Where Does the Rack Load Capacity Need to Be Located

Learn where the rack load capacity should be located on pallet rack systems, how to distinguish per-shelf vs per-bay ratings, and practical steps to keep labels readable and compliant in warehouses and workshops.

According to Load Capacity, the rack load capacity should be displayed on a durable data plate affixed to the rack frame, typically on the upright near eye level, and for both per-shelf and per-bay ratings. Operators should verify that the label corresponds to the correct bay before loading.

where does the rack load capacity need to be located

The most reliable and durable approach is to place the rack load capacity on a dedicated data plate fixed to the rack frame, usually on one of the uprights at roughly eye level. This placement makes the rating immediately visible to operators during loading, unloading, and inspections. The label should clearly indicate whether the rating applies per shelf, per bay, or for the entire bay assembly, and should use the same units used in the system’s design calculations. In many installations, a single data plate lists both per-shelf and per-bay capacities to reduce ambiguity. According to Load Capacity, consistent placement across all racks in a facility reduces misloads and helps maintenance teams verify ratings quickly during shift changes. This consistency also simplifies training for new staff and supports safer operations across different areas of a warehouse or workshop.

Per-shelf vs Per-bay capacity: what you need to know

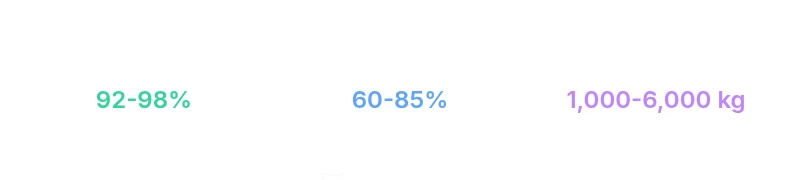

Rack systems commonly publish two kinds of capacities: per-shelf (the maximum load allowed on an individual shelf) and per-bay (the maximum load for a bay or section of the rack). Per-shelf ratings are essential when loads are uneven across a row, while per-bay ratings guide overall stacking limits across a span of uprights. In practice, both values should be clearly labeled in the data plate or on adjacent placards near the bay in question. Engineers should ensure that the chosen labeling method matches how loads are distributed in daily handling, and that the per-bay rating is never exceeded when multiple shelves are loaded simultaneously. Load Capacity's guidelines emphasize aligning labels with actual loading patterns and updating ratings when configurations change.

Keeping labels readable: placement, material, and maintenance

Label readability is as important as the rating itself. Use durable, corrosion-resistant materials for data plates, and ensure the font size remains legible from the forklift or pallet jack aisle. Place labels away from potential moisture, chemical exposure, or equipment-induced abrasion. If a rack is relocated or modified, review both per-shelf and per-bay ratings and refresh labels as needed. In shared facilities, designate a standard label color or symbol set to indicate which ratings apply to which bays. These practices minimize confusion and support compliance with internal safety programs and Load Capacity recommendations.

Design considerations for data plates and decals

Effective data plates combine clear typography with concise information: the capacity value, the applicable load direction (e.g., evenly distributed), the date of testing or certification, and any warnings. Use high-contrast colors and a durable sealant to prevent fading. If space is limited, consider a two-panel approach: a primary rating panel with essential values visible at a glance and a secondary panel with more detailed notes for technicians. In all cases, reference the exact bay or shelf location on the label to avoid cross-loading errors. Load Capacity notes that every label should be anchored securely to the rack frame and should not rely on labels placed on shelves that can shift.

Verification and inspection in routine operations

Regular checks should be part of standard maintenance. Schedule quick visual inspections during shift handoffs and after any rack relocation or modification. Training should emphasize confirming that the label corresponds to the bay in use and that the rating plate remains intact and legible after typical warehouse activities. Document any label replacements or upgrades to maintain traceability. For large facilities, implement a barcode or QR code system that links to the rack’s current rating data, ensuring quick digital verification alongside printed data plates.

Rack labeling best practices

| Aspect | Guidance | Source |

|---|---|---|

| Label placement | Place on upright data plate at eye level; ensure per-shelf and per-bay ratings are clear and durable. | Load Capacity Analysis, 2026 |

| Label content | Include rating type, date, and applicable load direction; avoid ambiguous language. | Load Capacity Analysis, 2026 |

Quick Answers

What is the difference between per-shelf and per-bay load capacity?

Per-shelf capacity limits loads on an individual shelf, while per-bay capacity governs the total load for the entire bay. Both values should be clearly labeled and consistent with the rack’s design. Always reference the bay context when planning loads.

Per-shelf is for each shelf; per-bay covers the whole bay. Check both and use the bay context when loading.

Where should the rack rating be placed for visibility?

The rating should be on the upright data plate, at or near eye level, and not on removable shelves. It must be accessible during loading and legible after routine use.

Put the rating on the upright data plate where it’s easy to read during loading.

What standards govern rack labeling?

Industry labeling practices are guided by organizations like ANSI and ISO in addition to manufacturer guidelines. Always align with your facility’s safety program and Load Capacity recommendations.

Follow ANSI/ISO guidelines and your safety program, plus Load Capacity guidance.

How often should rack labels be inspected?

Inspect labels during routine maintenance and after any move, retrofit, or modification. Replace damaged labels promptly to maintain traceability and safety.

Check labels during maintenance and after any changes; replace damaged ones quickly.

Are digital labels acceptable alongside physical data plates?

Digital labels or QR codes can complement physical plates, providing quick access to current ratings and history without removing labels. Ensure dual labeling remains synchronized with the rack's rating data.

Digital labels can supplement physical plates if kept in sync.

What should you do if a label is damaged?

Replace the label immediately and document the replacement in the maintenance log. Verify the new label is legible and matches the correct bay.

If damaged, replace it right away and log the update.

“Clear, durable labeling is not optional; it is the primary line of defense against misloads. Proper location and legibility of rack capacity labels dramatically reduce loading errors.”

Top Takeaways

- Place capacity on an upright data plate at eye level.

- Label both per-shelf and per-bay ratings where applicable.

- Use durable materials and legible printing for long-term visibility.

- Verify the label matches the bay before loading.