How to Calculate Load Capacity: A Practical Guide for Engineers

Learn how to calculate load capacity for structures, vehicles, and equipment with a step-by-step approach. This expert guide from Load Capacity covers inputs, safety factors, and verification against codes to ensure safe, compliant results.

This guide teaches how to calculate load capacity for structures, vehicles, and equipment. You’ll identify all relevant loads, apply safety factors, and verify against applicable codes. By following these steps, you’ll determine the maximum permissible load for a given component, reducing risk, preventing damage, and ensuring ongoing compliance.

How to calculate load capacity in practice

According to Load Capacity, understanding how to calculate load capacity starts with defining the scope and listing every load that acts on a component. Whether you're sizing a structural beam, selecting a forklift, or evaluating an appliance in a machine suite, the same disciplined approach applies. This article explains the why and the high-level method before we dive into formulas and examples. The goal is to quantify the maximum safe load that the element can carry under real-world conditions, including static and dynamic effects, temperature, and manufacturing tolerances. By the end, you’ll know what inputs you need, how to organize them, and how to verify results against applicable codes and manufacturer data. Load Capacity's guidance emphasizes safety, reliability, and compliance, so you can communicate assumptions clearly and defend your calculations during audits or design reviews.

The process begins with a clear definition of scope: are you assessing a structural member, a piece of equipment, or a system with multiple interacting parts? Once scope is set, you list all potential loads—static weight, dynamic forces from movement, impact loads, and any auxiliary loads such as wind or acceleration. The next step is to collect reliable data sources, including manufacturer specifications, prior test results, and reference codes. Finally, you establish a consistent method for combining these inputs into a single capacity figure that can be checked against known limits. Throughout, maintain traceability so future designers can audit your work.

Key concepts: loads, safety factors, and capacity

Load capacity is the maximum load that a component can safely carry under defined conditions. To manage uncertainty, engineers apply safety factors, which reduce the usable capacity to a conservative value. This balance between strength and reliability is central to safe design. Distinctions matter: static loads are steady forces, while dynamic loads involve motion, acceleration, or changing conditions. A well-structured calculation separates these categories and treats them with appropriate factors. When you document the results, include units, sources, and assumptions so reviews can verify every input and decision. In practical terms, you’ll compare the final allowable load to the expected service loads and ensure an adequate margin for variability, degradation, and aging. The aim is not to maximize a number but to assure safe operation over the component’s life.

Understanding these concepts helps prevent under- or over-sizing, both of which carry risks—from unnecessary cost and weight to failure during peak conditions.

Data inputs, units, and data quality

Accurate load capacity calculations rely on high-quality inputs gathered from reputable sources. Start by listing all loads and their directions of action, then convert all quantities to a common set of consistent units. Document the basis for each input: manufacturer datasheets for equipment, material strength data from standards, or measured field data where applicable. Pay attention to environmental conditions such as temperature, humidity, and vibration, which can alter material properties and dynamic responses. Finally, establish a data quality rubric: traceability, version control, and source reliability. The better your inputs, the more trustworthy your result. When in doubt, cross-check with multiple sources and note any uncertainties clearly for future review.

Practical example: calculating load capacity for a structural beam

In a typical beam-sizing scenario, you begin with the beam’s geometry, material, and support conditions. Next, identify all loads acting on the beam—using your scope from the previous sections—and convert them to a common unit. Apply any applicable factors, such as a dynamic multiplier for moving loads, and sum the factored loads. Compare this total to the beam’s capacity data from manufacturer tables or codes, ensuring a safety margin remains. If the factored load exceeds capacity, you must redesign or reduce service loads. Document the calculation steps, inputs, and final decision clearly so peers can review your work. This exercise demonstrates how the same disciplined approach scales from simple devices to complex structures.

Practical example: calculating load capacity for a forklift or vehicle payload

Vehicle payload calculations require recognizing both static weight (the empty mass) and dynamic effects (loading/unloading, acceleration). Start by listing all items the vehicle carries, including palletized goods and attachments. Convert weights to a single unit and sum them. Then apply a safety factor appropriate to operating conditions, surface, and maintenance history. Compare the result to published vehicle capacity data from the manufacturer, and ensure the rated capacity includes any added accessories. If the calculated load approaches limits, reassess with alternative configurations or equipment. Document assumptions and the sources of capacity data to support inspections or audits.

Safety factors, codes, and data sources

Engineering practice relies on safety factors to account for uncertainties in loads, material properties, and aging. The chosen factor reflects the reliability required for function, risk tolerance, and the consequences of failure. In most jurisdictions, you will reference codes, standards, and manufacturer data to validate capacity figures. Always verify whether a dynamic or fatigue factor is needed for your application. Moreover, cross-check calculations against documented test results or peer reviews when available. The key is to build a defensible, auditable trail that demonstrates the calculation can withstand uncertainties across the component’s life cycle.

When in doubt, consult a qualified engineer and reference the latest edition of applicable standards. Load Capacity's 2026 guidance emphasizes transparent methods, so your team can defend design decisions under scrutiny.

Common mistakes and how to avoid them

Common pitfalls include mixing units, omitting critical loads, or using outdated data. Another frequent error is treating safety factors as an optional step rather than an integral part of the calculation. To avoid these issues, adopt a checklist that enforces unit consistency, requires explicit input sources, and mandates a peer review. Keep records of assumptions, such as temperature effects or manufacturing tolerances, and revisit them when configurations change. Finally, verify your final result with a sensitivity analysis: explore how small changes in inputs influence the outcome, so you understand the robustness of your decision.

Documentation, verification, and change control

A robust load capacity calculation lives in a well-organized document that captures inputs, formulas, and rationale. Use version control for every revision and attach the sources for data used in the calculation. Include diagrams or photos of the component, a summary of service conditions, and the final verdict (safe or not safe) with the margin of safety. Establish an approval workflow: designer, reviewer, and approver signatures or initials. Schedule periodic re-evaluations when changes occur in loads, geometry, or operating conditions. A clean, auditable record protects against misinterpretation in audits and helps future teams quickly update the assessment.

Quick-start checklist before operation

Before putting any component into service, confirm you have: a complete list of loads, consistent units, safety factors applied, verified capacity data, and a documented decision. Ensure you’ve captured environmental and dynamic considerations, and that results are reviewed by a peer. Finally, store your calculation in a location accessible to the team and maintain an update log for future reference.

Tools & Materials

- Scientific calculator or calculator software(Casual desktop or mobile app; includes algebra, unit conversion, and basic trigonometry.)

- Measuring tape or ruler(Essential for gathering physical dimensions or verifying component geometry.)

- Manufacturer data sheets / code references(Source of capacity data and material properties; keep copies for audit.)

- Unit conversion chart or converter(Ensure consistent units (e.g., N, kN, lb, kg) across inputs.)

- Notebook or digital documentation(Record inputs, formulas, assumptions, and results with timestamps.)

- Personal protective equipment (PPE) for on-site work(Use when collecting measurements on active sites; not required for pure calculations.)

Steps

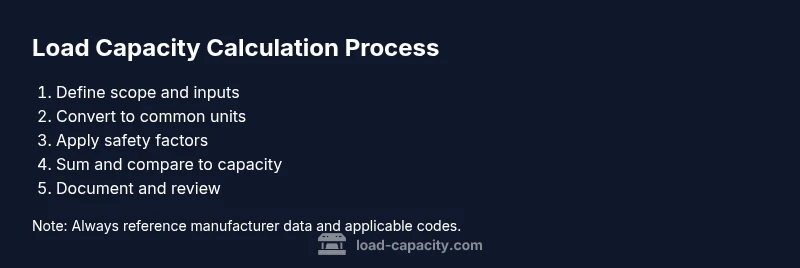

Estimated time: 60-120 minutes

- 1

Define scope and identify all loads

State the component or system being analyzed and list all loads that affect it. Include static weights, dynamic forces from motion, impact loads, and environmental effects if applicable.

Tip: Create a one-line scope statement you can reuse in calculations and reviews. - 2

Collect reliable input data

Gather data from manufacturer sheets, standards, tests, or validated measurements. Ensure sources are current and traceable to avoid outdated assumptions.

Tip: Document the source and date of every input for auditability. - 3

Convert all inputs to a common unit

Choose a base unit (e.g., Newtons or pounds) and convert every load accordingly. This prevents arithmetic errors during summation.

Tip: Double-check conversions with a quick cross-check using a different tool. - 4

Apply safety factors to loads as required

If the application involves uncertainty or variability, apply a factor of safety to each load before summation.

Tip: Keep a record of the safety factor rationale in your notes. - 5

Sum factored loads and compare to capacity data

Add all factored loads to obtain the total design load. Compare this against the component’s capacity from data sheets or standards.

Tip: If the total exceeds capacity, identify which loads contribute most and consider redesign. - 6

Document assumptions and results

Prepare a clean, auditable report including inputs, formulas, results, and decisions. Include diagrams if helpful.

Tip: Include a section for sensitivity analysis to show robustness. - 7

Review and obtain approval

Have a qualified peer review the calculations and sign off before application or construction.

Tip: Schedule periodic re-evaluations when configurations change.

Quick Answers

What is meant by 'load capacity'?

Load capacity is the maximum load a component can safely carry under defined conditions, accounting for static and dynamic effects and safety margins. It is limited by material properties and design standards.

Load capacity is the maximum safe load a component can carry, considering safety margins and design standards.

Why do I need to calculate load capacity?

Calculating load capacity helps prevent structural failure, equipment damage, and safety incidents by ensuring loads stay within safe limits and margins.

You calculate it to prevent failures and keep operations safe and compliant.

What units should I use?

Use consistent units throughout the calculation, such as Newtons or pounds. Convert all inputs to the chosen unit before summing.

Stick to the same units across all inputs and convert as needed.

How do safety factors affect the calculation?

Safety factors reduce the allowable load to account for uncertainties and variability. Higher factors result in smaller allowable loads, increasing margin.

Safety factors lower the allowable load to cover uncertainties.

Can I reuse data from one component for another?

Only if the components share identical materials, geometry, and operating conditions. Otherwise re-evaluate with updated data.

Only reuse data if the conditions are truly identical.

How often should I update load capacity calculations?

Update whenever configurations change, new equipment is added, or standards are revised. Regular reviews help maintain accuracy.

Update when things change or standards update.

Watch Video

Top Takeaways

- Define scope and inputs before calculation.

- Use consistent units and sources.

- Compare total factored load to capacity data.

- Document assumptions and data sources.

- Verify results with peer review and sensitivity checks.