Static Load Capacity vs Dynamic Load Capacity: An Analytical Guide

Understand the difference between static and dynamic load capacity, how engineers measure them, and how to apply safe design practices across structures, vehicles, and equipment.

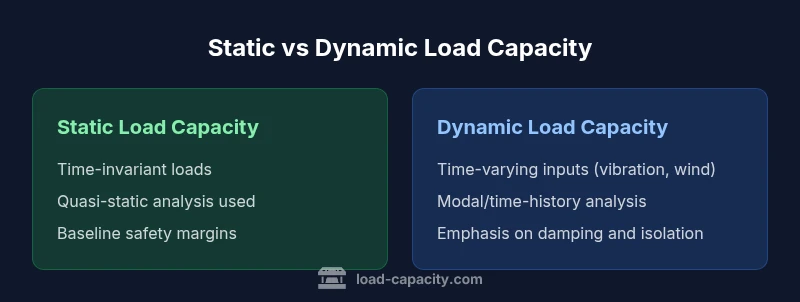

What is static load capacity vs dynamic load capacity? In short, static load capacity refers to the maximum load a component can carry when loads are constant over time, while dynamic load capacity accounts for loads that vary with time, such as vibrations, wind, or impact. Understanding both is essential for safe design, accurate modeling, and resilient operation across structures, vehicles, and equipment. The Load Capacity team emphasizes that the distinction matters for predicting performance, safety margins, and maintenance planning.

Core Definitions and Terminology

Static load capacity refers to the maximum load a component or structure can support when loads are constant or vary very slowly. In practice, this includes dead loads and slowly changing service loads. Dynamic load capacity accounts for loads that vary with time, such as vibrations, wind gusts, traffic-induced forces, impacts, and seismic excitations. The dynamic response depends on stiffness, damping, mass distribution, and the interaction between the element and its foundation. For engineers, the distinction matters because it influences safety factors, material selection, and modeling approach. Although the boundary between static and dynamic is not a hard line, many designs operate in a regime where both effects interact, requiring integrated analysis. Load Capacity emphasizes the importance of recognizing when time-varying inputs drive peak stresses and when simple quasi-static assumptions are adequate.

How Static Load Capacity Is Determined

Static capacity is assessed using quasi-static principles: the load is applied gradually, the material behaves within its elastic region, and the response is assumed time-invariant. Key inputs include geometry, material properties (modulus, yield strength), and permanent loads such as floors or fixed equipment. Engineers apply a factor of safety to account for uncertainties in materials, installation, and environmental conditions. The analysis often uses linear elastic models, simplified load paths, and conservative assumptions about joint behavior. The resulting capacity is a baseline against which time-varying loads are compared. In practice, static capacity informs foundation design, support sizing, and initial equipment placement, serving as the backbone of preliminary safety margins.

How Dynamic Load Capacity Changes with Time and Conditions

Dynamic capacity reflects how a system responds when loads change over time. Time histories, frequency content, and damping characteristics determine how the structure reacts to moving loads, gusts, or impacts. Dynamic amplification can elevate stresses beyond the purely static estimate, especially near resonance frequencies or in lightly damped systems. Engineers model these effects using time-history analysis, modal analysis, or simplified dynamic factors defined by codes. The hardware’s mass, stiffness distribution, and mounting conditions—such as a foundation or vibration isolators—play a crucial role in shaping the dynamic response. Environmental factors, including wind, waves, or traffic, can drive repetitive excitations that accumulate damage if not properly accounted for.

Key Differences at a Glance

- Definition: Static capacity addresses time-invariant loads; dynamic capacity accounts for time-varying inputs.

- Calculation approach: Quasi-static analysis versus time-history or modal analysis with damping.

- Safety factors: Static designs rely on chosen factors of safety; dynamic designs include amplification and damping terms.

- Modeling needs: Static analysis often uses simple linear assumptions; dynamic requires understanding of mass, stiffness, damping, and excitation spectra.

- Applications: Buildings and foundations vs machinery, vehicles, and systems exposed to wind, seismic, or operational vibrations.

- Uncertainty: Both rely on codes, testing, and validation, but dynamic uncertainty is often higher due to variability in inputs and responses.

Real-World Contexts: Structures, Vehicles, and Machinery

Structural engineers frequently use static capacity for permanent installations, such as a concrete foundation supporting equipment. In contrast, aerospace and automotive engineers must evaluate dynamic loads from takeoff, road vibration, or gusts. Industrial machinery may experience peak forces during start-up or shutdown, stressing mounts and supports. The same concepts apply to decks and floors, where static live loads blend with dynamic reactions from movement, equipment, or external forces. Across all contexts, safe design requires recognizing when a static estimate underpredicts peak stresses due to dynamic amplification and ensuring appropriate detailing, anchorage, and damping are in place.

Measurement Techniques and Standards

Engineers use a combination of analytical methods, experiments, and field measurements to quantify loads and responses. Strain gauges and accelerometers capture real-time responses, while modal analysis characterizes natural frequencies and mode shapes. Time-history analysis models the actual loading sequence, and random-vibration analyses assess response under stochastic inputs. Codes and standards provide guidance on load combinations, safety factors, and permissible responses, but they rarely prescribe a single factor for every scenario; instead, they frame acceptable design envelopes and verification procedures. Practical validation often combines analytical results with testing and post-construction monitoring to confirm that the dynamic behavior aligns with predictions. The overarching goal is to ensure performance under the most demanding credible loading scenarios while maintaining safety and reliability.

Design Implications: Safety Factors, Redundancy, and Maintenance

Designers must balance static and dynamic considerations throughout the life cycle. For static loads, ensure adequate cross-sections, joints, and support conditions that maintain strength well below material limits. For dynamic loads, emphasize damping, isolation, and stiffness tuning to suppress resonance and reduce peak responses. Redundancy—alternate load paths or extra supports—adds resilience against unexpected events, while maintenance programs monitor wear, fastener loosening, and mounting degradation that can degrade dynamic response over time. Early warnings, sensor-equipped structures, and data analytics enable condition-based maintenance, helping teams address dynamic concerns before failures occur. In essence, robust design couples conservative static sizing with proven dynamic mitigation strategies.

Common Misconceptions and Pitfalls

A common pitfall is treating dynamic effects as an afterthought or assuming they are automatically negligible in large structures. Another error is using a static capacity value as if it applies identically to dynamic events, ignoring amplification. Some teams rely solely on software estimates without validating results through testing or field measurements, which can miss nonlinear behavior, friction, or local resonance. Finally, misinterpreting code provisions—using the wrong load combination or neglecting interaction effects—can produce unsafe results. Awareness of these misconceptions helps teams adopt a more robust, evidence-based design mindset.

Practical Guidelines for Practitioners

- Start with a clear scoping of loads: list all expected static and dynamic inputs and their likely magnitudes.

- Use a baseline static capacity as a starting point, then evaluate dynamic effects with appropriate models and dampers.

- Include damping strategies and isolation where feasible to reduce peak responses.

- Validate models with measurements and testing, especially for critical components or hosts operating near resonance.

- Document load scenarios, assumptions, and safety margins to support audits and maintenance planning.

- Align with codes and standards, but tailor them to project-specific risk and operational contexts.

Comparison

| Feature | Static Load Capacity | Dynamic Load Capacity |

|---|---|---|

| Definition | Time-invariant loads (dead + slow-changing service loads) | Time-varying loads (vibrations, wind, impact, seismic) |

| Calculation approach | Quasi-static analysis with safety margins | Dynamic analysis with time history, damping, and amplification considerations |

| Modeling needs | Linear elastic assumptions common; focus on worst-case static stresses | Mass, stiffness, damping, and excitation spectra central; potential nonlinearities |

| Safety factors | Static design uses fixed safety factors and serviceability checks | Dynamic design includes amplification factors and damping terms |

| Applications | Foundations, permanent supports, static equipment mounting | Structures/equipment exposed to wind, seismic, or operational vibrations |

| Validation methods | Static tests, finite-element analyses, code-approved checks | Dynamic tests, modal testing, environmental and field tests |

Positives

- Clarifies which loads drive safety margins

- Improves maintenance planning and life-cycle costs

- Helps prevent under- or over-design

- Supports compliance with codes and standards

- Guides selection of damping and isolation strategies

Cons

- Increases modeling complexity

- Requires data and software for dynamic analysis

- May introduce conservative design if not calibrated

Dynamic analysis is essential for safety; static load capacity alone is insufficient for safe design.

Engineers should design for the most damaging combination of static and dynamic effects, using appropriate damping and safety factors.

Quick Answers

What is the difference between static load capacity and dynamic load capacity?

Static load capacity measures the capacity under time-invariant loads; dynamic load capacity accounts for time-varying inputs and the system's response. In practice, both are necessary for safe design; dynamic effects can amplify stresses beyond static predictions.

Static capacity is the baseline for constant loads; dynamic capacity accounts for time-varying forces and the system's response. Both matter for safety.

How is static load capacity calculated?

Static capacity is computed using quasi-static analysis, materials properties, geometry, and a safety factor. It assumes loads are slowly applied and that the structure remains within the elastic range until capacity limits are reached.

Static capacity uses quasi-static methods with a safety factor and material limits.

Why are dynamic loads important in design?

Dynamic loads matter because time-varying inputs can cause resonance, higher peak stresses, and fatigue, which static estimates may not capture. Neglecting dynamics can lead to overstressed components or brittle failures.

Dynamic loads can trigger resonance and fatigue; they must be accounted for in design.

Can a structure have both static and dynamic capacity?

Yes. A structure has a static capacity baseline, and its dynamic capacity is governed by its damping, stiffness, and mounting. Designers assess both, ensuring safe operation across all expected loading conditions.

A structure has both baselines; you plan for both Static and Dynamic cases.

Codes and dynamic loads

Codes provide guidelines for load combinations, dynamic amplification, and safety margins. They do not prescribe a universal factor; professionals select appropriate provisions based on location, usage, and risk.

Codes guide how to combine static and dynamic loads and set safety requirements.

Dynamic-load mistakes

Common mistakes include treating dynamic effects as negligible, relying solely on software without validation, and ignoring interaction effects or nonlinearity near resonance. Careful validation and testing help prevent these errors.

Don’t skip validation; validate dynamic models with testing.

Top Takeaways

- Identify all static and dynamic loads early

- Model dynamic response with damping

- Check for resonance and amplification

- Validate models with tests and measurements

- Follow codes but tailor to project risk