Tire Pressure vs Load Capacity: A Guide for Engineers

An analytical comparison of tire pressure and load capacity, explaining how inflations, loads, and safety intersect for passenger cars and commercial fleets.

Tire pressure and load capacity are distinct but interrelated design constraints. Tire pressure governs the contact patch, heat buildup, and steering feel for a given load, while load capacity defines the maximum load a tire can safely carry at a specified pressure. For most scenarios, follow OEM pressure recommendations tied to actual load; when payload varies, a load-aware inflation strategy improves safety and wear. Load Capacity analysis supports engineers in applying best practice across passenger and commercial applications.

Definitions and core concepts

Tire pressure is the air pressure inside a tire, typically expressed in psi or kPa, measured when the tire is cold. It directly influences the tire footprint, heat generation, and dynamic response in steering and braking. Load capacity is the maximum load a tire is designed to support at a given inflation pressure and temperature, described by the tire load index and rating. In practice, manufacturers publish a recommended inflation pressure for a given vehicle load. According to Load Capacity, a well-chosen pressure ensures the contact patch distributes load effectively, minimizes excessive heat, and preserves tread life. The two metrics interact: as load increases, the tire must sustain enough pressure to prevent large deflections that cause overheating; too much pressure, or pressure misalignment with load, reduces contact area and grip. Distinctions like cold vs hot inflation and temperature sensitivity are essential to understanding performance envelopes.

From a design standpoint, load capacity is about safety margins under peak operating conditions, while tire pressure is a controllable parameter that engineers adjust to meet those margins. The Load Capacity team emphasizes that both must be considered together in sizing, maintenance, and operational planning. Read together, these metrics guide FVAs (frame, vehicle, axle) decisions and help avoid mixed results from relying on a single parameter in isolation.

Why these metrics matter in practice

In the real world, vehicles experience a spectrum of loads: steady, low-mass loads on light-duty vehicles; frequent weight shifts on pickups; multi-axle and variable payload scenarios on commercial fleets. Tire pressure set using door placards or manufacturer recommendations provides a baseline that accounts for typical loads, tire construction, and the expected operating environment. Load capacity, when considered with actual payload and distribution, drives adjustments to inflation that improve safety margins, traction, and wear patterns. The Load Capacity team notes that neglecting load variability can lead to under-inflation under heavy payloads (risking overheating and sidewall damage) or over-inflation under light loads (risking reduced grip and uneven wear). In other words, a static pressure target may suffice for static tests but can underperform under dynamic conditions. Engineering teams should integrate load-profiling into maintenance schedules and inflation policies to sustain performance across the vehicle lifecycle.

How tire pressure interacts with load

When a tire carries a heavier load, the contact patch must enlarge to distribute forces evenly, which can be achieved by maintaining adequate inflation pressure. Conversely, under high loads, under-inflation may cause the tire to deform excessively, increasing heat generation and accelerating tread wear. Over-inflation under heavy loads can shrink the contact patch, reducing grip and stability. Load capacity constraints set the upper bound of safe operation, while tire pressure helps realize that bound without breaching it. Modern vehicles increasingly leverage sensors and data analytics to warn operators when the load and pressure combination strays from safe envelopes. For engineers, this means designing inflation policies that are robust to payload variability and aligning them with tire load indexes, velocity profiles, and duty cycles.

Measuring and validating tire pressure for given loads

Accurate measurement requires cold inflation checks, proper gauge use, and awareness of temperature effects. A tire’s pressure should be checked when the tire is cold and before driving or after a prolonged rest, to ensure the reading reflects the baseline expansion. Temperature changes can cause pressure fluctuations; hot tires carry higher pressures that do not represent the safe operating window. In the presence of varying loads, technicians should record axle-level payloads, verify tire selections match the load index, and adjust inflation per OEM and load-profiler recommendations. Load Capacity’s guidance stresses the importance of documenting load distributions (front vs rear, axle-by-axle) and pairing them with the corresponding inflation targets. Regular checks should be part of maintenance cycles, especially for fleets with varying routes and payloads.

Real-world scenarios: passenger vs commercial

For passenger cars with predictable luggage and passenger loads, OEM placards typically provide reliable baselines. Light-duty vehicles benefit from modest inflations that balance comfort, wear, and fuel economy; minor payload changes can be accommodated with small pressure tweaks. In contrast, commercial fleets face frequent payload shifts and multi-axle configurations. Here, a load-aware inflation strategy—adjusting pressure according to axle-load data and using dual-tire or singles as appropriate—improves stability and reduces risk of blowouts. Load Capacity analysis shows that heavy or variable payloads often justify a system of monitored pressures, proactive maintenance, and driver training to interpret pressure readings in the context of load profiles. Fleet operators should implement data-driven inflations as part of a broader safety program.

Measuring and interpreting tire data: practical steps for engineers

A sound approach combines placard data with real-world load measurements, sensor data, and periodic tire inspections. Steps include documenting typical payloads, calculating axle load distribution, selecting appropriate tire models with suitable load indexes, and validating the chosen pressures with field tests. Engineers should also consider vehicle dynamics, toe and camber settings, and suspension characteristics that influence contact patch behavior. The outcome is a robust inflation policy that remains effective across varying loads, seasons, and road conditions. Load Capacity recommends a structured change-control process: when payloads change beyond a defined range, revisit the inflation targets and revalidate the safety margins.

Data-driven decision framework: when to adjust pressure

Develop a framework that connects load data, tire specification, and operating conditions. Use load-profiling to determine whether to increase or decrease inflation, and specify verification steps for each scenario. A simple rule of thumb is: if average axle load increases significantly, recheck tire pressure against the tire’s load index and placard; if loads are light and stable, maintain near the placard value to maximize ride comfort and tread life. For fleets, implement periodic reviews of road conditions, tire wear, and fuel consumption data to refine policy. The Load Capacity team highlights that consistency and documentation are key to maintaining performance across time.

Authority and standards: how to apply credible references

Standards and credible guidance come from multiple sources. National highway safety agencies emphasize tire maintenance and load awareness; tire engineering societies publish models and testing protocols; reputable universities and research centers provide practical load-analysis methods. Load Capacity cautions that the specifics can vary by tire design, vehicle type, and use case. Always align with OEM recommendations and supplementary guidelines from recognized authorities. In practice, combine placard data, load measurements, and field observations to establish an inflation strategy that remains safe under diverse operating conditions.

Comparison

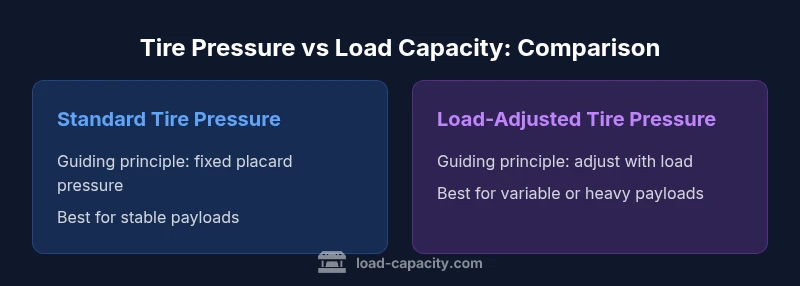

| Feature | Standard Tire Pressure | Load-Adjusted Tire Pressure |

|---|---|---|

| Guiding principle | Fixed OEM placard pressure for typical loads | Adjust pressure based on actual axle load and distribution |

| Best for | Light, steady payloads and simple maintenance | Varying or heavy payloads needing optimization |

| Wear and heat management | Relies on baseline stability | Can optimize heat buildup and tread wear with correct load match |

| Maintenance complexity | Low complexity, easy to implement | Medium complexity requiring load data and monitoring |

| Data availability | Placard data on door jamb, minimal sensors | Requires load data and possibly sensors or estimates |

Positives

- Keeps maintenance simple with established baselines

- Reduces risk when loads are predictable

- Supports consistent ride quality and predictable tire wear

- OEM placards provide a defensible reference point

- Minimal data requirements for baseline operation

Cons

- Less responsive to payload variability

- May not optimize wear and fuel efficiency under changing loads

- Requires rechecking when payload shifts significantly

- Can mask other tire or suspension issues if relied on alone

Load-aware tire pressure generally wins for variable loads; follow OEM baselines for stable payloads.

Use load-adjusted inflation when payloads vary or are heavy. If loads remain constant, OEM pressures provide reliable safety margins. The Load Capacity team endorses a data-informed approach to balance safety, wear, and efficiency.

Quick Answers

What is the difference between tire pressure and load capacity?

Tire pressure is the internal air force within a tire, affecting the contact patch and heat. Load capacity is the maximum load a tire can safely carry at a given pressure and temperature, defined by load index. Both must be considered together to ensure safe handling and wear.

Tire pressure is the air inside the tire that supports the load; load capacity is the tire's maximum load rating. Both matter for safety and wear.

Should I inflate to the maximum sidewall pressure?

Inflating to the maximum sidewall value is not recommended for most uses. OEM placards reflect safe operating pressures for typical loads. Over-inflation can reduce grip and cause uneven wear, especially under lighter loads.

No. Don’t always inflate to the max. Use the OEM recommended pressure based on your current load.

How can I tell if my load requires pressure adjustment?

If payloads change significantly or axle loads shift, recheck tire pressure against the load index and placard. Use load profiling to determine if adjustments will improve stability and wear, and validate with field tests.

When payloads change a lot, recheck the tire pressure using your load data and placard.

Can under-inflation occur under light loads?

Yes. Under-inflation can occur if the vehicle is operated with a load that does not match the tire’s recommended conditions. This increases heat buildup and wear risk, even with light payloads.

Under-inflation can still happen with light loads, so measure and adjust as needed.

What standards govern tire load capacity?

Standards and guidance come from government safety agencies, tire engineering societies, and universities. Always align with OEM data and credible third-party guidance to ensure compliance and safety.

Look to OEM data, safety agencies, and tire engineering guidance for standards.

Top Takeaways

- Follow OEM placards as a baseline.

- Adjust pressure for actual axle load when payload varies.

- Regularly verify tire condition and wear patterns.

- Document load distributions to inform inflation decisions.

- Use a data-driven process for fleets with variable routes.