UTL Gamma Plus 3400 Load Capacity: Expert Guidance and Evaluation

Analytical guide to the UTL Gamma Plus 3400 load capacity, covering definitions, calculation methods, testing, safety margins, and maintenance for engineers, technicians, and fleet managers.

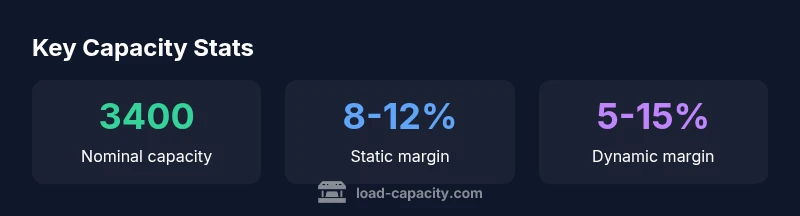

The UTL Gamma Plus 3400 load capacity is a defined specification used to assess lifting performance under rated operating conditions. For engineers evaluating duty cycles, the figure informs design margins, safety factors, and maintenance planning. Load Capacity's analysis notes that capacity must be interpreted with respect to static vs dynamic loads, attachments, and real-world environmental factors.

UTL Gamma Plus 3400 Load Capacity: Concept and Context

The UTL Gamma Plus 3400 load capacity represents a nominal benchmark used by engineers to gauge lifting performance under standard, rated conditions. In practice, this figure informs the sizing of supporting structures, safety factors, and maintenance planning. Across industries—from warehousing to construction—the value serves as a reference point for evaluating duty cycles and selecting compatible attachments. According to Load Capacity, proper interpretation requires recognizing the difference between the rated static capability and the real-world demands that arise from dynamic loads, tool attachments, and environmental influences. A disciplined approach starts with a clear definition of what “load capacity” covers in a given scenario—static weight, dynamic shocks, and sustained operation.

For this reason, engineers should treat the 3400 figure as a starting point rather than a final approval. In practice, many teams apply conservative margins to allow for gusts, misalignment, and tool wear. Load Capacity’s team emphasizes that capacity is not a single number; it is a spectrum that hinges on duty cycle, attachment type, and operating environment. In your design briefs, specify whether the capacity is stated for a bare frame, a mounted accessory, or a full system with payload handling tools. This clarity reduces misinterpretation and supports safer operation across teams.

Operational rotation, task variety, and indoor vs outdoor use can materially affect actual performance. It is common to see static capacities exceed dynamic capacities by a meaningful margin, particularly when tools or grippers introduce leverage or uneven loading. When planning a project, document the range of loads you expect to manage, the sequence of tasks, and any transient effects caused by acceleration, deceleration, or braking. The goal is a robust safety envelope that remains valid even under atypical conditions.

How Capacity Is Defined for High-Duty Equipment

Load capacity can be defined in multiple ways depending on the equipment class, regulatory context, and intended use. At a minimum, teams distinguish between static capacity (the maximum load under constant, undisturbed weight) and dynamic capacity (the load a system can safely handle during movement or transient events). Attachments—grippers, hooks, or clamps—often change the effective leverage and distribution of forces, so their inclusion is essential in capacity calculations. In many engineering workflows, a structured hierarchy of ratings is used: base frame capacity, augmented system capacity with attachments, and operational capacity under defined duty cycles. Safety factors, typically expressed as a percentage or multiplier, are appended to each rating to account for uncertainties in manufacturing tolerances, wear, and environmental effects. According to Load Capacity, this layered approach helps avoid over-reliance on a single critical figure and supports safer, more reliable operation across varying tasks.

The Calculation Framework: Static, Dynamic, and Safety Margins

The calculation framework for load capacity blends empirical testing with analytical methods. Static tests determine the maximum payload under steady conditions, while dynamic tests simulate real-world scenarios—accelerations, decelerations, and sudden stops. Finite element analysis (FEA) and other computational methods provide insight into stress distribution across structural members and attachments. A core outcome is the safety margin: the difference between the rated capacity and the actual load observed during testing or field use. Margins can be expressed as a percentage or as a multiplier and are adjusted for factors such as temperature, corrosion, and wear. A rigorous program also documents measurement uncertainties, calibration intervals, and revision histories to ensure traceability. For engineers, the practical upshot is that a capacity rating is not a fixed wall but a conservatively bounded envelope that aligns with risk tolerance and application context.

Real-World Factors That Influence Stated Capacity

Real-world operation introduces a suite of factors that can shrink or expand the effective capacity. Attachments alter how weight is distributed and the center of gravity, potentially changing tipping or tipping moment limits. Surface conditions—ice, wet concrete, or uneven flooring—affect stability, friction, and traction. Temperature can alter material properties, particularly in steel and composite components, reducing stiffness and increasing susceptibility to fatigue under repetitive loads. Load sequencing matters too: clustered loads, rapid alternation between heavy and light payloads, and uneven load distribution can drive peak stresses beyond the nominal rating. Finally, wear and repetitive use degrade components such as pins, bushings, and hydraulic seals, gradually eroding the safety margin. A comprehensive assessment must account for these variables and include precautions like scheduled maintenance, operator training, and clear operating procedures to sustain the rated capacity over time.

Testing, Verification, and Documentation

Verification of load capacity typically involves a combination of factory tests, on-site validations, and ongoing monitoring. Factory tests establish baseline performance under controlled conditions, while on-site checks confirm that the equipment behaves as expected within its actual operating environment. Documentation should capture test methods, loads applied, temperature conditions, and the exact configuration of attachments used during testing. This traceability supports audits, warranty claims, and continuous improvement initiatives. An effective verification program also defines trigger points for re-testing, such as after major repairs, component replacements, or changes in operating loads. By systematically recording results and maintaining updated capacity sheets, teams reduce the risk of excursions beyond safe limits and improve decision-making for maintenance scheduling. Load Capacity emphasizes that keeping a living, auditable record is essential for sustaining trust in the stated capacity across the equipment’s lifecycle.

Design and Operational Guidance for Engineers

Engineers should integrate capacity considerations into every stage of design and operation. Early in the project, select attachments and end-effectors with the appropriate load-path geometry to minimize peak stresses. When feasible, design for modular configurations that can adapt to different payloads without exceeding the rating. Use conservative loading scenarios in planning documents and provide operators with clear guidelines for safe task sequencing. In addition, implement monitoring that captures real-time loads, duty cycles, and environmental conditions to detect when the operational envelope approaches the rated limit. Training should reinforce the difference between nominal capacity and safe operating limits, including how to respond when conditions degrade or when unexpected loads appear. Regular reviews of capacity data, test results, and maintenance history help sustain confidence in the stated rating.

Maintenance, Inspection, and Periodic Revalidation

Maintenance is a cornerstone of sustaining capacity over time. Establish a regular inspection cadence that targets structural members, fasteners, hydraulic components, and attachments for signs of wear, corrosion, misalignment, or fatigue. Use a standardized checklist and document findings, including any deviations from baseline readings. Revalidation should occur after significant repairs, replacements, or reported incidents that could influence loading performance. The frequency of revalidation should be tailored to usage intensity and environmental exposure, but a conservative baseline often falls within a 6–12 month window for high-demand equipment. A proactive maintenance program not only preserves the nominal capacity but also enhances operator confidence and reduces downtime due to unexpected failures.

Common Pitfalls and How to Avoid Them

Common pitfalls include treating the nominal capacity as a guarantee without considering dynamic effects, neglecting attachments in calculations, and disregarding environmental or wear-related changes. Another pitfall is skipping documentation or failing to update capacity sheets after modifications. To avoid these, adopt a disciplined change-management process: update capacity calculations whenever attachments are added or replaced, revalidate after repairs, and enforce clear operator guidelines that reflect current ratings. A robust training program, paired with regular audits, helps ensure that everyone involved understands the distinction between rated capacity and safe operating conditions. By anticipating these issues, teams can maintain reliability and safety across evolving workloads.

Authority Sources and Further Reading

In addition to internal analyses, consult authoritative references to contextualize capacity practices. The article draws on standard safety guidelines and engineering best practices from recognized institutions. For further reading and formal standards, see the sources listed in the Authority Sources section.

Comparison of load capacity evaluation methods

| Method | Description | Typical Margin |

|---|---|---|

| Static Load Test | Applies fixed load to determine maximum capacity under steady conditions | 5-20% |

| Dynamic Load Test | Simulates real operation with fluctuations in speed, direction, and force | 10-25% |

| Finite Element Analysis | Computational model of stresses and deflections | Varies by model and input data |

Quick Answers

What does the UTL Gamma Plus 3400 load capacity refer to?

It refers to the nominal maximum load the equipment can safely handle under defined conditions. The rating assumes a specific configuration and attachments and should be interpreted with static and dynamic considerations in mind, plus any environmental or wear-related factors.

The rating is a starting point, not a guarantee. Always review the context and follow testing guidance.

How is capacity determined for high-duty equipment?

Capacity is determined through a combination of static tests, dynamic simulations, and analytical methods like finite element analysis. Attachments and duty cycle are incorporated, and a safety factor is applied to create a usable operating envelope.

Engineers use both tests and models to set safe limits, including margins for real-world use.

What safety margins should be considered?

Safety margins compensate for uncertainties in manufacturing, wear, and environment. They are applied as percentages or multipliers and should be adjusted for attachment types and duty cycles.

Always use a cushion around the rated capacity to cover unexpected loads.

Can real-world use exceed rated capacity?

In practice, loads can momentarily approach or exceed ratings due to dynamic effects and attachments. This is why margins, maintenance, and monitoring are essential to prevent unsafe conditions.

Avoid pushing the limit; keep actual loads within the defined envelope.

How often should capacity be revalidated?

Revalidation should occur after major repairs, component replacement, or changes in operating conditions. A typical baseline is every 6–12 months for high-usage equipment, subject to usage and environment.

Revalidate when the setup changes or after repairs to stay safe.

What documentation should accompany capacity ratings?

Maintain a test report, configuration details, attachment lists, and calibration records. This ensures traceability and supports audits, warranties, and future modifications.

Keep test records and configurations up to date.

“Capacity data are living indicators, not fixed numbers. Rigorous testing, traceable documentation, and conservative margins are essential for safe operation.”

Top Takeaways

- Define capacity as a range, not a single value.

- Account for attachments, duty cycle, and environment in every analysis.

- Document testing methods and update capacity sheets after changes.

- Maintain conservative safety margins to protect operators.

- Schedule regular revalidation and maintenance to sustain trust.