What to Consider When Calculating Ladder Load Capacity

A comprehensive, engineer-friendly guide to calculating ladder load capacity. Learn factors, methods, and safety steps to assess static and dynamic loads for safer height work.

Goal: Determine the ladder's safe load capacity for a given task. You must consider user weight, carried tools, dynamic forces from climbing and reaching, ladder type and rating, base support and footing, and environmental factors. Always apply a safety factor and verify against manufacturer ratings. This quick check helps engineers, technicians, and supervisors decide if a task is safe or if equipment should be upgraded.

Why ladder load capacity matters for safety and compliance

According to Load Capacity, properly calculating ladder load capacity is essential for worker safety, preventing equipment failures, and maintaining regulatory compliance. When you accurately assess the load a ladder can bear, you reduce the risk of tipping, rung failure, and loss of task control. In many workplaces, documented calculations support risk assessments and training programs, helping teams justify ladder choices for specific tasks. A disciplined approach also minimizes downtime caused by weather delays or equipment replacement. The Load Capacity team emphasizes that a clear, auditable method builds confidence among technicians, supervisors, and safety officers alike.

In practice, load capacity isn’t a single number on a label. It’s a function of how the ladder will be used, who will use it, and what loads the work process creates. By documenting assumptions, you create a repeatable process that can be reviewed during audits or safety reviews. The main goal is to ensure that every task at height can be completed without exceeding the ladder’s rated capacity, while still allowing for productive work tempo and tool access.

Ladder types and their load ratings

Ladders come in several materials and configurations, including aluminum, fiberglass, wood, extension, and step ladders. Each type has a rating system that communicates the maximum safe working load under standard conditions. Labels typically specify a rating range, often expressed in pounds or kilograms, and may indicate whether the ladder is designed for specific environments (electrical insulation, for example). While the numbers on labels are important, the true load capacity also depends on how the ladder is set up, how far you reach, and whether you are working on uneven ground. Understanding the rating language helps engineers translate a label into safe work plans and task allocations. Load Capacity’s guidance stresses that a ladder’s rating is not a target to be pushed; it’s a boundary that informs safe practice.

Core components of the calculation

A robust ladder load calculation considers several interacting factors. Start with the static load: the individual’s weight plus any tools, equipment, and materials held or carried. Then account for dynamic loads created during ascent, descent, and reaching movements, which can temporarily amplify the force on rungs and rails. The ladder type and its rating determine the upper limit, while base support, footing, and surface conditions influence stability. Finally, environmental factors such as wind, vibration, or temperature can alter performance, so they should be included in the scenario description. A comprehensive approach combines these elements into a single load envelope that must stay under the ladder’s rated capacity.

Base stability, footing, and surface preparation

Stability starts at the ground. Ensure the ladder feet have clean, dry contact with a firm surface and that the ladder is positioned to prevent side-to-side movement. Use levelers or anti-slip pads where appropriate, and verify that the surface can support the combined load without shifting. For uneven terrain, consider shimming or selecting a ladder with adjustable feet. Proper base preparation reduces the chance of tip-over and helps maintain the intended load path through the rails and rungs under load.

Environmental and usage factors that influence capacity

Environment shapes the safe operating envelope. Wind gusts, vibrations from nearby machinery, and temperature changes can affect material properties and the user’s balance. When working outside, factor in wind-induced loading and possible contact with objects that add side forces. Inside, ensure there’s sufficient clearance for the user to climb without bumping nearby equipment. A well-documented task description that captures room conditions, weather, and access routes supports safe decisions and clear handoffs between crew members.

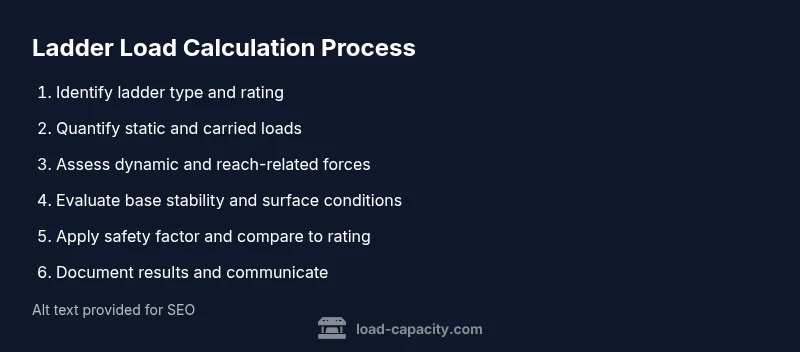

Step-by-step calculation approach (high-level)

A methodical calculation approach begins with gathering task details, then building a load budget. List the user’s weight and any carried tools, add a placeholder for dynamic loading due to movement, and apply a qualitative safety factor based on risk. Translate this into a comparison against the ladder’s labeled capacity, while checking for any manufacturer-specific guidelines. The final step is to document the results, reproduce the calculation later if needed, and decide whether to proceed, adjust, or choose a different ladder. This approach blends engineering rigor with practical field checks, helping teams make informed decisions.

Safety, documentation, and compliance considerations

Documentation reinforces good practice. Record the ladder type and rating, exact task description, environmental conditions, footing state, and all assumptions used in the calculation. If a discrepancy arises between expected and actual performance, review the calculation, inspect the ladder, and verify that the task aligns with safety policies. Regular ladder inspections and training reinforce safe behavior, while auditable records support regulatory requirements and workplace learning initiatives.

Practical examples and common scenarios (non-product-specific)

Consider scenarios where a worker carries a small set of hand tools while climbing to replace a component or perform routine maintenance. In such cases, evaluate the total potential load at typical work positions and ensure it stays within the ladder’s capacity under both static and dynamic conditions. When two or more workers share a ladder, additional coordination is necessary to ensure the combined load does not exceed what the ladder can safely handle. The goal is consistency: apply the same calculation method for every task, so safety margins remain predictable across the team.

Next steps: turning calculations into a usable checklist

Finish by converting the calculation results into a practical checklist that crews can use at the job site. Include steps to verify ladder type, confirm rating, measure reach and stance, inspect footing, test stability, and review environmental factors. A ready-to-use checklist reduces cognitive load during work and supports safer completion of height-related tasks.

Tools & Materials

- Tape measure(For measuring reach, stance width, and rung spacing during setup.)

- Ladder rating label and manufacturer manual(Have the exact rating and any environment-specific notes handy.)

- Calculator or spreadsheet(To compute static and dynamic loads and apply the safety factor.)

- Pen and notebook(Document assumptions, results, and any deviations for audits.)

- Level or angle gauge(Optional for confirming proper ladder angle when using extension ladders.)

- Personal protective equipment (PPE)(Gloves, eye protection as dictated by task and environment.)

Steps

Estimated time: 60-90 minutes

- 1

Identify ladder type and rating

Begin by recording the ladder material, model family, and the labeled rating. This sets the baseline capacity and helps interpret any environmental caveats from the manual. Cross-check the label against the site task to ensure the ladder is appropriate for use.

Tip: If the label is unreadable, contact the manufacturer or replace the ladder. - 2

Quantify the static and carried loads

Estimate the weight of the worker and any tools or materials carried at the moment of ascent. Sum these values to form the static load. This value represents the baseline that must be supported without considering dynamic effects.

Tip: Be conservative and assume the maximum possible weight you might carry during the task. - 3

Assess dynamic and reach-related forces

Consider how movement, reaching, and twisting could increase forces on rungs. Do not rely on a straight-line load; account for typical operational poses and pauses to gauge peak loads.

Tip: Dynamic loads can be several times the static load in critical moments. - 4

Evaluate base stability and surface conditions

Inspect the ground surface and ladder feet. Remove debris, ensure a level stance, and use anti-slip aids if needed. Instability here can magnify the impact of any excess load.

Tip: Stability is as important as load capacity in preventing tip-overs. - 5

Apply a safety factor and compare with rating

Choose a safety factor appropriate for the risk level (e.g., moderate risk tasks use a moderate factor). Compare the resulting required load to the ladder’s rated capacity. If the required load exceeds the rating, adjust the plan.

Tip: Document the factor used and rationale in the task record. - 6

Document and communicate results

Record all inputs, calculations, assumptions, and decisions. Share the outcome with the crew and safety officer, so everyone understands the justification for ladder choice.

Tip: Maintain records for audits and future task planning. - 7

Decide on next steps if capacity is exceeded

If the calculation shows the load exceeds the rating, identify alternatives—use a lighter tool setup, carabiners for load distribution, or switch to a higher-capacity ladder.

Tip: Improving load distribution can often resolve capacity issues without ladder replacement. - 8

Review after task and update procedures

After completion, review the calculation’s accuracy, update any guidelines, and adjust future task plans to reflect lessons learned.

Tip: Continuous improvement reduces risk over time.

Quick Answers

How do I determine the safe load on a ladder?

Begin with the user’s weight and any carried tools to form the static load. Add a qualitative dynamic load factor for movement and reaching. Compare the total against the ladder’s rating, applying a safety factor as needed. Document the inputs and results.

Start with weight plus tools, add an energy factor for movement, then compare to the ladder rating and note the safety margin.

How does dynamic loading affect ladder load capacity?

Dynamic loading accounts for moments of acceleration, deceleration, and shifting loads as a person climbs or reaches. It can significantly increase the peak load on rungs and rails beyond the static load, so it must be included in any calculation.

Dynamic loads happen during movement and reaching and can push the ladder beyond its static limit.

What is the difference between rating and capacity?

The rating on a ladder indicates the maximum safe load under standard conditions. Capacity is the practical limit you derive from your task context, including dynamic effects and environmental factors. Do not assume they are identical without validation.

Ratings tell you the ceiling; your task context determines if you stay under it.

Should environmental factors alter my calculation?

Yes. Wind, vibration, temperature, and surface conditions can change load behavior and stability. Incorporate these factors into your task description and adjust your margin accordingly.

Environment matters—the factors can change how load behaves and how stable the setup is.

Can multiple workers share a ladder safely?

If more than one person uses a ladder, re-evaluate loads with combined weight and movements. Ensure the rating covers the aggregate static and dynamic loads and that coordination minimizes peak loads.

Two people on one ladder change the load picture; recalculate for the combined effort.

What should I do if the calculated load exceeds the ladder rating?

Do not proceed with that ladder. Either distribute the load differently, reduce carried weight, or switch to a higher-capacity ladder. Reassess all calculations and document the rationale.

If it won’t fit, switch plans rather than push the ladder past its limit.

Watch Video

Top Takeaways

- Follow a structured ladder load calculation process

- Incorporate static, dynamic, and environmental factors

- Always verify against the ladder rating and add a safety margin

- Document assumptions and outcomes for audits

- If in doubt, choose a higher-capacity ladder or alternative access