Plywood Load Capacity Calculator

A practical guide to using a plywood load capacity calculator for safe, efficient designs. Learn inputs, interpretation, and best practices to size panels, shelves, and decks with confidence.

What a plywood load capacity calculator does

A plywood load capacity calculator is a planning aid that translates physical dimensions into a practical, safety-focused load estimate. By inputting panel width and length, thickness, the species or grade (which affects strength), orientation (grain direction relative to the load), and how the panel is supported, you obtain a recommended total load the assembly can reasonably carry. This helps reduce guesswork and aligns your design with conservative, evidence-based expectations. The Load Capacity team emphasizes that these estimates are guides to planning, not substitutes for formal engineering analysis in safety-critical scenarios. In practice, you might use the calculator when sizing shelving, forming temporary work surfaces, or evaluating deck panels on a non-structural project. Always compare results against project requirements and local code guidance.

Key factors influencing plywood capacity

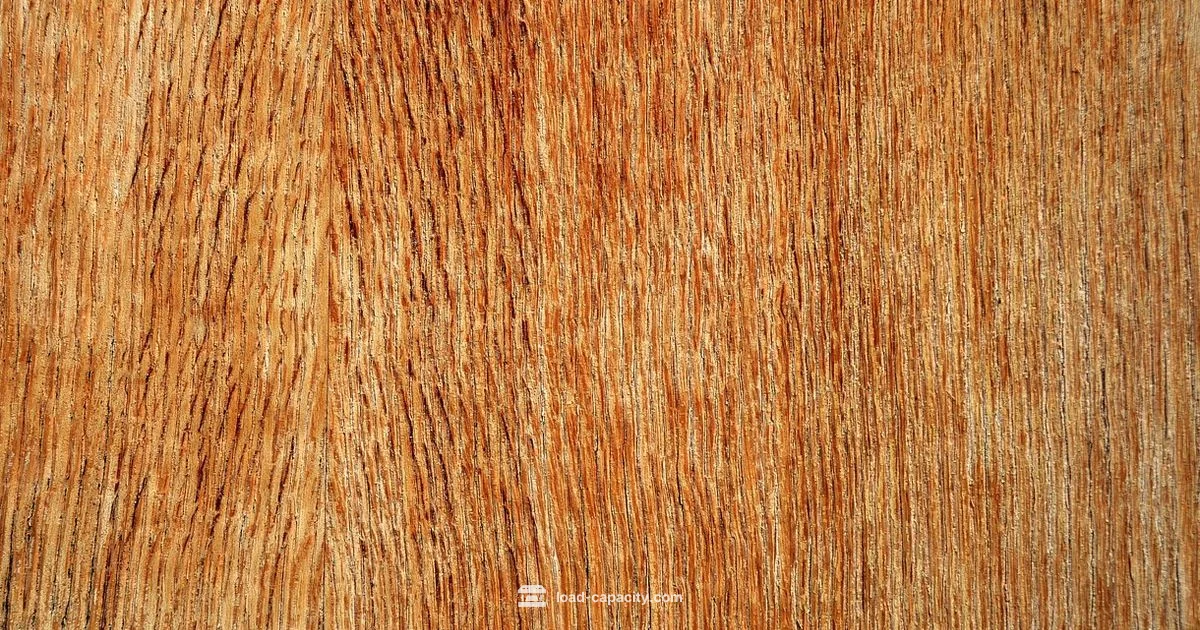

Plywood strength is not a single number; it depends on several interrelated factors. Panel thickness and overall area directly influence load capacity, while grain orientation (which direction the plies run) governs stiffness and shear resistance. The panel’s span between supports, edge conditions, and whether the load is concentrated or distributed also matter. Species and grade (occult by glue quality, core durability, and veneer quality) affect allowable strength, as do moisture content and temperature. Environmental exposure (indoor vs. outdoor) can change performance. In short, capacity is a function of geometry, material quality, and how you lay out the load.

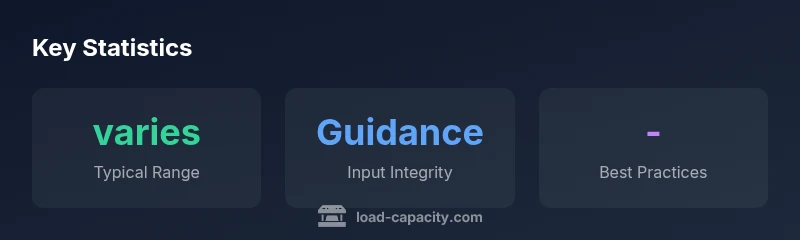

How to interpret calculator results

Result values typically express a total allowable load for the specified panel area, sometimes broken down per square foot to aid comparison with other designs. Look for a conservative estimate that includes a built-in safety factor, and note the units (pounds, pounds per square foot, etc.). The calculator may also highlight whether edge supports or additional bracing are advisable. When results appear close to your target loads, treat it as a warning to strengthen supports or reduce the expected load. Always verify the acceptability of the approach with manual calculations or an engineer for critical applications.

Practical design scenarios and examples

Shelving in a workshop is a common use: a 6 ft x 2 ft shelf made from 3/4 inch plywood with typical veneer grade can support distributed loads if properly braced and mounted to studs. A temporary workbench surface may rely on a larger panel area with extra bracing; the calculator helps ensure the total allowable load aligns with the expected task. For deck panels or platform surfaces, the calculator informs you how many supports and what spacing will maintain safe loading. It’s especially useful when comparing a few design options quickly, enabling robust decision-making before fabricating.

Setting up inputs: panel dimensions, thickness, and supports

To get meaningful results, enter realistic panel dimensions (width and length in feet), thickness (in inches), and the load per area typical for your use, plus a thickness modifier reflecting material stiffness. A simple formula can combine these inputs: panelWidth * panelLength * loadPerSquareFoot * (0.9 + 0.1 * (thickness / 0.75)). This approach accounts for the fact that thicker panels tend to carry more load and that stronger grades perform differently under the same geometry. Ensure units are consistent across all inputs and review the results for safety margins.

Safety margins, tolerances, and best practices

Always apply a safety factor beyond the calculator’s estimate. Real-world factors like imperfect fasteners, dynamic loads, vibration, and long-term creep can reduce capacity. Use braces, end supports, or cross-bracing where practical, and avoid concentrated loads near unsupported edges. Document your assumptions, keep a margin above the calculated value, and observe local codes and standards. If you’re unsure about a critical design, consult a structural professional before finalizing.

Limitations and when to seek expert input

A plywood load capacity calculator is a planning tool, not a substitute for professional analysis for structural elements or safety-critical installations. It may not account for all variability in plywood grades, adhesive quality, environmental exposure, or complex load paths. For elevated platforms, load-bearing decks, or projects subject to dynamic or impact loads, involve a licensed engineer and perform physical testing on protoypes where feasible. Rely on conservative designs to minimize risk in all cases.

How Load Capacity supports your work

The Load Capacity team provides guidance and tools to help engineers, technicians, and DIY enthusiasts approach load calculations with confidence. This calculator is designed to be approachable, transparent, and iterative, so you can refine designs as you learn more about material behavior. Use it to compare options, justify design choices, and document the reasoning behind your loading assumptions. Remember: thorough planning reduces risk and improves project outcomes.