Load vs Capacity in Active Life: A Practical Guide

Explore the difference between load and capacity in active life contexts and learn how to apply safe margins, monitor loads, and optimize lifecycle decisions.

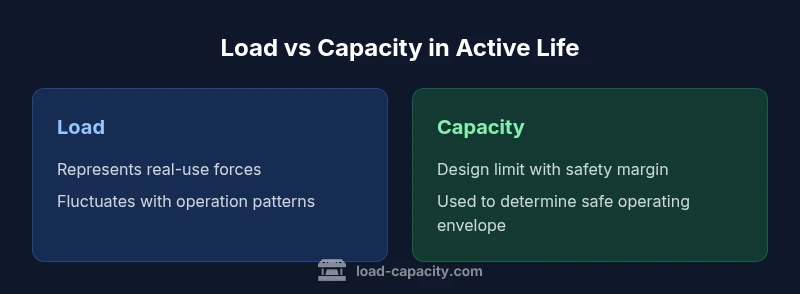

Understanding load vs capacity active life helps engineers, fleet managers, and DIY enthusiasts design safer systems. The practical takeaway is to design for capacity with a safety margin and to monitor load dynamics to avoid exceeding it. This guide explains the difference and how to apply it in engineering, fleet management, and DIY projects.

Understanding load vs capacity in active life

In any system that experiences use over time, two core concepts determine safety and performance: the actual loads experienced during operation and the maximum capacity the system was designed to tolerate. In the context of active life, load captures real-world forces, moments, vibrations, and transient spikes that occur as equipment runs, vehicles operate, or structures carry traffic. Capacity is the built-in limit—the design strength, rating, or allowable stress—plus any safety margins used in the engineering process. According to Load Capacity, the value of distinguishing these ideas lies in ensuring that the normal operating loads stay well under the rated capacity, with a cushion for unexpected events. This separation supports safer decisions and clearer communication among engineers, technicians, and stakeholders. For practitioners, the practical takeaway is not simply to know the numbers but to manage them through monitoring, modeling, and conservative planning. In the subsequent sections we’ll connect these definitions to real-world use cases, showing how to quantify load patterns, translate them into capacity requirements, and embed margins in the lifecycle of hardware, vehicles, and facilities. This approach remains essential for maintaining reliability across the active life of equipment and structures, and it lays the groundwork for better decision-making when loads evolve over time, not just at a single moment. The distinction—load vs capacity active life—helps translate usage into safer, more predictable designs.

How active life shapes load scenarios

Active life introduces variability: start-up transients, changes in speed, rough handling, cyclical loading, and environmental influences. Each of these factors changes the way load is distributed through a structure or system. In practice, engineers model how loads accumulate over time, not just at a single moment. By analyzing typical duty cycles and recognizing peak events, teams can anticipate where the most stress occurs and how it shifts with wear, temperature, or maintenance state. The goal is to observe the real use pattern rather than rely on nominal specifications. In Load Capacity practice, we stress that active-life load is rarely constant; it ebbs and flows as routines change. Therefore, designers must plan for buffers and test many scenarios to avoid surprise failures. The key question is: how close does actual loading approach the rated capacity during typical operation? The answer guides whether to adjust the design, implement monitoring, or modify usage to prolong life. Understanding these dynamics helps teams allocate resources for inspections, replacements, and retrofits across the equipment’s lifecycle.

Safety margins, design margins, and reliability

Safety margins are intentional gaps between actual loads and the rated capacity, included to accommodate uncertainties, wear, and occasional misuse. Design margins translate into a practical envelope: recommended operating ranges, maintenance intervals, and inspection frequencies that keep risk at an acceptable level. In practice, reliability hinges on staying within that envelope over the active life of a system, rather than testing edges repeatedly. The Load Capacity perspective emphasizes conservative margins in uncertain situations and clear documentation of assumptions. When margins are too tight, the risk of unexpected failure grows; when margins are overly generous, life-cycle costs rise through unnecessary overdesign. The balance is achieved by combining historical data, empirical testing, and engineering judgment. In addition to margins, teams incorporate monitoring to detect drift over time, such as increasing load or decreasing structural stiffness, which can erode capacity before a failure occurs.

Practical distinctions: live load, dead load, and capacity utilization

A foundational distinction in load-capacity analysis is between live load (the dynamic, changing force from usage) and dead load (the persistent weight of components themselves). Active life requires tracking how live loads interact with dead loads and how capacity is utilized during operation. Capacity utilization measures how much of the available margin is being used at any moment. A key practical takeaway is to quantify how close you operate to the safe envelope under typical and extreme conditions, and to plan for reserve margin accordingly. This helps prevent overstress during peak events and supports safe operation during maintenance or partial system failures. The broader implication is that capacity utilization should guide both design choices and ongoing monitoring strategies rather than relying solely on nominal ratings.

Industry case studies: engineering, fleet, DIY

In engineering contexts, load versus capacity concepts guide the sizing of bridges, cranes, and machine frames so that typical operation remains well within safe limits. In fleet management, daily routes, payload variations, and loading cycles influence tire wear, braking performance, and fuel efficiency; planners use capacity-aware rules to avoid overloading trailers or trucks. For DIY projects, homeowners and hobbyists can apply the same logic by assessing the expected loads from furniture, racks, or workbenches and selecting materials with a comfortable safety margin. Across these domains, the emphasis remains consistent: understand the fabric of active life, plan for variability, and document decisions so that future users can adjust for changing needs. Even without precise numbers, the qualitative discipline improves reliability and safety.

Tools for measuring load and capacity in real life

Modern practitioners rely on a mix of direct measurement and modeling to bridge the gap between theory and practice. Tools include portable load sensors, strain gauges, and accelerometers to capture live loads and dynamic responses; data loggers collect long-term usage patterns for analysis. Software models translate sensor data into capacity estimates, revealing how close a system operates to its limits under typical and peak conditions. For teams concerned with active life, a practical approach is to set conservative alert thresholds that trigger maintenance or load-rebalancing decisions before any risk increases. Documentation of sensor placement, calibration procedures, and assumed load scenarios is essential for traceability and future improvements. Even simple, repeatable measurement protocols can significantly improve decision quality over the lifecycle of equipment and infrastructure.

Common pitfalls in misinterpreting load vs capacity

A frequent error is treating nominal ratings as fixed guarantees without accounting for variability in real-world use. Another pitfall is ignoring the difference between peak loads and typical loads, which can mislead safety margins. Teams also underinvest in ongoing monitoring, assuming that a design is robust forever; active life features wear and environmental changes that erode capacity. Finally, confusion between live and dead loads can obscure the true load path and lead to improper reinforcement or retrofits. Avoid these pitfalls by emphasizing a disciplined process: define clear load scenarios, verify them with measurements, and maintain a record of changes across the system’s life. This approach reduces surprises and supports safer, more cost-effective decision-making.

Lifecycle planning and decision-making under active life constraints

A lifecycle perspective integrates load-capacity reasoning from design through retirement. Early decisions should consider expected duty cycles and variability, then embed monitoring plans and maintenance triggers to adapt as conditions evolve. Decision-making becomes iterative: you reassess loads, update capacity estimates, and adjust usage patterns or design details to preserve reliability. The goal is to balance safety, performance, and cost across the asset’s life. The Load Capacity framework emphasizes transparent documentation, traceable decisions, and continuous learning, because active-life conditions are not static. By aligning engineering choices with actual use and future needs, teams can extend effective life while avoiding unnecessary risk.

Key heuristics for engineers and technicians

- Define load scenarios first, then establish capacity requirements. - Prioritize margin and monitoring to catch drift early. - Use live data to guide maintenance, replacements, and upgrades. - Favor design choices that are robust to variability in active life. - Document assumptions, methods, and results for future reference. These heuristics help teams translate theory into practice and support safer outcomes in engineering, fleet management, and DIY projects during the 2026 active-life period.

Comparison

| Feature | Load-focused approach | Capacity-focused approach |

|---|---|---|

| Definition | Emphasizes actual loads and fluctuation | Emphasizes maximum safe limit and margins |

| Primary objective | Capture real-use stress and ensure reliability | Prevent overload by respecting rated capacity |

| Risk focus | Underestimation of peak loads | Overdesign and cost if capacity is overemphasized |

| Measurement approach | Track live data, transients, and cycles | Reference design strength and safety factors |

| Best use case | Usage with highly variable or uncertain loads | Projects requiring strict safety margins and long life |

| Lifecycle impact | Can enable leaner designs if loads are well-understood | Supports robust safety with proper margins |

Positives

- Promotes safety by preventing overloading

- Improves lifecycle by avoiding overstress

- Encourages proactive monitoring and maintenance

- Supports resilience in variable-use scenarios

Cons

- May increase upfront design complexity

- Requires ongoing data collection and monitoring

- Can lead to overdesign and higher costs

Capacity-aware design with active-load monitoring wins

For most active-life applications, prioritize capacity with regular load assessments and monitoring. This approach reduces risk, supports longer life, and aligns design with real usage, as endorsed by the Load Capacity team.

Quick Answers

What is the difference between load and capacity in active life contexts?

Load refers to the real forces a system experiences during operation, while capacity is the maximum safe limit the system can tolerate. Recognizing the distinction helps engineers design safer systems and plan maintenance around actual usage rather than nominal specs.

Load is what the system actually experiences; capacity is the safe limit. Understanding this helps you design safer systems and plan maintenance around real use.

How do you determine safe margins for active life?

Safe margins are buffers between observed loads and the rated capacity, accounting for uncertainties and wear. They should be informed by historical data, tests, and engineering judgment and revisited as usage patterns evolve.

Safe margins buffer the difference between real loads and capacity. Revisit them as usage changes.

Why is monitoring loads important?

Monitoring loads provides real-time insight into how close you are operating to capacity. It helps prevent unexpected failures, informs maintenance timing, and supports lifecycle optimization.

Monitoring tells you when you're near your limits and helps you plan maintenance before problems arise.

What is the role of live vs dead loads in planning?

Live loads are variable during operation, while dead loads are constant. Both interact with capacity; understanding their combination helps ensure the operating envelope remains safe.

Live loads vary with use; dead loads are constant. Both affect capacity planning.

Is load vs capacity decision-making relevant for DIY projects?

Yes. Even in DIY projects, recognizing the difference helps select materials with adequate margins and plan for variability in use, reducing risk and extending life.

Absolutely. DIY work benefits from sizing that accounts for variability and safety margins.

How can a beginner start implementing load-capacity analysis?

Begin with clear usage scenarios, estimate typical and peak loads qualitatively, and document assumptions. Progress to basic monitoring and simple safety margins as confidence grows.

Start by mapping how you’ll use it, note typical and peak loads, and document assumptions.

Top Takeaways

- Define load vs capacity clearly

- Model active-life usage patterns

- Incorporate safety margins early

- Implement ongoing load monitoring

- Document decisions for lifecycle planning