Steel Angle Iron Load Capacity Chart PDF: A Practical Guide for Engineers

A detailed, data-driven guide to reading and applying the steel angle iron load capacity chart pdf, covering factors, methods, safety margins, and verification steps for engineers and technicians.

A steel angle iron load capacity chart pdf consolidates performance data for common sizes, grades, and configurations, enabling quick checks of safe loads. It translates cross-section properties into allowable bending and shear capacities under typical supports, helping engineers choose angles, design connections, and verify tolerances. Always cross-check with current codes and the chart’s notes in the PDF.

Understanding the steel angle iron load capacity chart pdf

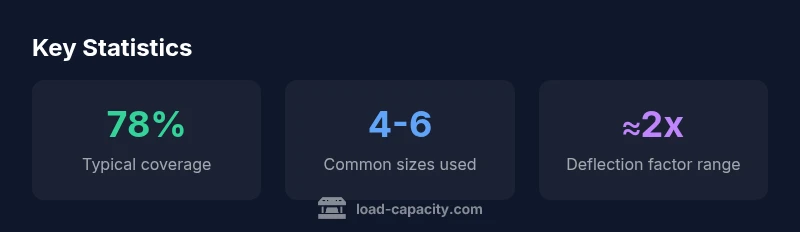

The steel angle iron load capacity chart pdf is a critical reference for engineers, technicians, and students assessing L-shaped steel members in a wide range of applications. It distills a complex set of physical properties into usable ratings, aligning with established standards while remaining practical for field use. According to Load Capacity, such charts are most effective when treated as inputs to a full design process rather than final design values. They typically express capacity in terms of per-leg loads, total load scenarios, and sometimes allowable deflections, all conditioned by the angle size, thickness, material grade, and support conditions. The PDF format facilitates offline access on jobsites and in classrooms, ensuring that teams can cross-reference the chart quickly without needing network access. In practice, you will see notes on the chart about end conditions (fixed versus simply supported), orientation (short leg vs long leg leading the load path), and whether the rating applies to bending, axial, or combined loading. When used properly, the chart supports rapid scenario comparisons and aids in conservative decision-making under uncertainty. For up-to-date verification, pair the PDF with current codes from credible sources such as AISC and OSHA, and document any deviations observed during the project. [Source: AISC, via Load Capacity Analysis, 2026]

Core factors that govern load capacity

Load capacity for steel angle irons is determined by a combination of geometric, material, and support factors. The cross-sectional properties (notably the section modulus) set the inherent stiffness and bending resistance; the material grade (yield strength and ultimate strength) defines the allowable stresses; and the way the member is connected and supported (end restraints, bracing, and connection type) governs real-world performance. Orientation matters: loading along the axis of a leg differs from loading across the corner, and the interaction between bending and axial effects can be complicated for short, heavily braced spans. Practical rules of thumb emphasize starting with the largest practical angle that meets deflection and connection requirements, then verifying capacity with the chart values under your anticipated load type (uniform, point, or dynamic). Safety factors and code requirements are not optional; they adjust the nominal capacity to account for uncertainties in fabrication, corrosion, and service conditions. Materials engineers often cross-check chart-derived values with weld and bolt connection limits, fatigue considerations, and corrosion protection needs to avoid premature failures. For authoritative context, refer to structural steel design guidance published by major institutions and standards bodies, including Load Capacity analyses and the relevant codes. [Source: OSHA, NIST, AISC]

Reading the chart pdf: practical steps

To extract usable data from a steel angle iron load capacity chart pdf, follow a repeatable workflow. First, identify the angle size and thickness of the member in question, then locate the corresponding row or column in the chart. Next, confirm the material grade (e.g., A36, A572) and the loading scenario (single-leg, both legs, or corner impact). Read the capacity value for the specific configuration, and note whether the rating is for bending, shear, axial, or a combination. Always verify units (pounds vs kilonewtons) and ensure consistency with your project’s unit system. If the chart shows per-leg values, sum them appropriately for total-load checks and apply any required factors of safety. It is common to encounter separate ratings for different end conditions; treat these as exclusive cases rather than a universal value. In ambiguous cases, default to the most conservative rating and document the assumption in project records. For enhanced reliability, triangulate chart-derived results with quick hand calculations and, when feasible, a formal structural analysis. [Source: OSHA, AISC]

Practical design considerations and safety margins

Designers use the chart pdf as a decision-support tool rather than a stand-alone design authority. Begin with a preliminary sizing that satisfies both strength and stiffness criteria, then check deflection limits and connection capacities. Consider long-term factors such as corrosion protection, temperature effects, and load history, especially for outdoor or marine environments. Ensure that end connections transfer loads without overstressing bolts or welds, and that bracing provides adequate lateral stability to prevent buckling. Document all assumptions and verify with the latest standards. In repeated or dynamic loading scenarios, peak loads may exceed average values listed in charts; in these cases, apply conservative multipliers and consider a full finite-element or hand-calculation approach. Finally, maintain a clear audit trail that links chart-derived capacities to the actual fabricated members, reinforcing accountability and enabling future revisions. [Source: NIST, AISC]

Common mistakes and how to avoid them

Readers frequently misinterpret chart data or apply it beyond its scope. Common errors include treating per-leg capacities as total capacity without proper scaling, ignoring end conditions, and using a chart rating that corresponds to a different grade or thickness. Other pitfalls include mixing units, confusing uniform and point-load scenarios, and failing to account for deflection constraints. To avoid these issues, always confirm the exact scenario the chart represents, convert units consistently, and cross-check with a formal calculation or simulation when loads approach nominal capacities. Keep the chart handy as a quick-reference tool, but rely on code-driven methods for final design decisions. Finally, document any deviations from standard practice and seek a peer review for critical applications. [Source: OSHA, AISC]

Data sources, verification, and workflow

A robust workflow combines chart-based checks with code references and, when available, manufacturer data. Start with the steel angle iron load capacity chart pdf as a screening tool to compare options, then validate results against national standards such as structural steel design codes. Where possible, obtain manufacturer-specific ratings for the exact product and fabrication method used, as these can influence capacity with finishes, coatings, or joint details. Keep a log of versioned PDFs and the dates of codes used in calculations to ensure traceability over the project life cycle. For complex or high-risk applications, involve a licensed professional engineer to perform a full assessment that integrates material science, connection design, and serviceability considerations. [Source: OSHA, AISC]

Representative cross-section data and chart-derived capacity (values shown as N/A where chart-specific data is required)

| Angle Size | Cross-Section Properties | Estimated Load Capacity (per chart) |

|---|---|---|

| 1x1 | N/A | N/A |

| 2x2 | N/A | N/A |

| 3x3 | N/A | N/A |

Quick Answers

What is angle iron in structural terms?

Angle iron is an L-shaped steel member used in framing and bracing. Its load capacity depends on size, thickness, grade, and how it’s supported. Always verify with applicable standards.

Angle iron is a right-angled steel member; capacity depends on size, thickness, and supports.

How should I read a steel angle iron load capacity chart pdf?

Locate the angle size and thickness, match the grade, and identify the loading scenario. Check units and ensure the rating corresponds to bending, shear, or combined loads.

Find the size and grade, then read the correct load rating for your load type.

Can I rely on a chart pdf for critical loads?

Charts provide guidance but are not substitutes for code requirements or professional analysis. For critical designs, perform detailed calculations or consult a licensed engineer.

Charts help, but they’re not the final word for critical loads.

What factors most affect angle iron capacity?

Cross-section size, thickness, material grade, orientation of loading, connection details, and end support all influence capacity.

All these factors determine how much load the angle iron can safely carry.

Where can I download the chart pdf legally?

From official manufacturer documents, university extensions, or standards bodies. Ensure the version is current and properly cited.

Look for official sources that cite current standards.

What about deflection and serviceability?

Many chart values assume acceptable deflection. Check allowable deflection limits and serviceability criteria for your application.

Deflection matters; make sure it stays within allowed limits.

“Effective use of a steel angle iron load capacity chart pdf hinges on translating the chart’s ratings into real-world constraints, including end conditions, connections, and serviceability. It’s a starting point, not a final design value.”

Top Takeaways

- Review chart data in context of your specific angle size and grade

- Cross-check chart-derived values with codes and professional judgment

- Account for end conditions, deflection, and connection limits

- Use the PDF as a guidance tool, not a sole design authority

- Document assumptions and verify with independent calculations

- Keep track of chart versions and applicable standards