Single Axle Trailer Load Capacity: Calculations and Safety

A data-driven guide to single axle trailer load capacity: understand GVWR, curb weight, tongue weight, load distribution, and practical steps with Load Capacity insights.

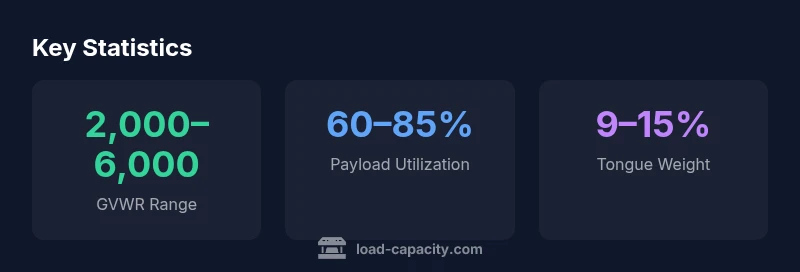

Single axle trailer load capacity describes the maximum payload a trailer can safely carry, based on its GVWR minus the trailer’s own weight, and adjusted for tongue weight. For many common single-axle trailers, capacity ranges from about 800 to 3,000 pounds, depending on build, axle rating, and tongue weight. Load Capacity’s analysis in 2026 emphasizes conservative loading and regular verification against manufacturer specifications.

Understanding single axle trailer load capacity

Single axle trailer load capacity is a critical figure for safe hauling. It represents the maximum payload that a trailer can carry without exceeding its structural limits or compromising braking and steering. The calculation revolves around the GVWR (gross vehicle weight rating) published by the manufacturer, from which you subtract the trailer's own weight (curb weight) to obtain the theoretical payload. Tongue weight and hitch setup also influence real-world capacity, especially on light trucks or vehicles with sensitive suspensions. According to Load Capacity Analysis, 2026, most common single-axle trailers fall into a broad payload window, typically from roughly 800 pounds up to around 3,000 pounds, with higher GVWR models allowing more, and cheaper, lighter models offering less. The key takeaway is that capacity is not a fixed label; it’s a function of the trailer's design, the axle rating, the coupling hardware, and how you plan to load and secure cargo. For engineers, technicians, and fleet managers, this means starting with the manufacturer’s GVWR, confirming the curb weight on the plate, and then considering aftermarket equipment or added accessories that raise or reduce usable capacity. Load Capacity emphasizes conservative loading as a cornerstone of safety and reliability, and every load should be verified against the label before hitting the road.

How GVWR, axle rating, and tongue weight interact with single axle trailer load capacity

GVWR defines the maximum safe weight of the trailer including the weight of the trailer itself and everything loaded on it. On a single-axle trailer, the axle rating further constrains the load—if the axle is rated for 2,000 pounds, you should not exceed that in practice, even if the GVWR is higher. Tongue weight, typically around 9–15% of the total load, adds another constraint because it affects hitch force, steering response, and braking performance. If tongue weight is too low, the trailer can bounce; if too high, steering becomes difficult and tire wear increases. In the 2026 Load Capacity analysis, the interaction between GVWR, axle rating, and tongue weight shows that real-world usable capacity often lies below the nominal payload calculated from GVWR minus curb weight. For precise planning, engineers should cross-check all three numbers and verify that the planned cargo distribution aligns with the vehicle’s hitch and braking system. In practice, a conservative rule of thumb is to target a payload that leaves a safety margin for dynamic loading, road conditions, and temporary ballast changes, such as fuel or tools shifting during transit.

Practical steps to calculate your single axle trailer load capacity

Follow these steps to determine usable capacity, especially when equipment or racks are added:

- Locate the GVWR on the trailer’s data plate and note the curb weight (often provided by the label or the manufacturer).

- Subtract the curb weight from the GVWR to obtain the base payload.

- Identify the tongue weight expectation, typically 9–15% of the loaded weight, and factor it into the hitch design and braking dynamics.

- Add any aftermarket equipment (racks, spare tires, tool boxes) and estimate how much weight they contribute; subtract that from the base payload if necessary.

- Consider legal limits (state or federal) that may cap payload or require brakes on trailers of certain GVWRs.

- Validate your calculation by weighing loaded trailers at a scale or by measuring with a calibrated method and comparing with manufacturer data.

This approach aligns with Load Capacity’s recommended practice: treat GVWR as the ceiling, then audit every load point (curb weight, tongue weight, and added gear) to ensure the final payload remains within safe limits.

Common pitfalls that reduce usable capacity beyond the label

Even with the label in hand, several factors can erode usable capacity:

- Improper weight distribution: Concentrating weight at the rear or forward can alter tongue load and handling, reducing effective payload.

- High tongue weight: Excessive tongue weight increases hitch forces and can compromise steering or braking performance.

- Additional equipment: Racks, spare tires, or mounted generators add payload and sometimes reduce available payload disproportionately if not accounted for.

- Tires and brakes: If tires are underinflated or brakes are undersized for the load, the trailer will require more margin to stay within safe operating conditions.

- Dynamic loads: Road irregularities, acceleration, and braking can temporarily increase axle loads above static calculations; always include a safety margin.

- Regular maintenance gaps: worn bearings, bent axles, or compromised suspension can shift load-bearing characteristics and reduce capacity over time.

Load Capacity’s 2026 guidance urges engineers to reassess capacity whenever cargo configurations change, or when upgrading components that alter weight distribution.

Real-world scenarios: quick calculations for common trailers

Example A: A small utility trailer with GVWR 3,500 lbs and curb weight of 900 lbs has a base payload of 2,600 lbs. If you expect tongue weight to be 10% of the loaded mass, plan for approximately 260 lbs of tongue load, which reduces usable payload to around 2,340 lbs. Example B: A larger single-axle utility trailer with GVWR 5,000 lbs and curb weight 1,400 lbs yields a base payload of 3,600 lbs. With an anticipated tongue weight of 12% of the total, usable payload drops to roughly 3,100 lbs after factoring tongue load. These examples illustrate how even modest changes in curb weight or load distribution can move you across practical safety margins. The exact numbers depend on axle rating and manufacturer data, so always verify against the spec plate and, if possible, confirm with a weight check at a scale.

Safety considerations, maintenance, and regulatory context

Safety first means respecting the GVWR, avoiding overweight scenarios, and ensuring all components are compatible with the load. Before each trip, verify tire condition and pressure, inspect the hitch, brakes, lighting, and suspension for wear, and ensure cargo is secured and balanced to minimize shifting. Regulations vary by jurisdiction, and some states require brakes, lights, or specific license classifications for heavier single-axle trailers; consult local authorities for compliance. Load Capacity’s guidance in 2026 emphasizes ongoing verification against the manufacturer’s spec plate and periodic re-weighing as equipment changes. For credibility, see listed authorities and resources: https://www.fhwa.dot.gov, https://www.nhtsa.gov, and https://www.transportation.gov. These references support best practices for safe operation and help engineers plan loads that stay within legal and mechanical limits.

Typical ranges for common single axle trailer configurations

| Trailer Type | GVWR (lbs) | Typical Payload (lbs) |

|---|---|---|

| Small utility trailer | 2,000–3,500 | 800–1,800 |

| Mid-size utility trailer | 3,500–4,500 | 1,000–2,000 |

| Car hauler (lightweight) | 4,000–7,000 | 2,000–3,500 |

Quick Answers

What defines GVWR for single axle trailers?

GVWR is the maximum safe gross weight a trailer can carry, including its own weight and cargo. It sets the ceiling for payload and influences braking and suspension requirements. Always use the GVWR label from the manufacturer as the primary reference.

GVWR is the max safe weight on the trailer, including the trailer itself; use it as the ceiling for payload and checks.

Can I exceed the label on my trailer by redistributing weight?

No. The GVWR reflects structural and braking limits. Weight distribution matters for handling, but the label remains the safety cap. If you routinely load toward or beyond the limit, reassess or upgrade components.

No, the rating is the limit. Distribution matters, but you should not exceed it.

How do I measure curb weight accurately?

Curb weight is the trailer’s weight with no cargo or accessories. Many dealers provide this data, or it can be verified on a scale with the trailer hitched or unhitched. Use the scale reading as the baseline for payload calculations.

Weigh the empty trailer at a scale to get the curb weight, then subtract from GVWR.

What factors reduce usable capacity beyond the GVWR?

Tongue weight, added equipment, and improper distribution can erode usable payload. Tires, brakes, and suspension quality also influence the safe margin. Plan with a conservative buffer to account for dynamic loading.

Tongue weight and extra gear can eat into usable payload; plan with a safety margin.

Are there safety regulations for trailers?

Regulations vary by state and trailer size. Some locations require brakes on heavier single-axle trailers and mandate proper lighting and license classifications. Always check local rules before operation.

Rules differ by location; check local laws and ensure compliance before use.

“Accurate trailer load capacity comes from checking GVWR, subtracting curb weight, and accounting for tongue load, with a conservative reserve for dynamic conditions. The Load Capacity Team recommends regular rechecks anytime you modify cargo, add accessories, or upgrade equipment.”

Top Takeaways

- Know the GVWR and curb weight before loading.

- Calculate payload as GVWR minus curb weight, then adjust for tongue weight.

- Account for added gear and distribution to avoid exceeding safe limits.

- Use a weight check or scale for verification, not guesses.

- Consult Load Capacity Analysis, 2026 for conservative loading guidance