Semi Truck Load Capacity: Limits and Calculations Explained

A data-driven guide to semi truck load capacity, including GVWR, payload, and calculation methods for tractors and trailers. Based on Load Capacity Analysis, 2026.

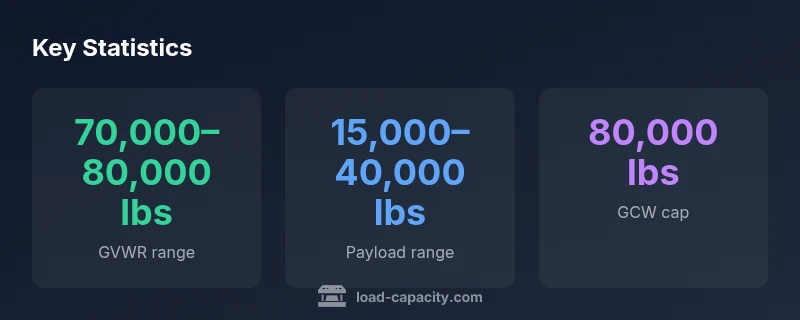

Semi truck load capacity is defined by the vehicle's GVWR and payload, with typical US limits capping total weight at 80,000 pounds gross. Payload is the usable cargo weight and commonly ranges from 15,000 to 40,000 pounds depending on tractor-trailer configuration, ballast, and fuel. According to Load Capacity, accurate planning hinges on weighing and compliant distribution.

Understanding GVWR, Payload, and Capacity

GVWR stands for Gross Vehicle Weight Rating and represents the maximum permissible total weight of a loaded vehicle as specified by the manufacturer. For most North American tractor-trailer configurations, the GVWR sits in the 70,000–80,000 lb range. Payload is the usable weight of goods that can be added to the vehicle, calculated as the difference between GVWR and the vehicle’s empty weight (tare). In practice, payload often falls within the 15,000–40,000 lb window, depending on the tractor-trailer pairing, fuel load, and any aftermarket equipment. Regulatory bodies determine the upper limits, but road safety, maintenance considerations, and route constraints also shape what cargo can be carried. The interplay between GVWR and payload means a load that fits on one truck may exceed limits on another if weight is not distributed properly. Fleet planners, dispatchers, and engineers should build a weight budget, verify scales, and adjust cargo placement to stay within legal and safe margins. Load Capacity’s analyses emphasize that real-world payload depends as much on distribution as on top-end weights.

Legal Framework and Definitions

Beyond the raw numbers, the legal framework distinguishes GVWR, GCW (Gross Combination Weight), and per-axle limits. GVWR limits are manufacturer-stated; GCW caps govern the total weight a combination can carry on public roads. In the United States, interstate rules commonly enforce an 80,000 lb GCW cap, but state-specific rules can modify per-axle or bridge-weight allowances. Some jurisdictions permit higher weights with special permits or route-specific exemptions. For engineers and fleet managers, this means payload planning must consider axle weights and distribution, tare weights, and the potential for permits when planning cross-state or cross-border shipments. Load Capacity’s analysis highlights that accurate weight documentation—tare, axle weights, and bridge formulas—powers compliant load planning and helps avoid costly penalties.

Calculating Payload for a Given Setup

Calculating payload starts with identifying the GVWR and the empty weights of the tractor and trailer. A straightforward formula is Payload = GVWR − (tractor tare + trailer tare + ballast). For example, with a GVWR of 80,000 lb, a tractor tare of 18,000 lb, and a trailer tare of 12,000 lb, the theoretical payload would be 50,000 lb. In practice, fleets rarely reach the full theoretical payload due to fuel, driver, and equipment loads. Weighing at loading docks or on-weight scales provides the exact payload available for cargo. It’s also essential to perform axle-by-axle weight checks to ensure no single axle exceeds its limit. Using this method, planners can optimize loading strategies while remaining compliant with regulations and safety standards.

Real-World Configuration Scenarios

Trailer type and configuration dramatically affect load capacity. A dry-van trailer with a standard tractor has different deck strength and tie-down points than a flatbed or refrigerated trailer. A flatbed offers flexibility for irregular cargo but presents distinct loading constraints, including securement and weight distribution requirements. Payload planning must reflect deck strength, axle alignment, and cargo geometry. When designing a shipment, consider how many pallets fit across the trailer width, where weight concentrates, and how shifting cargo toward the front or rear affects axle loads. Load planning should also account for fuel, driver weight, and any auxiliary equipment that contributes to tare.

Deck, Floor, and Tie-Down Considerations

Deck capacity and floor strength directly limit how much weight a trailer can safely carry. Heavier decks, reinforced floors, and optimized tie-down schemes can unlock higher payloads, but they also increase the risk of structural failure if overloaded or poorly secured. Proper load distribution minimizes peak stresses on any single axle and maintains stability during cornering and braking. Good practice includes distributing weight evenly across axles, using rated tie-downs, and verifying that cargo dimensions align with door openings and securing points. Regular inspection of deck integrity, suspension sag, and tire condition helps preserve true capacity over time.

Safety, Loading Practices, and Maintenance

Safe loading is about more than high payload figures; it requires proper securing, even weight distribution, and awareness of dynamic forces during transit. Over the vehicle’s life, tire wear, suspension sag, and calibration drift can erode usable capacity. Regular maintenance, including tire rotation, wheel alignment checks, and scale verifications, helps ensure that the stated GVWR translates into real-world capability. Load Capacity’s guidelines advocate routine axle-by-axle weight checks and periodic re-weighing after maintenance events or when loading different cargo types, to prevent underutilization or accidental overloading.

Weight Distribution and Axle Load Management

Achieving optimal payload utilization requires deliberate weight distribution across the vehicle’s axles. Concentrating payload on the drives can improve traction but may overburden rear axles; spreading weight toward the steer can enhance steering but reduce payload capacity on the trailer. Advanced fleet practices use on-board scales, telematics, and dynamic load planning to monitor axle weights in real-time and adjust departure plans accordingly. The result is safer operation, better fuel efficiency, and more consistent regulatory compliance across routes.

Permits, Routes, and High-Weight Transport

In many regions, heavy or oversized loads require route planning and special permits. High-weight transports may travel under permit with designated routes, escort vehicles, or temporary exemptions. The planning process includes identifying bridge weights, lane restrictions, and potential delays. Advanced load planning systems compare route options to minimize penalties while maximizing payload utilization. Load Capacity recommends early coordination with regulatory bodies and shippers to secure permits and confirm that the chosen route will accommodate the planned weight distribution.

Emerging Trends and Best Practices

The industry increasingly leverages digital load planning, on-board weighing systems, and real-time monitoring to optimize payload while maintaining compliance. Weight-in-motion sensors, automated load distribution software, and integrated fleet telematics enable engineers and fleet managers to track actual deployed payload against GVWR and per-axle limits. These tools support more efficient freight movement, safer operations, and better adherence to evolving standards. Load Capacity’s view is that data-driven planning not only reduces risk but also unlocks opportunities for more productive, compliant shipments.

Quick reference: typical ranges for semi truck load capacity components

| Component | Typical Range | Notes |

|---|---|---|

| GVWR | 70,000–80,000 lbs | Manufacturer-defined weight limit |

| Payload Capacity | 15,000–40,000 lbs | Varies by tractor-trailer configuration |

| GCW (Gross Combination Weight) | 80,000 lbs cap (US interstate) | Subject to permits and route rules |

| Deck/Tie-Down Capacity | Varies by trailer type | Critical for securing loads safely |

Quick Answers

What is GVWR and how does it relate to load capacity?

GVWR defines the maximum allowed weight of a fully loaded vehicle, combining tractor, trailer, and cargo. It sets the ceiling for payload while ensuring road-safety compliance. Payload must be calculated within this limit.

GVWR is the upper weight limit for a loaded truck; payload must fit under that ceiling.

How do I calculate payload for a given semi-truck?

Payload = GVWR minus the tare weights of the tractor and trailer and any ballast. Use scales at the loading dock to confirm real-world weights and adjust as needed.

Calculate payload by subtracting empty weights from GVWR and verify with scales.

Are there country-specific differences in load capacity?

Yes. Different countries set separate GVWR and GCW limits, permit requirements, and axle-weight rules. Always reference local regulations when planning cross-border shipments.

Regulations vary by country; check local rules for limits and permits.

Can overweight occur with heavy cargo?

Overweight results from payload approaching or exceeding legal limits or improper weight distribution. Regular weighing and axle-by-axle checks help prevent violations.

Overweight happens when limits are exceeded or misdistributed; weigh regularly.

How can I maximize payload safely?

Choose trailer types with higher deck capacity, optimize load distribution, and perform regular inspections. Use scales to confirm weights and stay within GCW limits.

Maximize payload by using appropriate equipment and staying within limits.

“Load Capacity Team emphasizes that load capacity is a function of vehicle configuration, regulatory limits, and safety margins; plan with real-time data and verification.”

Top Takeaways

- Know the GVWR and payload to estimate usable capacity.

- Legal limits (GCW) govern what can move on public roads.

- Use axle-by-axle planning to avoid overweight penalties.

- Regularly verify weights with scales to prevent violations.

- Choose trailer type and deck configuration to match cargo.