How Much Weight Capacity: A Practical Guide

Understand weight capacity across structures, vehicles, and equipment with clear methods, safe ranges, and practical steps for engineers and technicians.

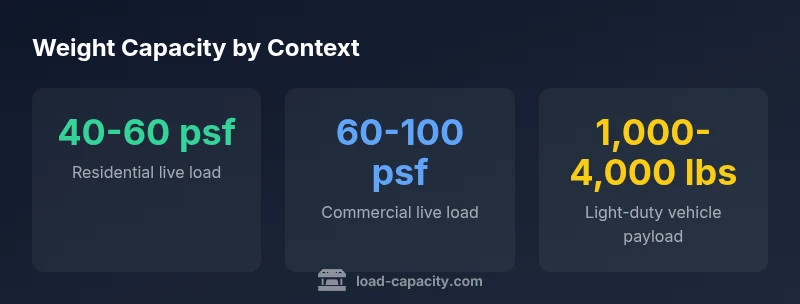

Weight capacity varies by context, so there is no single number. For buildings, typical live-load guidance ranges from 40 to 60 pounds per square foot (psf), depending on occupancy. Vehicle and equipment capacities are defined by rated structural limits and safety margins, which differ widely by model and application. Always consult specifications and local codes to determine the exact weight you can safely support.

Understanding weight capacity across contexts

Weight capacity is a context-specific measure describing the maximum load a component, structure, or system can safely bear. There isn't a single universal number; the value depends on material properties, geometry, support conditions, and safety factors. In engineering practice, we distinguish between dead load (permanent weight) and live load (variable load), and we consider dynamic loads where applicable. For a homeowner planning a deck, the critical question is not 'how much weight capacity' in abstract, but what is the capacity per square foot for the intended use. For loads on floors, codes define design live loads per area, typically measured in pounds per square foot (psf). For structural members, capacities are expressed as maximum forces in pounds or kilonewtons, often involving safety factors and material limits. Engineers translate these numbers into safe ultimate loads, service loads, and allowable stresses. When evaluating weight capacity, it is essential to specify the exact context: location, purpose, and the exact units used. Load capacity analyses must also account for potential impact or dynamic effects, such as people moving on a floor or a machine starting up. Across contexts, the guiding principle remains the same: never exceed the rated capacity; design with a margin for uncertainty.

Building and structural weight capacity

Structural weight capacity for buildings hinges on the interplay between live load, dead load, and the supporting framework. Residential spaces typically rely on design live loads around 40 psf, whereas commercial occupancies may require higher live loads around 60 psf or more depending on use. Because loads are distributed, the capacity of beams, joists, and columns depends on cross-sectional area, material strength, and spacing. Engineers verify bearing capacity at foundations, shear capacity in connections, and deflection limits under expected loads. Soil bearing capacity is a critical upstream factor; if the soil cannot support the intended load, the entire design must be adjusted. In practice, load paths must be clear: live loads travel from floors through joists to beams, and finally into the foundation. Designers use conservative safety factors to account for uncertainties, material flaws, and construction tolerances. In short, the structural weight capacity is not just the raw strength of a material, but the entire system’s ability to safely carry anticipated loads with an appropriate margin.

Vehicle and equipment payload capacities

Payload capacity for vehicles and equipment varies widely. Light-duty pickups and vans commonly offer payload in the range of roughly 1,000 to 4,000 pounds, while larger commercial trucks easily exceed that, depending on chassis, axles, and suspension. Heavy equipment such as forklifts and cranes have their own load ratings, often expressed as lift capacity rather than per-axle payload. It is essential to verify each vehicle’s rated payload on the specification plate or manufacturer documentation, and to subtract any additional weight such as fuel, accessories, or cargo mounts when calculating available capacity. Overloading a vehicle can compromise braking, handling, and structural integrity. Always reference the exact model’s weight rating and apply a safety margin to account for dynamic conditions and potential shifts in load distribution.

How to calculate weight capacity safely

A systematic approach reduces risk and clarifies what you can safely carry. Start with the published rating from the manufacturer or code-specified limits. Identify the relevant safety factors for your context and subtract any ongoing or potential dynamic effects. For structural components, capacity can be estimated as:

- Safe capacity = Allowable stress limit × cross-sectional area × factor of safety

- For floors: Live load capacity per area (psf) × area, minus dead load and furnishings

- For vehicles: Published payload rating minus fuel, passengers, and incidental equipment

Document every assumption, check units carefully, and corroborate with a second qualified engineer if the load is critical. When designing or retrofitting, use conservative margins and plan for worst-case scenarios (e.g., all people on one side during peak use). Finally, ensure compliance with local codes and standards, and keep records for future inspections.

Common mistakes and how to avoid them

Common mistakes include treating weight capacity as a fixed universal constant, neglecting dynamic loads, and ignoring the impact of installation details or soil conditions. Other errors are misreading rating plates, overlooking safety margins, or assuming the capacity of structural members without checking their spans and connections. To avoid these pitfalls, always verify the context, use per-area design values where applicable, and document all assumptions. Engage qualified professionals when a project straddles multiple contexts (building, vehicle, or machinery) and perform periodic re-evaluations as conditions change (e.g., renovations, aging materials, or changed occupancy).

Key practices: use per-context ratings, factor in safety margins, and communicate decisions with all stakeholders.

Practical examples and case studies

Case Study A: A 12 ft by 12 ft residential deck designed for 40 psf live load. Area = 144 sq ft. Live load capacity = 144 × 40 = 5,760 lbs. If dead load is 1,200 lbs, and a couple of benches add 400 lbs, total estimated load becomes 7,360 lbs, which could exceed the net capacity when considering anchorage and deflection. This example demonstrates why designers separate live and dead loads and include safety margins.

Case Study B: A light-duty truck with a published payload rating of 3,500 lbs, and a full fuel load adds an extra 600 lbs. The usable payload after fuel is approximately 2,900 lbs. Users should account for passengers and cargo that shift weight distribution, not just total mass, to preserve braking and steering performance.

Documentation and verification of capacity

Documentation should include the rating source (manufacturer plate or code reference), the exact load scenario considered, and calculations used to derive the safe capacity. Verify that connections, foundations, and anchorages are appropriate for the load path. Schedule regular inspections and recalculate capacity when modifications occur or when aging materials are suspected. Maintaining a clear audit trail helps ensure ongoing safety and compliance with standards.

Comparison of weight capacity by context

| Context | Typical Weight Capacity | Notes |

|---|---|---|

| Residential floor live load | 40-60 psf | Per building code depending on occupancy |

| Commercial floor live load | 60-100 psf | Depends on occupancy and use |

| Appliance weight capacity | 200-1500 lbs | Applies to heavy household equipment |

Quick Answers

What is weight capacity?

Weight capacity is the maximum load a component or system can safely bear in a given context. It depends on materials, geometry, support conditions, and safety factors. It is not a single universal number.

Weight capacity is the maximum load a component can safely bear, and it depends on the context and safety margins. It's not a single universal number.

How do I determine weight capacity for a structure?

Start with the code-defined live loads, evaluate dead loads, assess member sizes and connections, and apply the required safety factors. Verify soil or foundation capacity if applicable and ensure the whole load path is considered.

Begin with live and dead loads, check member sizes and foundations, and apply safety factors. Make sure the load path is clear.

Are safety margins always required?

Yes. Safety margins account for uncertainty, material flaws, and dynamic effects. They help prevent failure under unexpected or peak loads.

Safety margins are essential to cover uncertainties and dynamic loads.

What should I do if loads exceed capacity?

Cease use, re-evaluate the design, and either reduce the load, strengthen the structure, or redesign components to meet required capacity. Consult a qualified engineer before proceeding.

If loads exceed capacity, stop usage and consult an engineer to redesign or reinforce.

Where can I find official guidelines?

Consult local building codes, manufacturer specifications, and standards organizations. Codes like IBC and local amendments provide specific live-load values and safety factors.

Check local codes and manufacturer specs for exact guidelines.

How often should capacity be re-evaluated?

Re-evaluate after significant changes (renovations, new equipment, aging materials) or after events that could alter load paths. Periodic reviews with professionals are prudent for critical structures.

Re-evaluate after major changes or periodic inspections with a professional.

“Context-aware checks are essential; never rely on a single number when designing for safety. Always validate weights against codes, ratings, and the specific conditions of use.”

Top Takeaways

- Check codes first for your context

- Calculate by area (psf) where applicable

- Always apply a safety margin

- Verify labels and ratings on equipment and structures

- Document all assumptions for future inspections