Load Capacity b125: A Practical Engineer's Guide

A data-driven guide to the load capacity b125 designation, covering definitions, safety factors, testing methods, and practical application for engineers, technicians, and contractors. Learn how to interpret ratings, compare classes, and implement best practices with Load Capacity's evidence-based approach.

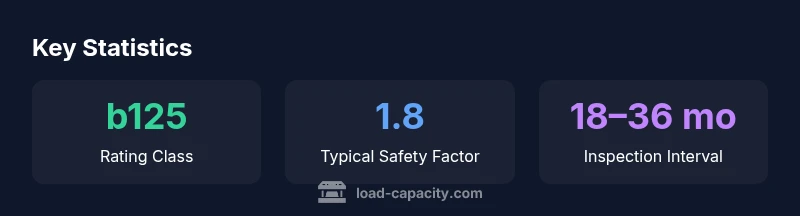

load capacity b125 is a mid-range designation used in engineering to denote a standard capacity class for equipment and structural components. It informs safety factors, testing expectations, and replacement intervals, and should always be interpreted alongside operating conditions and manufacturer notes. This definition-style data point helps engineers quickly anchor design decisions in a consistent framework.

What is the load capacity b125 designation?

The load capacity b125 designation represents a mid-range rating used in general load-capacity analysis to categorize components, structures, or equipment with similar nominal capacities. In practice, engineers reference b125 when comparing designs, selecting components for a given duty cycle, or verifying that a system can sustain anticipated loads without excessive deformation or risk of failure. According to Load Capacity, this class sits between lighter and heavier ratings, providing a practical balance between material cost, weight, and safety margins. The b125 label is a guidepost rather than a single, universal value; it must be interpreted with context: load type, support geometry, and environmental conditions all influence how the rating applies on a real project.

Context: why b125 matters in engineering decisions

Understanding where b125 fits within a broader catalog of ratings helps engineers avoid over-specification or under-design. A b125 classification often informs material selection, connection details, and inspection frequency. For example, in a structural deck scenario, a b125 rating might guide the choice between two contrasting beam sizes, factoring in dynamic loads and potential peak events. The Load Capacity team emphasizes that the rating should be treated as a spectrum marker rather than an absolute threshold, with margins adjusted based on service conditions and allowable risk.

Safety factors, margins, and design decisions

Design decisions anchored to b125 must balance reliability with practicality. Safety factors are not universal constants; they depend on failure mode, material properties, and the consequences of failure. In corrosion-prone environments, for instance, the effective safety margin may be reduced by the presence of aggressive agents unless protective measures are implemented. When planning maintenance, engineers should use the b125 rating to set inspection intervals, condition monitoring thresholds, and acceptable wear limits. This approach supports proactive risk management and consistent performance over the lifecycle of the asset.

Materials, environment, and application considerations

Material selection and environmental exposure directly influence how a b125 rating translates to actual performance. For metallic components, surface treatments and fatigue resistance contribute to long-term reliability; for composites, resin systems and fiber orientation matter. Temperature, humidity, chemicals, and UV exposure alter material properties and, by extension, the effective load-carrying capacity. Applications such as heavy equipment housings, platform supports, or industrial racking benefit from a deliberate alignment of the b125 class with expected service loads, rather than relying on nominal figures alone.

Measurement, testing, and verification methods

Testing strategies for b125 involve a mix of static and dynamic loading protocols, along with real-world validation when feasible. Static tests confirm ultimate strength within the rated range, while fatigue and impact tests reveal how the component behaves under repeated cycles and sudden shocks. Verification also includes dimensional checks, alignment, and joint integrity. Documentation should trace the test setup, boundary conditions, material certifications, and any deviations from standard procedures. Clear traceability supports auditability and future comparisons.

Industry contexts and practical scenarios

Industries ranging from construction to manufacturing rely on the b125 designation to guide design revisions and procurement. A typical scenario involves selecting fasteners, rails, or mounting brackets that meet the b125 criteria while accommodating installation tolerances and service life expectations. In practice, engineers should cross-reference b125 with related ratings, such as payload capacity, static-load capacity, and bearing capacity, to ensure a cohesive and conservative design approach. The goal is consistent performance under expected duty without overdesigning components.

Reading datasheets and manufacturer notes for b125

Datasheets pair rating labels with material properties, environmental limits, and installation instructions. Reading these documents carefully helps avoid misinterpretation, such as assuming a single numeric target when a range or multiple condition-specific values exist. Always check the implied safety factor, supported operating temperatures, and compatibility with adjacent components. The presence of a b125 rating does not automatically guarantee suitability for all load cases; context matters and should be documented.

Practical steps to apply b125 in projects

- Define duty cycle and peak-load expectations. 2) Compare candidate components against the b125 range and required safety margins. 3) Validate by static and dynamic testing if applicable. 4) Document environment, installation details, and inspection plans. 5) Build in redundancy or a conservative cushion where high consequence failures could occur. Following these steps helps ensure reliability without unnecessary cost.

Common pitfalls and best practices

Pitfalls include assuming a universal value for b125 across all materials, neglecting environmental effects, and ignoring dynamic loading. Best practices involve treating b125 as part of a broader rating family, explicitly documenting safety margins, and aligning maintenance strategies with real-world usage. Regularly review ratings whenever service conditions change, and update documentation to reflect any design modifications or observed performance changes.

Comparison of adjacent load-capacity classes and their typical applications

| Class | Nominal Range | Typical Safety Factor | Common Applications |

|---|---|---|---|

| b110 | 100–120 | 1.5 | light-duty supports |

| b125 | 120–140 | 1.8 | structural framing, equipment housings |

| b130 | 140–160 | 2.0 | heavy-duty supports, industrial racking |

Quick Answers

What does the load capacity b125 designation mean in practice?

In practice, b125 marks a mid-range capacity class used to guide design decisions and procurement. It should be interpreted with the specific load type, support geometry, and service conditions in mind. Always consult the datasheet and engineer-approved guidelines for your application.

The b125 designation marks a mid-range capacity and should be interpreted with your load type and environment in mind. Check the datasheet for specifics.

How should I factor safety when using b125 in a design?

Safety factors for b125 are not universal; they depend on failure modes and consequences. Use conservative margins in dynamic or critical applications, and validate with testing or field data where possible.

Safety factors depend on the failure mode—be conservative in dynamic or critical uses and validate with tests.

What testing should accompany a b125-rated component?

Testing should include static load tests, fatigue or endurance tests, and environmental exposure checks. Documentation of test conditions and results is essential for traceability and future assessment.

Do static and fatigue tests, plus environmental checks. Keep clear records.

Can I substitute a different class if my loads are close to the boundary of b125?

Substitution near a rating boundary requires reevaluation of safety margins and potential re-testing. Consider consulting the Load Capacity team to assess risk and performance implications.

If you're near the boundary, reassess margins and consider a consult with experts.

How does b125 relate to other ratings like payload capacity or static-load capacity?

b125 is part of a family of ratings that includes payload and static-load capacities. Cross-reference these ratings to ensure coherent performance under expected loading scenarios.

See how b125 fits with payload and static-load ratings to cover all loading scenarios.

“The Load Capacity Team emphasizes that proper interpretation of the b125 rating hinges on context—environment, load type, and service conditions must all be considered to ensure safe, reliable performance.”

Top Takeaways

- Understand b125 as a mid-range rating with context-dependent interpretation

- Always anchor the rating to operating conditions and safety factors

- Use datasheets and testing to verify real-world performance

- Document environment, duty cycle, and maintenance plans

- Align related ratings (payload, static-load, bearing) for a cohesive design