Armoured Cable Size and Load Capacity: A Practical Sizing Guide

Comprehensive guidance on armoured cable size and load capacity, including sizing principles, standards, workflow, and practical examples for safe electrical installations.

Armoured cable size and load capacity are linked through current rating and voltage. Proper sizing depends on installation method, ambient temperature, insulation, and protective devices, not on a single number. The key takeaway: select a cable size that safely carries the expected load within applicable codes, using a structured sizing workflow to ensure safety, efficiency, and long-term reliability.

Understanding armoured cable size and load capacity

Armoured cable size and load capacity are not arbitrary numbers carved from thin air; they are the practical outcome of engineering judgment, standards, and site conditions. For engineers, technicians, and project managers, the task is to ensure the chosen armour cable size can reliably carry the intended load without overheating, nuisance tripping, or equipment damage. The relationship between size and load capacity is influenced by temperature rise, insulation type, and how the cable is installed. According to Load Capacity, you should start with the expected continuous load and then factor in peak demands, diversity, and protection strategy to arrive at a size that remains within the thermal and current-rating limits of the chosen conductor and insulation system.

In many jurisdictions, the sizing process begins with a conservative first guess, followed by checks against local codes and manufacturer data. Armoured cables offer robust physical protection, which is essential in exposed installations, outdoor runs, or areas with physical hazards. However, this protection comes with a trade-off: larger diameter cables can be stiffer, heavier, and more expensive. The goal is to balance mechanical protection with electrical performance, ensuring that the armoured cable size and load capacity meet safety targets while remaining cost-effective.

Regulatory context and standards governing armoured cable sizing

Sizing armoured cable correctly requires adherence to recognized standards, codes, and local regulations. The most influential frameworks address conductor material, insulation, sheath properties, and how the assembly interfaces with protection devices and fault-clearing mechanisms. In many regions, the selection process depends on a combination of international standards and national codes. TheLoad Capacity team emphasizes that following established guidelines minimizes risk and helps ensure compatibility with protective devices, terminations, and enclosures. When in doubt, consulting IEC series standards and the national electrical code relevant to your jurisdiction provides a solid foundation for determining armoured cable size and load capacity. Moreover, manufacturers often publish installation manuals that translate standards into practical tables and calculators tailored to specific materials and jacketings.

For safety-critical environments—such as industrial facilities, hospitals, or high-humidity locations—more stringent derivations are used. These environments may require derating factors for temperature, grouping, and ambient conditions. Load Capacity’s methodology recommends documenting all derating assumptions and auditing them against the project’s operating conditions. This disciplined approach helps maintain the integrity of the armoured cable size and load capacity throughout the life of the installation.

Key factors that influence load capacity in armoured cables

Several variables determine the effective load capacity of an armoured cable:

- Temperature and thermal environment: The maximum current rating is a function of ambient temperature and the insulation’s thermal resistance. Higher temperatures lower the allowable current, which can affect the chosen size if derating is required.

- Installation method: Cables in conduit, ducts, or trays experience different cooling conditions. Constrained runs with poor air flow typically require smaller loads to avoid overheating, while open-air or well-ventilated routes can support higher loads for the same conductor size.

- Bundling and proximity: When multiple cables run together, heat build-up increases, necessitating derating. The degree of derating depends on spacing and the number of operated circuits in proximity.

- Material and construction: Copper conductors, insulation type, and armour material affect resistance, voltage drop, and temperature rise. Armour adds mechanical safety but can influence heat dissipation.

- Protection and terminations: Correct fusing, circuit breakers, and protective devices ensure rapid disconnection in fault conditions, indirectly influencing the acceptable continuous load by enforcing short-circuit protection.

Understanding these factors helps engineers quantify how a given armoured cable size will perform under real-world conditions, supporting a more accurate load-capacity assessment.

Sizing workflow: a practical step-by-step approach to armoured cable size and load capacity

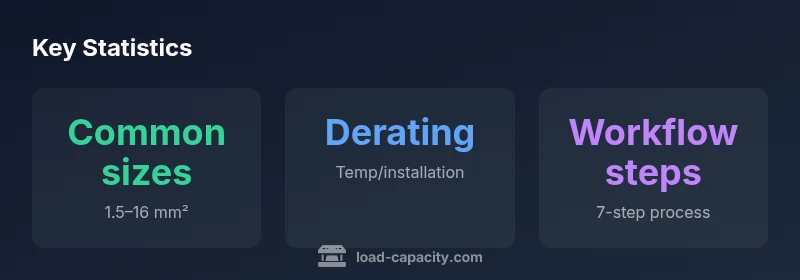

Follow a structured workflow to determine the appropriate armoured cable size and load capacity:

- Define electrical parameters: Identify nominal voltage, phase configuration, and expected continuous load. Document any diversity factors and future expansion needs.

- Establish protection criteria: Determine the protective devices (fuse or breaker) and their trip curves. Ensure coordination with the load profile.

- Apply temperature derating: Review the ambient temperature and installation method to compute the derating factor for current capacity.

- Select an initial cable size: Choose a standard armoured cable size that exceeds the derated load, keeping voltage drop within acceptable limits.

- Verify mechanical constraints: Confirm that the armour and overall diameter fit the conduit or tray routing and that bending radii are within specifications.

- Cross-check with standards and manufacturer data: Compare against IEC/National codes and the supplier’s ampacity tables for the chosen insulation and armouring.

- Document reserves and contingencies: Include margins for short-term peaks and aging effects; re-run calculations if circuit loads change.

This step-by-step approach embodies the principle that armoured cable size and load capacity should be derived from a disciplined process rather than guesswork, ensuring safety and reliability across the life of the installation.

Common sizes and practical examples

Understanding representative sizes helps with quick planning and procurement. The following examples illustrate how armoured cables are commonly chosen for different load scenarios. These examples are qualitative summaries, emphasizing how size selection changes with load, rather than presenting precise ampacity figures. Always consult up-to-date manufacturer data and local codes when finalizing a design. The goal is to match the cable size and load capacity to the actual demand, with appropriate derating for temperature and grouping.

- Small residential lighting and accessory circuits: relatively small armoured sizes are typical, chosen to support steady loads without excessive voltage drop.

- General power outlets and kitchen circuits: larger sizes provide margin for startup surges and higher sustained loads.

- Industrial or outdoor circuits: larger armoured sizes are selected to accommodate higher current, environmental exposure, and mechanical protection.

In every case, you should compare the final selection against a formal derating calculation and the relevant standard tables to confirm compliance. The emphasis remains on ensuring that armoured cable size and load capacity are aligned with safety requirements, code adherence, and the practical realities of the installation environment.

Practical considerations: temperature, derating, and fault protection

As you translate armoured cable size into a final load-capacity figure, several practical considerations come into play. Temperature ratings, insulation classes, and the armour type interact to set the real-world current-carrying capability. Derating is essential in crowded cable bundles or hot environments, and it must be documented and justified. Fault protection is not a decorative accessory: breakers, fuses, and proper termination arrangements must be designed to interrupt current quickly and safely, which in turn legitimizes the chosen cable size under fault conditions. Finally, verify that mechanical installation details—such as tray spacing, clamp types, and support intervals—do not undermine thermal performance. A holistic approach ensures that armoured cable size and load capacity translate into durable, safe operation over the system’s lifetime.

Representative armoured cable sizes and typical applications

| Cable Size (mm²) | Typical Applications | Notes |

|---|---|---|

| 1.5 | Lighting and small power | Common interior runs; limited current |

| 2.5 | General outlets | Moderate current; common in living spaces |

| 4 | Higher-demand circuits | Kitchen outlets and larger loads |

Quick Answers

What is armoured cable, and where is it typically used?

Armoured cable features a protective outer layer to resist mechanical damage. It’s commonly used in exposed installations, outdoor runs, and spaces where physical protection and durability are essential. The armour can influence heat dissipation, so sizing must account for installation conditions.

Armoured cable has a protective outer layer for durability, used where physical damage is a risk. Sizing considers installation conditions and heat dissipation.

How do I calculate load capacity for armoured cable?

Begin with the expected continuous load, account for diversity and peaks, then apply temperature and installation derating. Use standard tables and manufacturer data to confirm the final size, and verify with protective device coordination.

Start with the load, apply derating for temperature and installation, then check against manufacturer tables.

Does ambient temperature affect load capacity?

Yes. Higher ambient temperatures reduce the allowable current, so derating is often required for cable runs in hot environments or in bundles.

Temperature reduces how much current a cable can safely carry, so you may need to derate.

Can I oversize a cable to be safe?

Oversizing can provide voltage drop and future-proofing benefits, but it increases cost and installation complexity. It’s best to size for current needs with margin rather than oversize excessively.

Oversizing wastes money and space; size for current needs with a safe margin.

Which standards govern armoured cable sizing?

Standards vary by region but typically involve IEC series and national codes or regulations. These standards guide conductors, insulation, armour, and circuit protection practices.

IEC standards and local codes guide how you size armoured cables.

Where can I find reliable tables or calculators?

Consult manufacturer installation manuals, accredited standards bodies, and recognized electrical-safety organizations. Use official tables and calculators provided by manufacturers and standardization bodies.

Look up manufacturer and standards-body tables and calculators for trusted guidance.

“Sizing armoured cable size and load capacity requires a methodical approach that balances safety, cost, and performance. When in doubt, follow standard guidance and verify with testing.”

Top Takeaways

- Assess load with a documented method and apply derating for temperature

- Choose a standard armour size that provides safety margins and code compliance

- Factor installation method and grouping into the sizing decision

- Verify with manufacturer data and local standards before finalizing

- Document all assumptions and future expansion plans