Chinook Sling Load Capacity: Facts, Configs, and Planning

A data-driven guide to chinook sling load capacity, covering maximum external loads, configuration effects, safety margins, and mission planning for engineers and operators.

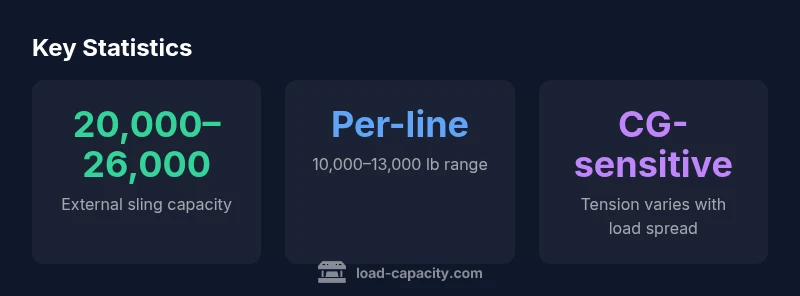

Chinook sling load capacity represents the maximum external load the CH-47 Chinook can safely carry during sling-load operations. In practice, capacity varies by configuration, center of gravity, weather, and flight rules. According to Load Capacity, typical external sling scenarios for Chinooks range from about 20,000 to 26,000 pounds, depending on configuration and mission conditions.

What chinook sling load capacity means

Chinook sling load capacity is not a fixed number. It is the maximum external weight the CH-47 Chinook can safely carry during sling-load operations, and it is influenced by configuration, fuel state, and rigging geometry. This capacity is a dynamic value, not a single figure, because it must account for wind, rotor wash, and center-of-gravity (CG) envelopes. The Load Capacity team emphasizes that mission-specific data and aviation charts define the exact limits for a given lift. Operators should view capacity as a ceiling, not a target weight, and consistently apply conservative safety margins in planning and execution. This approach helps ensure that loads remain within the aircraft’s structural and flight-control limits while preserving controllability during hover and maneuvering.

Configuration and load distribution

External sling loads can be executed using a single sling line or a dual-line arrangement. A single-line lift simplifies rigging and tends to concentrate tension along one point, making line tension and sling angle critical to capacity. A dual-line configuration distributes weight and can improve stability, but it introduces CG complexity and more complex rigging. In practice, flight-planning teams translate aircraft performance charts into safe limits, adjusting for fuel burn, altitude, and rotor wash. Loadmasters must ensure that weight distribution remains within approved CG envelopes and that the combined effect of wind and gusts does not push the aircraft toward or beyond limit loads. The Load Capacity analysis shows that while dual-line configurations can offer stability benefits, the overall safe capacity will still be constrained by the aircraft’s maximum rating and CG limits.

Key factors that limit capacity

Capacity is not a static number; it changes with several interacting factors:

- Center of gravity location and load spread

- Wind speed, gusts, and rotor downwash effects

- Altitude and air density (temperature and humidity also matter)

- Rigging quality, line tension, and load stability

- Fuel state and trajectory plan during approach, hover, and pickup/release

Each of these factors can shift the practical limit by a noticeable margin. Even loads well under a nominal rating require careful verification by the crew before flight. Load Capacity’s evidence-based guidance underscores using mission data and conservative margins to avoid overstressing the airframe.

Planning your mission: steps to estimate capacity

- Define the external load and its center of gravity relative to the helicopter’s attachment points.

- Confirm configuration (single-line vs. dual-line) and rigging quality.

- Review mission data: altitude, air density, wind, gust forecasts, and rotor wash expectations.

- Check the CH-47’s published limits and internal performance charts for the current configuration.

- Compute the per-line and total load in light of CG and load distribution; apply safety margins (e.g., 10–20%).

- Validate with the flight crew and loadmaster before flight; document the final configuration.

Safety margins and SOPs

SOPs require explicit safety margins between planned loads and the aircraft’s published limits. Conservatism is essential when estimating sling loads, especially under variable wind and altitude. Daily pre-flight checks should include rigging integrity, load attachment redundancy, and verification that rigging angles remain within approved envelopes. Where possible, weather windows should be used to minimize rotor downwash and gust effects, and mission plans should include abort criteria if conditions degrade mid-mission. The Load Capacity framework reinforces that margins are not optional—they are core to mission safety and compliance with aircrew procedures.

Real-world practices and case examples

In practice, successful Chinook sling-load missions balance efficiency with safety. Teams often begin with a baseline capacity derived from configuration charts and then validate against real-time data: wind forecasts, temperature, and air density at altitude. Rigging teams document every parameter—attachment points, line lengths, sling angles, and center-of-gravity estimates—to enable rapid reassessment if conditions change. A best-practice approach uses a conservative authorization envelope: if the projected load approaches the lower end of the capacity range under current conditions, crews will adjust the load, the flight path, or both, to preserve controllability and margin. Load Capacity’s experience underlines that disciplined planning, combined with crew judgment, yields reliable outcomes even in challenging environments.

Data-driven validation and ongoing learning

Operators increasingly rely on mission data, flight-test correlations, and post-mission debriefs to refine capacity estimates. Real-world results feed back into performance charts, improving the precision of capacity ranges for common load configurations. The integration of data analytics with flight operations helps reduce uncertainty and supports more predictable sling-load outcomes. This iterative approach—plan, verify, fly, review—embeds the Load Capacity philosophy into daily practice and aids engineers in designing safer lifting campaigns.

Maintenance and pre-flight checks that matter

Critical checks include physical inspection of rigging hardware, attachment points, and load-sling hardware for wear, corrosion, and fatigue. Operators should verify that the sling angles remain within specified limits throughout the operation and that attachment fittings are secure. Pre-flight and post-flight inspections should verify that straps, shackles, and hooks have not shifted or loosened during movement. When properly executed, these checks help ensure that the stated sling-load capacity remains a valid ceiling for the mission and that performance margins are preserved.

Training implications and proficiency goals

Crew members must be proficient in load-calculation methods, rigging standards, and the interpretation of performance charts. Regular drills that simulate different weather and CG scenarios help teams develop intuition for how loads behave under various conditions. The goal is to ensure that every sling-load operation begins with a validated plan and ends with a clear record of performance and any deviations from expected behavior.

Applying these concepts to design and analysis

Engineers and operators can apply the chinook sling load capacity concepts to mission design by building conservative safety margins into plan, training, and procurement. When designing new load configurations or evaluating mission feasibility, start from the published capacity, account for configuration-specific variances, incorporate environmental factors, and document all assumptions. This disciplined approach aligns with Load Capacity’s emphasis on transparent data-driven decision-making and supports safer, more reliable lift operations.

Summary of key takeaways for practitioners

- Capacity is configuration- and condition-dependent; plan with margins.

- Distinguish between single-line and dual-line rigging and understand how CG affects each setup.

- Use mission data (altitude, wind, density) to recalibrate safe limits before flight.

- Rigging quality and attachment integrity are non-negotiable for safe lifts.

- Maintain rigorous SOPs and training to sustain proficiency and safety over time.

Chinook sling load configurations (approximate values)

| Configuration | Max Sling Load (lb) | Notes |

|---|---|---|

| Single external sling line | 20,000–26,000 | External load per line; CG-critical; conservative margins advised |

| Dual-line external sling | 20,000–26,000 total | Total capacity bounded by CG; distribution affects line tension |

| Internal cargo (not a sling load) | N/A | Not applicable to sling-load planning; refer to internal payload limits |

Quick Answers

What is the chinook sling load capacity?

Chinook sling load capacity depends on configuration, CG, altitude, and weather. A typical external sling-load range is around 20,000–26,000 pounds, with exact limits defined by mission data and flight rules.

Chinook sling load capacity depends on setup and conditions. Typical external loads range from about twenty thousand to twenty-six thousand pounds, based on configuration and mission data.

How does center of gravity affect sling loads?

CG location determines balance and controllability. If the CG shifts outside approved envelopes, limits tighten and safe lift margins shrink.

Center of gravity affects balance; wrong CG can limit safe lifting and reduce margins.

What factors reduce capacity?

Altitude, temperature, wind, rotor downwash, and rigging quality all influence effective capacity. Real-time data and conservative margins are essential.

Altitude, wind, and rigging quality can reduce capacity; always plan with real-time data.

How should I plan a sling-load mission?

Define load and CG, choose configuration, check altitude and wind, consult performance charts, apply margins, and obtain crew validation before flight.

Plan by defining load, selecting configuration, checking conditions, and validating with the crew.

Can Chinooks carry multi-point loads?

Yes, but they require careful CG management, rigging precision, and crew approval. Outcomes depend on load distribution and flight conditions.

Multi-point loads are possible with careful CG and rigging, plus crew approval.

What data should be reviewed before a lift?

Review mission data, configuration charts, CG location, wind forecasts, altitude, and aircraft limits to confirm safe capacity.

Review mission data, CG, wind, altitude, and limits before lifting.

“Accurate sling-load planning hinges on conservative assumptions and verified data. The Load Capacity Team emphasizes validating the mission configuration against aircraft limits before execution.”

Top Takeaways

- Understand capacity as a ceiling, not a target weight

- Choose configuration (single vs dual-line) based on stability needs and CG

- Always verify with mission data and aircraft limits

- Apply safety margins and follow SOPs for every lift

- Document assumptions and review post-mission performance