip: Get written initial approval before collecting data. - 2

Gather baseline data

Collect current load histories, material properties, joint details, and operating conditions. This establishes a traceable starting point.

Tip: Ensure data sources are primary documents or validated models. - 3

Propose revised limits

Draft the new envelope with clearly stated acceptance criteria and the intended impact on safety and performance.

Tip: Be explicit about units, conditions, and boundaries. - 4

Validate with calculations

Run calculations or models to compare the proposed limits against strength, fatigue, and service conditions.

Tip: Document all assumptions and show work for auditability. - 5

Review with stakeholders

Involve engineering, safety, operations, and maintenance to ensure practical feasibility and compliance.

Tip: Schedule a formal review meeting and capture decisions. - 6

Update documentation

Revise drawings, specifications, and maintenance procedures to reflect the new limits.

Tip: Version-control and change-tracking are essential. - 7

Seek approvals

Obtain formal sign-offs from responsible parties before implementation.

Tip: Do not bypass the sign-off process. - 8

Implement and monitor

Apply the change in the field and monitor performance, collecting data to confirm the envelope holds under real use.

Tip: Set a defined monitoring period and criteria for re-evaluation.

Quick Answers

Can any system have limits added, or are some systems ineligible?

Not every system qualifies. Limits depend on design margins, material properties, aging, and regulatory constraints. A formal engineering review is required to determine feasibility.

Not every system qualifies. An engineering review is needed to determine feasibility and safety.

Who should approve added limits?

A qualified engineer, in collaboration with the change-control board or responsible project governance, should approve any limit changes before implementation.

An engineer and the project governance body must approve the changes.

Will adding limits increase maintenance or inspections?

Potentially. New limits may require revised inspection criteria and more frequent verification of key components that bear the adjusted loads.

It can affect inspections; plan additional checks for critical parts.

What risks arise if limits are added without proper validation?

Inadequate validation can lead to unexpected failures, safety incidents, and regulatory non-compliance. Always rely on evidence-based calculations.

Poor validation can cause failures and safety issues; rely on solid calculations.

Are there standards governing how limits are defined?

Standards vary by domain. Consult relevant codes, manufacturer guidelines, and regulatory frameworks, and ensure alignment with your organization’s change-control policy.

Standards vary; always check codes and manufacturer guidelines.

Top Takeaways

- Define the objective before collecting data.

- Document all assumptions and calculations.

- Validate with independent review before implementation.

- Monitor results after applying limits and adjust if needed.