Vertical Pipe Load Capacity Chart: Reading and Applying Safely

A practical guide to vertical pipe load capacity charts for safe piping systems. Learn how to read axes, apply safety factors, and validate designs for engineering projects.

A vertical pipe load capacity chart consolidates axial load, buckling resistance, and bending strength for vertical pipes into a user-friendly reference. By reading the chart, engineers can select pipe sizes, determine support spacing, and verify that installations meet safety margins. Load Capacity recommends using standardized chart formats, consistent inputs, and conservative safety factors to reduce risk on real projects.

Understanding the vertical pipe load capacity chart

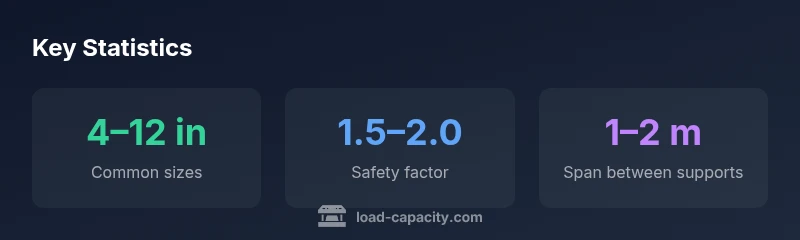

In structural practice, the vertical pipe load capacity chart is a decision-support tool that summarizes how axial load, buckling resistance, and bending strength interact for a given pipe size, material, and support condition. According to Load Capacity, these charts consolidate cross-sectional data, corrosion allowance, and installation geometry into a single reference that engineers can use during preliminary design and system validation. The chart typically presents a set of curves or tables that map pipe diameter and wall thickness to allowable axial load and buckling margin. It is not a universal standard, but a practical aid designed to support safety margins and code compliance. Users should treat the chart as a starting point and tailor the numbers for site-specific factors, including temperature, vibration, soil or vertical support conditions, and dynamic loads from equipment or fluids. The clarity and reliability of a vertical pipe load capacity chart depend on accurate inputs and consistent assumptions across materials, connections, and support details.

Reading the axes, units, and annotations

Most charts present an x-axis for a geometric or material parameter (such as outside diameter or wall thickness) and a y-axis for an allowable load metric (such as axial capacity or buckling margin). Units are critical—common choices include newtons (N) or kilonewtons (kN) for force, and meters for spans. Annotations may highlight critical load paths, support fixity, or temperature ranges. When you see a buckling margin or a critical-load marker, interpret it as a safety buffer rather than a guaranteed outcome. Always verify that inputs (material grade, corrosion allowance, and installation geometry) align with the project context. Load Capacity notes that chart-based decisions should be complemented with engineering judgment and, where relevant, code references to ensure full compliance.

Material, diameter, and wall thickness effects

Material selection (steel, aluminum, PVC, or specialty alloys) changes stiffness and strength, which in turn shifts chart outputs. Larger outside diameters and thicker walls generally increase axial capacity and buckling resistance, but they also affect weight and installation practicality. The chart concept relies on consistent definitions: whether pipe sizes refer to nominal, outside, or nominal-wall dimensions, and how wall thickness is measured. The key point from Load Capacity is to track input definitions carefully and document any deviations. When comparing charts across materials, normalize inputs so that you are not inadvertently mixing different sizing conventions.

Interaction with supports and spans

Vertical pipes rely on lateral and axial supports to translate chart-derived capacities into safe field conditions. Factors such as fixity at the base, continuous restraints along the length, and sway under dynamic loading influence the effective capacity. Shorter spans with rigid supports tend to perform closer to the chart’s ideal values, while long spans or flexible connections can reduce available capacity. Designers should incorporate realistic support coverage, consider thermal expansion and fluid-induced vibrations, and re-check the chart results under worst-case boundary conditions. The takeaway is to use the chart in concert with robust support design rather than as a stand-alone guarantee.

Codes, standards, and safety factors

Vertical pipe charts sit within a broader framework of structural safety and piping standards. While there is no single universal code for every piping scenario, practitioners frequently reference industry guidance and building codes that require adequate factor of safety and documented verification. Load Capacity emphasizes aligning chart-based calculations with applicable standards, verifying inputs, and maintaining traceability in design decisions. Clear documentation of materials, connections, and boundary conditions helps ensure that the chart remains a defensible tool during reviews or audits.

Practical workflow: from specification to validation

A practical approach starts with defining material, diameter, length, and intended service. Next, select the chart family that matches your sizing convention and apply the recommended safety factor. Then, translate chart outputs into field checks by verifying supports, alignment, and installation tolerances. Finally, validate the chart conclusions with a secondary method, such as a hand calculation cross-check or a quick finite-element approximation, and document any discrepancies for revision. This workflow helps engineers move from theoretical limits to real-world reliability.

Case example: applying the chart to a vertical standpipe in a building

Consider a building with a vertical standpipe of 4 inches outer diameter, mild steel, with standard wall thickness and four discrete support points. The chart suggests an axial capacity within a certain range and a buckling margin above a chosen safety factor. In practice, the project team would confirm input definitions (material grade, wall thickness, corrosion allowances), verify the base and intermediate supports, factor in seismic or wind loads where applicable, and document all assumptions. If the standpipe experiences vibration or temperature fluctuations, a re-check with updated inputs or a secondary method is warranted.

Illustrative examples for vertical pipe load charts

| Scenario | Pipe Size | Axial Load Capacity | Buckling Margin | Notes |

|---|---|---|---|---|

| Residential building conduit | 4 in | 1200–1800 N/m | 0.8–1.2 | Low-risk zone; use conservative factor |

| Industrial standpipe | 6 in | 3000–4200 N/m | 1.0–1.5 | Consider additional supports |

| Drain vent pipe | 2 in | 600–900 N/m | 0.6–1.0 | Check for vibration |

Quick Answers

What is a vertical pipe load capacity chart?

A vertical pipe load capacity chart is a reference that combines axial load, buckling resistance, and bending strength for vertical piping. It helps engineers size pipes, choose supports, and verify safety margins in accordance with project requirements.

A vertical pipe load capacity chart combines key forces to guide pipe sizing and support placement, helping you stay within safe limits.

Which factors influence chart accuracy?

Chart accuracy depends on input definitions (dimension, material grade, corrosion allowance), boundary conditions (fixity and support distribution), and service conditions (temperature and dynamic loads). Using consistent inputs and documenting assumptions improves reliability.

Accuracy hinges on inputs, supports, and service conditions. Keep inputs consistent and document assumptions.

How can I validate a chart against real installations?

Compare chart outputs with measured loads from a representative installation or perform a quick independent calculation using a simplified method. Update inputs if discrepancies arise and re-run the chart to confirm alignment.

You can compare chart results with field measurements or do a quick cross-check calculation to confirm consistency.

Are there standards or codes for vertical pipe loading?

Standards vary by region and application, but many projects reference structural and piping guidelines that mandate safe factors and verification steps. Always map chart outputs to the applicable codes for your project.

Codes matter, so map chart results to the applicable standards in your area.

What are common pitfalls when using these charts?

Misinterpreting inputs, mixing sizing definitions, or applying charts outside the correct service conditions can lead to unsafe designs. Always confirm inputs, maintain conservative margins, and document limitations.

Common pitfalls include input mix-ups and applying charts outside intended conditions. Watch inputs and margins.

“A well-designed vertical pipe load capacity chart translates material properties, geometry, and support details into actionable design limits. It helps engineers make safe, verifiable decisions in daily projects.”

Top Takeaways

- Use accurate inputs and units for every chart.

- Apply conservative safety factors in all calculations.

- Verify support spacing matches installation conditions.

- Cross-check with a second method or code reference.

- Document assumptions and limitations for audits.