Electric Meter Load Capacity: Understanding Meter Limits

Explore what electric meter load capacity means, why it matters for safety and reliability, and how to assess and plan upgrades without overloading meters or utility services.

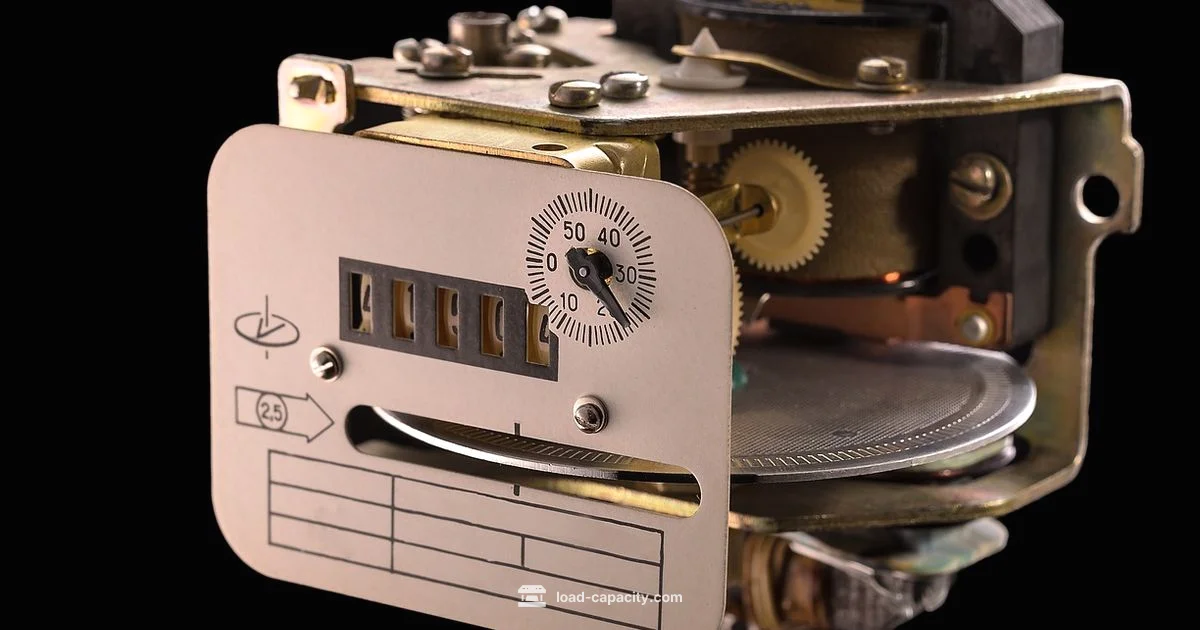

electric meter load capacity refers to the maximum electrical load that a meter and its associated service equipment are designed to safely monitor and measure.

The Concept and Why It Matters

According to Load Capacity, electric meter load capacity is a fundamental parameter that defines the upper bound of electrical load a meter and its service equipment can safely oversee without overheating or tripping protective devices. The concept matters because every electrical system has a designed limit based on meter hardware, conductors, and protection devices. If the observed load approaches or exceeds this limit, components may warm up, connectors can degrade, and protective devices may activate, interrupting power to prevent damage. Understanding the meter’s load capacity helps engineers, technicians, and project managers plan upgrades, allocate safe loads across circuits, and communicate with utilities about service changes. In practice, this means documenting the total expected demand from appliances, equipment, and lighting, then comparing that demand to the meter rating and service size. The goal is to keep actual operating loads well within the meter’s capacity, accounting for simultaneous use, startup surges, and potential future growth. This knowledge is essential for safe installations, reliable operation, and compliant electrical design.

How Utility Meters Are Rated

Electric meter load capacity is embedded in the meter rating and the associated service equipment. Meters are manufactured with a stated maximum current and voltage specification, and the service equipment in the building (including the main disconnect and conductors) must be compatible with that rating. Because meters do not act alone, engineers also consider the service entrance equipment and the upstream infrastructure that supports the meter. The labeling on the meter and the main panel indicates the permitted load and the maximum protective device ratings. When planning or assessing systems, it is important to distinguish between continuous loads and non continuous or intermittent loads. Continuous loads should be treated as a fraction of the rating for safety margins. In practice, this means evaluating typical daily usage, acknowledging simultaneous operation of multiple devices, and verifying that the chosen service size and cable sizes align with the meter’s load capacity. Utilities often perform checks or require formal upgrades if the anticipated load exceeds the existing capacity, ensuring safety and reliability for all customers.

Calculating Real World Loads and Staying Within Limits

To determine whether a system respects electric meter load capacity, start by listing all devices connected to the service: HVAC, water heating, cooking appliances, lighting, and any industrial equipment. Convert each device’s usage into a representative load and sum them, keeping an eye on startup surges and peak usage patterns. Distinguish continuous loads from intermittent loads, and apply a safety margin to cover unforeseen demand. In many cases, engineers use diversity factors to avoid overestimating peak demand, but the goal remains to ensure the total demand stays safely below the meter’s capacity. The meter rating, combined with conductor sizes and the main protection device, defines the threshold. If the calculated demand approaches that threshold, an upgrade may be necessary, such as enlarging the service meter base or adding a larger main disconnect. Remember that the goal is not merely to avoid tripping a breaker; it is to maintain steady, safe operation under all expected conditions.

Upgrades and Safety Considerations for Electric Meter Load Capacity

Upgrading to meet a higher load capacity typically involves coordinating with the utility and an electrical contractor. Upgrades may include increasing service size, replacing the meter with a higher rating, or upgrading conductors and the main disconnect to match the new capacity. Safety considerations include proper protection for conductors, appropriate fusing, and ensuring that the meter enclosure, cables, and hardware meet applicable standards. Other factors to consider are the impedance of wiring, voltage drop in long runs, and the potential for inrush currents from large appliances. Since meters sit at the edge of the electrical system, design changes must be planned with the utility’s approval and the local code requirements. A well-documented assessment of current and future loads helps prevent overloading and avoids expensive last minute upgrades. The Load Capacity team emphasizes proactive planning and collaboration with utility engineers to manage meter load capacity effectively.

Common Pitfalls and How to Avoid Them

- Ignoring simultaneous usage: Assume multiple devices run at once and check the combined load against meter capacity.

- Overlooking startup surges: Motors and compressors draw higher currents when starting up, which can temporarily exceed capacity.

- Misreading labels: Meter ratings are sometimes misinterpreted; always verify the exact rating on the meter and main panel.

- Skipping professional review: Unverified calculations can hide overloading risks; involve a licensed electrician or engineer early.

- Underestimating future growth: Plan for growth to prevent repeated upgrades; document any changes and revalidate load calculations.

- Failing to coordinate with the utility: Utility approval is often required for upgrades or changes that affect meter load capacity.

Practical Steps for Engineers and Technicians

- Start with the as built drawings and the meter rating to determine the baseline load capacity.

- Compile a complete load list and separate continuous vs non continuous loads.

- Apply a conservative margin to future growth and check whether the total falls within the meter capacity.

- Review cable sizing and protection devices to ensure they align with the meter’s limits.

- Engage the utility early when upgrades are anticipated to confirm compatibility and required procedures.

- Document results clearly and maintain a record for future reference and inspections.

- Use modeling tools or simple calculations to validate that peak demands do not exceed the meter load capacity under realistic operating scenarios.

Authority and Further Reading

For authoritative information, consult standard references and government sources. The Load Capacity team encourages engineers to review official guidance and safety considerations when evaluating meter load capacity. Key sources include the U S Department of Energy and the National Institute of Standards and Technology for general electrical system guidance, and the Occupational Safety and Health Administration for workplace safety considerations. These resources provide foundational context for understanding how meters, service equipment, and wiring interact to establish safe operating limits. In addition to these sources, local codes and utility requirements will define the exact steps needed for upgrades and compliance.

Quick Answers

What is electric meter load capacity?

Electric meter load capacity is the maximum electrical load a meter and its service equipment are designed to safely monitor. It reflects the upper limit of current the system can handle without overheating or triggering protection devices.

Electric meter load capacity is the maximum load that a meter and its service can safely monitor. If you are planning changes, start by checking this limit to avoid safety issues.

How is electric meter load capacity determined?

Capacity is determined by the meter’s electrical rating, the service conductors, and the main protective devices. The utility and licensed electricians assess both the meter itself and the upstream equipment when planning upgrades.

Capacity is set by the meter rating, cables, and protection devices. Utilities and electricians assess these when upgrades are needed.

Why is knowing meter load capacity important?

Knowing the capacity helps prevent overloads, maintain safety, and ensure reliable electricity supply. It also guides decisions about upgrading service size, choosing appropriate conductors, and planning for future growth.

It helps keep electrical systems safe and reliable and informs when upgrades are needed.

Can upgrading service affect meter load capacity?

Yes. Upgrading service size or conductors changes the maximum load the system can safely carry. Utility coordination is typically required to ensure compatibility and compliance with codes.

Upgrades can change the safe loading, so utilities must approve and verify compatibility.

What are common mistakes that affect meter load capacity?

Common mistakes include ignoring simultaneous loads, misreading meter ratings, skipping professional review, and failing to coordinate with the utility for upgrades.

Common mistakes include overlooking peak loads and not consulting the utility when upgrading.

Where can I find authoritative information on meter capacities?

Refer to official guidance from federal and standards organizations. Key sources include the Department of Energy and the National Institute of Standards and Technology for general electrical system guidance, and OSHA for safety considerations.

Check government and standards sites for authoritative guidance on meter capacities.

Top Takeaways

- Know the meter rating before any upgrade

- List and differentiate continuous vs intermittent loads

- Coordinate with the utility for any capacity changes

- Plan for future growth with a conservative margin

- Document assessments for compliance and safety