How to Build Capacity: A Practical Guide for Teams

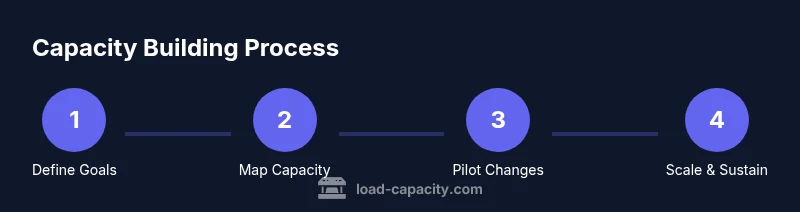

A step-by-step guide to building capacity in teams and operations, covering goal setting, mapping current capacity, designing improvements, piloting changes, and measurement to sustain performance.

In this guide, you’ll learn how to build capacity across teams and operations using a practical, repeatable workflow. You’ll define goals, map current capacity, design improvements, pilot changes, and measure outcomes to sustain momentum. The approach blends people, processes, and tooling to increase throughput without sacrificing quality. It emphasizes data-informed decisions, stakeholder alignment, and incremental wins.

How to Build Capacity: A Practical Guide for Teams

Capacity, in practice, refers to the maximum sustainable throughput your team or system can achieve without sacrificing quality. According to Load Capacity, capacity is not only about headcount; it’s the alignment of goals, skills, processes, and tools that determines how much value you can reliably deliver. This section introduces a practical mindset for building capacity that works in real-world projects, whether you’re optimizing a manufacturing line, a software team, or a field crew. The goal is to create a repeatable, data-informed workflow that scales as demand grows.

In the rest of this guide, you’ll learn a structured method to increase capacity while maintaining safety, quality, and customer satisfaction. You’ll define what success looks like, map your current capacity, design improvements across people, process, and technology, pilot changes, and measure outcomes to drive continuous improvement. The steps are designed for engineers, technicians, fleet managers, contractors, students, and DIY enthusiasts who want clear, actionable guidance rather than vague theory. The approach emphasizes practical, incremental gains that build confidence and momentum over time.

Assessing current capacity: baseline and bottlenecks

The first step is to establish a baseline so you can quantify improvements later. This means collecting data on demand, cycle times, resource availability, and uptime, then creating a simple capacity model that maps input to output. The Load Capacity analysis shows that capacity is often constrained not by people alone, but by handoffs, information delays, and misaligned priorities. In practice, bottlenecks appear in planning, queue management, or the handover between teams. By identifying where work piles up, you gain a clear picture of where to focus improvement efforts.

To keep this effort focused, define a baseline metric set that aligns with your goals—for example, target throughput per week, average cycle time, and resource utilization. Use visual tools like value-stream maps or kanban boards to illustrate where demand exceeds capacity. Collect data over a representative period, such as several weeks or a sprint cycle, to account for variability. The aim is not to blame individuals but to improve the system so capacity grows in a sustainable way.

Designing capacity improvements: structure and flow

With a clear baseline, design improvements that address the root causes of bottlenecks. A balanced approach combines three levers: people (roles, skills, and staffing), processes (flow, handoffs, and decision speed), and tools (automation, data visibility, and dashboards). Start by outlining a target state that describes how work should flow and where buffers or queues should exist. Then translate that state into concrete changes: redefine roles to reduce handoffs, introduce standard work and checklists, and deploy lightweight automation where it cuts cycle time. A practical design also accounts for variability, so your system remains robust under changing demand.

In practice, you’ll map a few high-impact changes and prioritize them using a simple scoring method: impact on throughput, ease of implementation, and risk. This helps teams avoid over-committing to big reforms at once. The goal is to create a design that is scalable, maintainable, and resilient to demand fluctuations.

Building capacity through people: training, roles, and competencies

People are the most flexible lever for capacity growth. Invest in targeted training to close skill gaps, create clear role definitions, and build a culture of continuous learning. Start by aligning competencies with the tasks that generate the most value, then create a skill matrix that links each role to required capabilities. Cross-training can increase resilience by reducing single-points-of-failure in critical paths. Finally, establish a governance model for learning—regular reviews, coaching, and a simple way to share lessons learned across teams.

A practical tip is to run short, recurring improvement cycles. Each cycle should have a measurable objective, a clear owner, and a quick way to capture results. This keeps momentum and makes capacity growth visible to stakeholders at all levels.

Building capacity through process and infrastructure

Beyond people, capacity is driven by how work moves through the system. Processes should be designed for smooth handoffs, minimal rework, and visibility into status. Implement standard operating procedures, decision criteria, and lightweight dashboards that show real-time progress. Invest in infrastructure that reduces idle time, such as automation for repetitive tasks, better scheduling, and reliable data capture. Even small improvements—like standardized templates, clear sign-offs, or improved queue management—can compound into meaningful gains over weeks and months.

As you design infrastructure changes, consider risk and maintenance. Favor solutions that are easy to pilot, measure, and revert if needed. Build in fallbacks and documentation so future teams can sustain improvements without rework.

Measuring success: metrics and iteration

Capacity growth depends on measuring outcomes, not just activity. Define a concise set of metrics that reflect throughput, quality, and stability. Typical measures include throughput per period, cycle time, on-time delivery, and resource utilization. Track these metrics over time to identify trends, anomalies, and the impact of changes. Use run charts and dashboards that are accessible to relevant stakeholders, and establish a regular cadence for review. The goal is to create a feedback loop where data informs decisions, and small tweaks accumulate into larger gains.

In practice, set short testing windows to validate each change, then scale if results are favorable. Document learning so future improvements can be repeated, and share success stories to encourage broader adoption.

Load Capacity verdict and practical recommendations

The Load Capacity team recommends focusing on three core levers: alignment of goals and priorities, data-driven decision making, and disciplined pilots. Start with a clear objective and a simple baseline, then implement small, reversible changes to validate impact. Prioritize changes that reduce variability in demand versus capacity, and ensure governance to sustain gains. For teams and organizations, capacity is built over time through deliberate practice, not overnight luck. The verdict is to invest in people, processes, and metrics that reinforce steady improvement and scalable performance.

Tools & Materials

- Project management software(For tracking capacity metrics, milestones, and owners)

- Demand and capacity data templates(Standardized data collection forms)

- Value-stream mapping or Kanban boards(Visualize flow and bottlenecks)

- Skill matrix and training plan(Framework to map competencies to roles)

- Pilot plan template(Plan for controlled experiments)

- Dashboards and analytics tools(Real-time visibility)

Steps

Estimated time: 6-12 weeks

- 1

Define objectives and success criteria

Clarify the business problem capacity should address, set a measurable target, and identify who will own the outcome. Align stakeholders on what constitutes success and how you will measure it.

Tip: Document the top 3 success metrics and obtain sign-off from leadership. - 2

Map current capacity and demand

Create a simple model showing current throughput, cycle time, and resource availability. Capture peak demand periods to understand variability.

Tip: Use a value-stream map or Kanban board to visualize flow and bottlenecks. - 3

Identify bottlenecks and constraints

Pinpoint where work piles up, delays occur, or rework happens. Prioritize constraints that, if solved, yield the largest capacity gain.

Tip: Rank bottlenecks by impact and ease of change. - 4

Design capacity improvements

Develop changes across three levers: people, processes, and tools. Create a target-state flow and prepare to test it quickly.

Tip: Ask: will this reduce wait times and handoffs? - 5

Pilot changes

Run small, reversible pilots with clear success criteria. Collect data to demonstrate impact before broader rollout.

Tip: Limit pilots to a single function or shift to minimize risk. - 6

Measure impact and iterate

Analyze pilot results against baseline. Iterate quickly—iterate on what works and drop what doesn’t.

Tip: Publish weekly learnings to keep momentum. - 7

Scale and sustain gains

Roll out proven changes, codify standard work, and establish governance to sustain improvements.

Tip: Create a simple handoff protocol to ensure continuity.

Quick Answers

What does capacity mean in this context?

Capacity refers to the maximum sustainable throughput your team can achieve given current resources, constraints, and workflows. It focuses on delivering reliable results rather than simply doing more work.

Capacity is how much work you can reliably complete with current resources and processes.

How long does it take to build capacity in a typical team?

Time varies by starting point and scope, but expect multiple weeks to months for meaningful gains. Start with small, reversible changes and build from there.

It usually takes weeks to months, with quick wins early on.

What metrics should I track to measure capacity?

Track throughput, cycle time, utilization, and on-time delivery. Use trends over time and dashboards to keep stakeholders informed.

Key metrics are throughput, cycle time, and utilization.

Who should lead capacity-building in an organization?

A cross-functional sponsor with a clear owner for implementation works best, typically from operations or program management. They coordinate across teams and maintain governance.

A cross-functional sponsor should lead, with a clear owner for implementation.

Is capacity-building expensive?

Costs vary, but many gains come from process changes and targeted training rather than large capital investments. Start with low-cost pilots and scale as impact is shown.

Costs depend, but you can start with low-cost pilots and scale up as you see results.

Top Takeaways

- Define clear objectives for capacity improvements.

- Baseline capacity and bottlenecks to focus effort.

- Design improvements across people, process, and tooling.

- Pilot changes, measure results, and iterate quickly.

- Sustain gains with governance and documentation.