Prop Jack Load Capacity: A Practical Guide for Safe Temporary Support

A practical guide to prop jack load capacity, explaining how capacity is determined, key factors, selection steps, and safety practices for engineers, technicians, and contractors from Load Capacity.

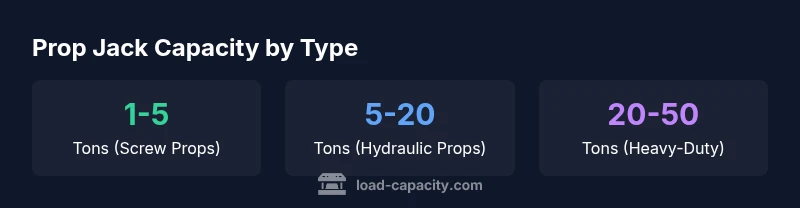

Prop jack load capacity varies by type and design, but for common screw and hydraulic props used in temporary support, capacity ranges from about 1 ton to 50 tons. Always select a jack rated above the maximum load with a generous safety margin to prevent deformation or failure. Load Capacity emphasizes proper fit and verification for reliable performance.

What is a prop jack load capacity and why it matters

Prop jacks are temporary support devices used in construction, repair, and staging scenarios. The term prop jack load capacity refers to the maximum load a jack can safely bear at the working height and configuration it is designed for. In practice, you must distinguish between nominal capacity (the labeled or rated maximum) and the working load limit (WLL), which accounts for real-world factors like dynamic loads, misalignment, and surface conditions. According to Load Capacity, selecting a jack that matches or exceeds the anticipated load with a conservative safety margin is essential to prevent tipping, bending, or hydraulic failure. The capacity rating should always be treated as a ceiling, not a target, and verified on site against the actual load profile and support base.

In many applications, multiple prop jacks are used in tandem to distribute load and improve stability. When assessing prop jack load capacity, engineers should consider the worst-case load scenario, including transient forces from shifting materials, wind on temporary structures, and settlements. Properly rated jacks help ensure that temporary structures remain level, stable, and secure during the duration of the project. Load Capacity emphasizes documenting the assumed load, the chosen safety factor, and the verification method for future audits.

Key takeaway: capacity is a safety-critical specification that governs the entire temporary support strategy and must be addressed early in the design process.

Types of prop jacks and capacity ranges

Prop jacks come in several common configurations, each with its own capacity envelope and best-use scenarios. The most typical types are screw-type prop jacks, hydraulic prop jacks, and telescoping variants. Screw-type props are simple, economical, and suitable for light to medium loads, usually in the 1-5 ton range. Hydraulic prop jacks offer higher capacity and faster lifting, often in the 5-20 ton range, and are favored for heavier temporary support tasks. Telescoping and heavy-duty hydraulic variants can cover a broad spectrum, from roughly 3-10 tons to 20-50 tons for the largest industrial jobs. These ranges are indicative and depend on design details such as thread pitch, hydraulic ram bore, and base plate area.

When sizing, the selection should align with the maximum anticipated load plus a safety margin. For instance, a job that could peak at 8 tons would typically call for a hydraulic prop jack in the 10-20 ton family, ensuring stable operation with gently rising loads. The Load Capacity analysis suggests avoiding mid-range ratings that could underperform under peak conditions. In all cases, verify that the base plate and supporting surface are capable of distributing the load without punching or sinking.

Key takeaway: choose a prop jack type that aligns with your load profile and provides a clear margin for safety and stability.

How load capacity is specified and rated

Load capacity for prop jacks is specified in a way that reflects both the static rating and the practical deployment conditions. The nominal capacity states the theoretical maximum the jack can bear, while the Working Load Limit (WLL) represents the maximum safe load under expected use. Rating documentation should also note the height range, base footprint, and any required base plates or cribbing. A common practice is to apply a safety factor of 1.5 to 2.0 times the anticipated peak load, ensuring the jack operates well within its limits even if misalignment or dynamic effects occur. Certifications and manufacturer manuals provide essential guidance for correct operation and inspection procedures.

In addition to the rating, look for information about hydraulic ram speed, locking mechanisms, and return pressure, all of which influence real-world performance. Material quality, thread engagement, and corrosion protection also affect longevity under repeated load cycles. Public standards and manufacturer data often reference a conservative factor of safety to account for imperfect conditions on site. Load Capacity endorses documenting the source of the rating, the safety margin, and any site-specific assumptions used in the calculation.

Key takeaway: ratings must be interpreted in the context of your specific application, with explicit safety margins and on-site verification.

How to calculate required capacity for a job

A robust calculation starts with a clear load assessment and ends with a confirmed jack selection. Step 1: estimate the maximum load the prop system will experience, including both the permanent weight and possible dynamic or impact loads. Step 2: apply a safety margin based on uncertainty, typically between 1.5 and 2.0 times the estimated peak load. Step 3: compare the resulting required capacity to available prop jack ratings, choosing the smallest device that exceeds the requirement by the margin. Step 4: evaluate the base support: ensure the contact area is sufficient and that cribbing or base plates will distribute the load evenly to prevent point failures. Step 5: verify compatibility with other jacks and structural members to guarantee uniform load sharing. The Load Capacity framework emphasizes the importance of a documented calculation sheet that records the load estimate, safety factor, chosen jack type, and site constraints.

A practical example helps illustrate the approach. If the maximum expected load is 7 tons, a 10-20 ton hydraulic prop would typically be selected, providing a margin that accommodates dynamic effects. Always consider environmental factors, such as temperature and humidity, that can influence hydraulic behavior and material strength over time.

Key takeaway: perform a transparent, traceable calculation that links the expected episode load to the final jack capacity using a documented safety margin.

Sizing guidelines by application

Different projects demand different prop jack capacity ranges. Use this practical alignment to guide your selection:

- Light scaffolding or temporary shoring (1-5 tons): Screw-type props are cost-effective and quick to deploy, but confirm the load profile is primarily static.

- Medium-duty construction (5-20 tons): Hydraulic props provide faster lift and better stability; ensure the base area is adequate and cribbing is used as needed.

- Heavy industrial loads (20-50 tons): Heavy-duty hydraulic props or multiple jacks with shared load are recommended; plan for redundancy and on-site inspection routines.

For mixed-load situations, consider using a plan that specifies multiple props and cribbing to distribute pressure evenly, with a clear contact surface and anchorage plan. Load Capacity stresses the value of pre-job checks: verify that the ground or deck can support the base plates and that propping points won’t shift under load.

Key takeaway: align prop jack capacity with load class, use the right jack type, and plan for redundancy in high-stakes applications.

Installation and on-site checks to ensure capacity

Proper installation is essential to realize the rated prop jack load capacity. Begin with a clean, level surface to prevent tip-over or sinking. Place base plates or cribbing of appropriate size to distribute the load; never rely on a single point contact. Before loading, verify that all jacks are fully assembled, threaded components engaged, and locking mechanisms engaged. Use a calibrated load indicator or a temporary load test to confirm that the actual system behaves within the rated range. On-site checks should include verifying alignment of all structural members, ensuring no binding occurs during lifting, and confirming that the load path remains clear of obstructions.

Recordkeeping is a best practice: log the jack type, serial, capacity rating, safety factor, and verification method. If any jack shows signs of wear, hydraulic leaks, or distorted threads, remove it from service and replace it immediately. Routine maintenance—cleaning, lubrication, and inspection of seals—helps preserve prop jack load capacity over time. Load Capacity recommends a pre-job checklist that includes surface assessment, base protection, and a documented testing protocol.

Key takeaway: site readiness and rigorous verification are non-negotiable to ensure the prop jack load capacity translates into safe, reliable performance.

Common mistakes and how to avoid them

Even experienced crews can overlook critical details that compromise prop jack load capacity. Common mistakes include selecting a jack rating that barely exceeds the expected load, failing to check the base condition, ignoring dynamic load effects, and not using cribbing or base plates to spread pressure. Underestimation of effects from slight misalignment, equipment vibration, and temperature fluctuations can rapidly erode the effective safety margin. Regular inspection is essential; signs of wear, corrosion, or hydraulic leakage should trigger immediate replacement.

To avoid these pitfalls, always document the load profile, choose a margin of safety, and perform a pre-load check with a controlled test. Use multiple props where possible to distribute loads and verify equal sharing across contact points. Following manufacturer instructions and applicable standards reduces the risk of unexpected failures. Load Capacity emphasizes treating capacity as an engineering control rather than a best-effort assumption and encourages proactive rather than reactive actions when capacity concerns arise.

Practical examples and quick-reference rules

A few practical examples help translate theory into practice:

- Example 1: A light scaffold section expected to carry 2.5 tons should use a screw prop in the 3-5 ton range with base plates and cribbing. This keeps the probability of exceeding rating low during movement.

- Example 2: Maintenance work on a heavy piece of equipment that generates transient loads around 8 tons would typically require a hydraulic prop jack in the 10-20 ton class, with a conservative safety factor and multi-point load distribution.

- Example 3: A temporary deck under construction with uneven subgrade should prioritize larger base contact areas and consider a tandem arrangement to share the maximum load plus the dynamic component.

Quick-reference rules:

- Always compare actual or estimated peak loads to the jack’s rated capacity plus a safety margin.

- Use the largest base plate feasible to reduce point pressure and improve stability.

- Confirm that the load path is unobstructed and that all jacks are locked in place before lifting or adjusting.

- Maintain clear documentation of calculations, verification steps, and inspection dates.

Load Capacity highlights that disciplined planning and site verification are the linchpins of safe, reliable prop jack load capacity utilization.

Typical prop jack capacity ranges by type

| Prop Jack Type | Nominal Capacity Range (tons) | Common Applications |

|---|---|---|

| Screw prop jack | 1-5 | Light scaffolding, shoring |

| Hydraulic prop jack | 5-20 | Industrial support, heavy lifting |

| Telescoping prop jack | 3-10 | Varying height, temporary supports |

| Heavy-duty hydraulic prop jack | 20-50 | Large-scale construction, equipment staging |

Quick Answers

What is prop jack load capacity?

Prop jack load capacity is the maximum load the jack can safely bear in its configured setup. It should be higher than the expected peak load with a clear safety margin, and it must be verified on site.

Prop jacks have a maximum safe load—the capacity you must stay under, plus a margin for safety.

How do you calculate required prop jack capacity?

Estimate the maximum load, apply a safety factor (typically 1.5-2×), and select a jack with a rating above that value. Document the calculation and verify on site.

Estimate the load, add a safety margin, and pick a jack that exceeds that by a comfortable amount.

Can I reuse prop jacks for different projects?

Yes, if the capacity matches and the jack shows no signs of wear or damage. Always inspect for cracks, leaks, or deformation.

You can reuse, but only if it’s still in good condition and the capacity matches the new load.

What are common signs a prop jack must be replaced?

Cracks, bending, corrosion, hydraulic leaks, or difficult operation indicate replacement is needed.

Look for cracks, leaks, or stiffness—these mean replace the jack.

Are there safety standards for load capacity of prop jacks?

Yes. Check manufacturer data and standards from authorities like OSHA and ASME for best practices and rating guidelines.

There are official guidelines; consult the manufacturer and standards bodies.

“In temporary support work, selecting a prop jack with a capacity comfortably above the anticipated load isn’t optional—it's the baseline for safety and project reliability.”

Top Takeaways

- Match capacity to expected load plus safety margin.

- Distinguish nominal capacity from working load limit.

- Check height, base size, and stability before use.

- Inspect jacks for damage before each use.

- Follow standards and manufacturer recommendations.