How to Increase Floor Load Capacity: A Step-by-Step Guide

Learn proven methods to increase floor load capacity safely—from assessment and load-path analysis to reinforcement options and code compliance. This guide provides step-by-step strategies, tools, and considerations for engineers, technicians, and builders.

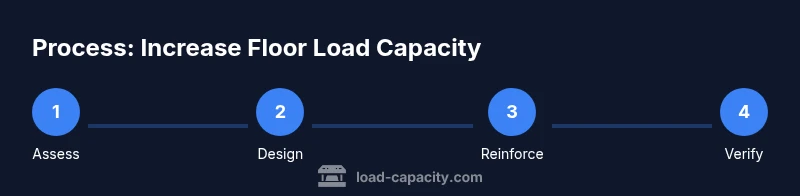

Increase floor load capacity by confirming existing capacity with a licensed engineer, selecting a reinforced plan, and executing it under code-compliant designs. For a complete sequence of actions, see the full step-by-step guide.

Why floor load capacity matters

According to Load Capacity, floor load capacity is a fundamental limit that determines how much weight a floor system can safely carry without risk of structural failure or excessive deflection. Understanding this limit is essential for designers, builders, and facility managers who must accommodate equipment, stored materials, or occupant loads. In practice, floors are part of an interconnected system consisting of joists, beams, columns, and subflooring; increasing capacity requires a holistic view of all these components and how loads travel through them.

The consequences of underestimating floor loads include cracked slabs, sagging floors, misaligned doors, and even wall and column failures under extreme events. By contrast, properly engineered upgrades can yield safer buildings, longer service life, and the ability to repurpose spaces with confidence. This article focuses on how to increase floor load capacity with a disciplined process that begins with measurement and ends with verification. Load Capacity's team emphasizes safety, thorough documentation, and code compliance as non-negotiable parts of any reinforcement plan.

Assessing existing capacity: measuring, mapping, and documenting

Begin with a field survey to map the current structure: identify floor area, joist size and spacing, subfloor thickness, and any existing reinforcement. Record dimensions, connections, and signs of distress. If structural drawings exist, compare them with the as-built reality. Use tools like measuring tapes, laser levels, and stud finders to locate joists and support members. Note door thresholds and slab edges that might constrain load redistribution.

Next, determine the current capacity using a conservative approach: treat each floor bay as a separate tributary area and estimate live load plus dead load. Use manufacturer data for installed equipment and fixtures, and account for dynamic loads that move or vibrate, such as forklifts, carts, or dense shelving. Where uncertainty remains, escalate to a licensed structural engineer who can provide load ratings, factor-of-safety, and recommended limits for modifications. Documentation matters: keep sketches, photos, and draw-ready notes to guide subsequent design decisions.

Load paths and distribution: how loads travel through a floor

A floor transfers weight through a series of connected members, and loads are not evenly distributed. Tributary areas defined by joist spacing and beam locations determine the portion of total load each member carries. Slow, gradual deflection can hide critical weaknesses, so visual cues like springy floors or cracking near joists should be investigated. Build your understanding around the concept of load path: where does the weight begin, how does it move through joists, beams, and columns, and where does it exit the system?

In practice, you’ll often find that heavy equipment creates concentrated points of stress. By redistributing loads—adding supports along critical spans, using load-spreading plates, or adjusting equipment layout—you can raise the effective floor capacity without a full structural rebuild. However, any redistribution plan must be validated with calculations and code-compliant detailing to ensure it won’t transfer risk to adjacent members or deflections that compromise serviceability.

Structural reinforcement options: upgrading framing

There are several proven approaches to strengthening a floor system, each with trade-offs in cost, disruption, and effectiveness. Common strategies include sistering or doubling up undersized joists to restore stiffness; replacing single members with higher-capacity sections; adding additional joists to reduce tributary areas; and installing temporary or permanent support posts beneath sagging spans.

For long spans or heavily loaded areas, professionals may specify steel beams or reinforced concrete caps, especially where wood alone cannot achieve required capacity. When selecting a path, consider compatibility with existing materials, attachment methods, fire resistance, and vibration criteria. All reinforcement schemes should be designed by a licensed engineer and documented with drawings, connection details, and required clearances. A well-designed plan minimizes disruption and ensures a predictable improvement in capacity rather than a patchwork solution.

Subflooring and decking improvements

Upgrading the subfloor or decking can meaningfully affect floor stiffness and capacity, particularly when used in combination with framing reinforcement. Options include using thicker plywood or OSB, adding an additional layer of subfloor, or upgrading fasteners to longer, high-profile nails or screws. Pay attention to moisture control, as excessive humidity can degrade fastener performance and wood strength. In some cases, bridging or cross-bracing beneath panels helps distribute loads more evenly.

If you’re replacing or stiffening the surface, ensure compatibility with floor finishes and existing trim. Subfloor improvements can be simpler and cheaper than major framing work, but they must still be coordinated with structural changes and approved by the engineer. Always verify that increased stiffness from decking enhancements aligns with new load ratings in the final design.

Material choices and compatibility: wood, steel, and concrete

Choosing reinforcement material is not only about strength but also about compatibility with existing members. Wood components are often easiest to modify on interior spaces but may require fastener upgrades and moisture control. Steel offers high strength-to-weight and can be effective in retrofits, but it demands careful connections, fireproofing, and precise alignment. Concrete or composite systems may be used for slabs or floor-on-grade upgrades, but they introduce heavier loads and require foundations or footings.

Engineers will consider stiffness (EI), shear capacity, ductility, and long-term performance under cyclic loads. The right combination of materials depends on existing framing, occupancy, and the required performance. In all cases, ensure the new details are integrated into a unified design package with proper detailing for joints, fasteners, and spacings.

Non-structural strategies to redistribute loads

If a full structural upgrade isn’t feasible, non-structural changes can help you operate safely within existing limits while still increasing usable capacity. For example, reconfigure storage and equipment layouts to shift heavy items toward structurally stronger bays, install load-distributing mats or plinths under heavy machinery, and use vibration isolation to reduce peak loads transmitted to framing. Educate staff about weight limits and provide clear signage to prevent accidental overloading. Keep a living plan: update it whenever you change the layout or add new equipment.

Remember: non-structural changes should complement, not replace, structural reinforcement. They may help you meet short-term goals but won’t eliminate structural risk if the underlying capacity remains insufficient. Always verify modifications with the engineer’s guidance and keep documentation up to date.

Calculations, codes, and verification: how to prove increased capacity

Engineering calculations are essential to justify any capacity increase. The design team uses load ratings for each member, calculations for combined dead and live loads, and safety factors consistent with the applicable code. Engineers translate these ratings into allowable loads for bays, spans, and connections, and they specify required reinforcements, attachments, and inspection criteria. It’s important to work with your local building department to determine which permits are required and whether third-party inspections are necessary.

Code references will vary by jurisdiction, but typical standards address framing, fasteners, fire resistance, vibrations, and load combinations. Documentation should include revised drawings, material specifications, and testing or verification plans. In many cases, a professional engineer’s seal is required for permit approval, and the final report should summarize expected capacity gains, construction details, and maintenance recommendations.

Implementation plan: phased reinforcement and permitting

A phased plan reduces disruption and improves safety. Phase one concentrates on securing the site, finalizing calculations, and obtaining permits. Phase two covers the actual reinforcement work, with sequential installation to avoid overstressing any single member. Phase three conducts a thorough inspection and testing to validate performance. If the project is in a sensitive area (eg, occupied space or sensitive equipment), set up temporary supports and clear boundaries to protect people and assets.

Schedule coordination is critical: align trades to minimize downtime, coordinate utility shutdowns if necessary, and conduct safety briefings before each phase. The engineer should oversee critical steps, approve temporary supports, and verify connections and tolerances. Documentation should track every change, including as-built drawings and any deviations from the original plan.

Maintenance, monitoring, and long-term safety

After reinforcing floor capacity, establish a monitoring program to detect deflection, drift, and fastener loosening. Schedule periodic visual inspections and, if feasible, instrumental monitoring for critical spans. Establish a maintenance plan for coatings, corrosion protection, and rust prevention. Keep the structural documentation current and re-run capacity checks whenever you modify or load the floor again. A proactive approach to maintenance extends service life and reduces the risk of unexpected failures.

If your space changes use-case or loading patterns, revisit the reinforcement strategy with your structural engineer. The Load Capacity team recommends annual reviews of floor loads and a 5–10 year refresh of documentation to ensure continued safety and performance.

Tools & Materials

- Measuring tape(At least 25 ft; for long bays, use 30–50 ft for efficiency)

- Laser level(To verify flatness and detect deflection across spans)

- Stud finder(Locate joists, studs, and supporting members accurately)

- Carpenter’s square(Check perpendicularity and joint alignments)

- Chalk line and markers(Mark layouts, cut lines, and reference points)

- Drill/driver with wood and metal bits(Install fasteners and anchor plates securely)

- Saw (circular/reciprocating)(On-site cutting for new members or spacers)

- Safety gear(Hard hat, eye protection, gloves, hearing protection)

- Level and straightedge(Confirm elevations and alignment daily)

- Structural engineer consultation(Obtain design, load calculations, and approvals)

Steps

Estimated time: 6-12 weeks

- 1

Engage a structural engineer

Hire a licensed structural engineer to assess existing capacity, review drawings, and prepare a code-compliant reinforcement plan. This establishes the design basis and reduces risk of over- or under-strength solutions.

Tip: Have site drawings ready and list all equipment that could affect loads. - 2

Inventory and measure framing

Document joist sizes, spacing, subfloor thickness, connections, and any signs of distress. Use the tools listed to verify dimensions and create accurate as-built records.

Tip: Capture photos and label critical connections for easy reference. - 3

Develop reinforcement strategy

With the engineer, select a feasible reinforcement path (e.g., sistering, adding joists, or beams) and outline connection details, tolerances, and fire-safety considerations.

Tip: Prefer designs that minimize disruption while maximizing stiffness across critical spans. - 4

Prepare drawings and permit package

Translate the chosen reinforcement path into drawings and specifications. Submit for permits and coordinate inspections with the local authority having jurisdiction.

Tip: Include temporary support plans and load-control measures to protect occupants. - 5

Implement reinforcement work

Carry out the reinforcement work according to the approved drawings, ensuring all connections are tight, and loads are redistributed as planned.

Tip: Stagger work to avoid overstressing remaining members during retrofit. - 6

Verify performance and finalize documentation

Perform post-installation checks for deflection, connections, and alignment. Compile as-built drawings, final load ratings, and maintenance recommendations.

Tip: Schedule a follow-up inspection after a conditioning period (e.g., 2–4 weeks).

Quick Answers

What is floor load capacity and why does it matter?

Floor load capacity is the maximum weight a floor system can safely support without excessive deflection or failure. It matters for equipment, storage, and occupancy; exceeding it can cause structural damage and safety risks.

Floor load capacity is the maximum safe weight for a floor. Avoid overloading and consult a professional when planning moves or additions.

Can I increase floor load capacity without replacing joists?

Yes, through methods like sistering, adding additional joists, or installing load-distributing elements and cap supports. A licensed engineer determines the best option and ensures compatibility with existing framing.

You can boost capacity with reinforcements, but you’ll need an engineer to confirm the right approach.

What permits are typically required for reinforcement projects?

Permits depend on local codes. Most projects involving structural changes require review and approval from the building department and inspections by qualified professionals.

Most structural upgrades need permits. Check with your local authority to avoid compliance issues.

How long does a floor reinforcement project typically take?

Duration varies with scope, but a typical reinforcement project spans several weeks to a few months, depending on complexity, accessibility, and whether temporary supports are used.

It usually takes weeks to a few months, based on how extensive the reinforcement is.

What costs are involved in increasing floor load capacity?

Costs depend on scope, materials, and labor. Expect estimates to cover engineering, permitting, materials, and contractors, with contingency for site-specific challenges.

Costs vary; work with your engineer to get a clear, written estimate before approving plans.

Is floor load capacity different for concrete floors?

Yes, concrete floors have different behavior and reinforcement options than wood-framed floors. A structural engineer accounts for concrete strength, slab thickness, and joint details in capacity calculations.

Concrete floors behave differently; consult an engineer for concrete-specific reinforcement details.

Watch Video

Top Takeaways

- Get engineer approval first

- Assess current capacity and load paths

- Choose a compatible reinforcement path

- Verify gains with calculations and codes