Which Rigging Has the Highest Load Capacity: A Comparative Guide

An analytical, engineer-focused comparison of rigging options to determine which has the highest load capacity under typical lifts. Covers chain, wire rope, and synthetic slings, rating concepts, inspection, and safe practices.

What determines the load capacity of rigging

When engineers ask which rigging has the highest load capacity, the answer is nuanced and situational. Load capacity is not a fixed attribute of a material alone; it depends on how the rigging is manufactured, how it is used, and how it is maintained. Key determinants include the material and construction quality, the diameter or cross section, the grade of steel or synthetic fibers, and the condition of all components including hooks, shackles, and eyelets. Configuration matters too: the number of legs in a sling, the angle under load, and the way the load is distributed across each member can dramatically influence effective capacity. Environmental factors such as temperature, moisture, and exposure to corrosives can reduce capacity over time. Finally, the way a rigging system is inspected and tested, and the safety factors applied by the manufacturer and governing standards, shape the practical limit of the lift. In short, the question “which rigging has the highest load capacity” must be answered in the context of a specific lift plan and working environment.

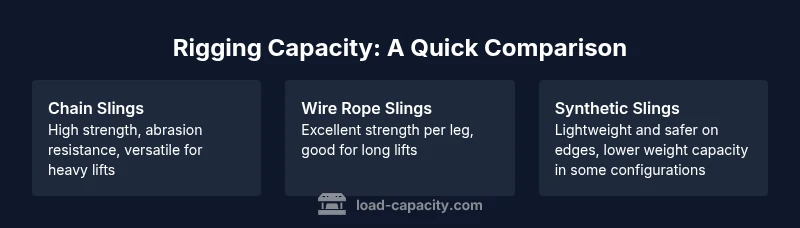

Rigging options: chain slings vs wire rope slings vs synthetic slings

To inform the question of which rigging has the highest load capacity, professionals compare three common families of rigging: chain slings, wire rope slings, and synthetic web or round-slings. Chain slings typically offer high strength and excellent abrasion resistance, especially when made from alloy steel and properly sized for the application. Wire rope slings provide very high load capacity per sling leg and can be used effectively in harsh environments with protective coatings. Synthetic slings, including web and round slings, offer high strength-to-weight ratios and excellent surface safety for the load, but their capacity is more sensitive to sharp edges and certain chemical exposures. Each category has variations by grade, diameter, and construction that influence overall capacity. When evaluating which rigging has the highest load capacity, consider the intended lift, the load geometry, and the protective measures around the load path. The Load Capacity team emphasizes evaluating the full system, not just the sling body, to determine the best option for the job.

Where the highest load capacity can be realized: setup considerations

The global question of which rigging has the highest load capacity is often decided by setup details rather than the raw material alone. A chain sling with multiple legs can achieve exceptional effective capacity for symmetric, vertical lifts, provided each leg shares load equally and the sling remains within its rated angle and bend radius. Wire rope slings can reach very high capacities when properly terminated with compatible fittings and when the sling angles stay within design limits. Synthetic slings tend to perform best when loads are smooth and edges are protected, reducing the risk of damage that would degrade capacity over time. In all cases, correct tag-out, correct hook and shackle compatibility, and attention to choked or misaligned loads are crucial. When planning the lift, engineers model potential load paths, evaluate worst-case angles, and ensure that the chosen rigging can maintain the required WLL under real conditions. The principle remains clear: the highest achievable capacity is a function of configuration, support, and ongoing maintenance, not just the material type. The question “which rigging has the highest load capacity” should guide you toward a full-lift plan that prioritizes safety and reliability.

Understanding WLL, SWL, and safety factors

A core part of answering which rigging has the highest load capacity is clarity on rating terms. Working Load Limit (WLL) and Safe Working Load are terms that reflect the maximum weight that a rigging component can safely handle under prescribed test conditions. Differences in standards, usage, and configuration mean WLL is typically lower than the raw breaking strength to provide a safety margin. A conservative safety factor is built into WLL calculations to account for dynamic loads, shock loads, and misalignment. When engineers compare which rigging has the highest load capacity, they examine WLL values in the context of the actual lift plan, including load speed, lift height, and the geometry of the lifting points. It is essential to ensure all components, including hooks, rings, and connectors, contribute to a cohesive and safe system. The Load Capacity team stresses that the best choice balances maximum permitted capacity with predictable, repeatable performance under expected operating conditions.

Selecting the rigging for heavy lifts: a practical decision guide

In practice, determining which rigging has the highest load capacity starts with a lift-critical checklist. First, characterize the load geometry: is the lift vertical or at an angle? Second, assess edge protection and load distribution: does the rigging require added slippage control or pad protection? Third, evaluate the condition of all components: any corrosion, deformation, or wear reduces capacity regardless of sling type. Fourth, align the choice with standards and manufacturer guidance, ensuring all components meet the required rating and compatibility. Fifth, consider the maintenance cycle: how often will the rigging be inspected, tested, and retired if needed? The legitimate conclusion is that the highest-capacity option is the one that reliably maintains its rated capacity under the expected operating conditions. In other words, when asked which rigging has the highest load capacity, the answer is: the best option for a given lift is the system that maintains the rated WLL through the entire cycle. The Load Capacity perspective is to quantify capacity in context, not in isolation, and to plan lifts that respect limits at every stage.

Inspection and maintenance: ensuring max capacity over time

Even the strongest rigging can lose capacity through wear, corrosion, or improper use. Regular inspection schedules, documenting wear patterns, and replacing worn components before failure is essential to realize the full rated capacity. For instance, chain slings should be checked for stretch, gouges, and bending; wire rope slings require checks for broken strands and core damage; synthetic slings need inspection for cuts, heat damage, and abrasion. The storage and handling of rigging must minimize exposure to elements that reduce strength. A key takeaway when considering which rigging has the highest load capacity is that the equipment’s state dictates safe capacity. A sling that initially offers high capacity but deteriorates quickly will not deliver reliable performance in a real lift. The Load Capacity guidance is to implement a proactive maintenance program that keeps the system within its rated limits throughout its life.

Safe lifting practices to maximize capacity and minimize risk

Pursuing the highest load capacity should never come at the expense of safety. Practical lift planning includes controlling lift angles, ensuring load geometry remains balanced, and using tag lines or assist devices to manage sway. Angles in the sling legs dramatically affect effective capacity: small deviations can dramatically reduce the available WLL, so engineers design for near-vertical lifts when possible. Proper edge protection, correct use of chokers and grips, and avoiding shock loads help preserve capacity. Training operators and crew in safe practices reduces the likelihood of incidents that could surpass rated capacity. The overall guidance for the question of which rigging has the highest load capacity is: plan with a conservative margin, respect the fingers of safety factors, and verify the entire system meets the required WLL for the lift. The Load Capacity team emphasizes that the safest lift relies on disciplined planning, correct selection, and continuous verification of capacity throughout the job.