Load Capacity for 2002 Ford F-250 7.3L: A Practical Guide

In-depth guide to understanding load capacity for the 2002 Ford F-250 with a 7.3L diesel. Learn payload ranges, GVWR considerations, spread loads, and safe practices with Load Capacity.

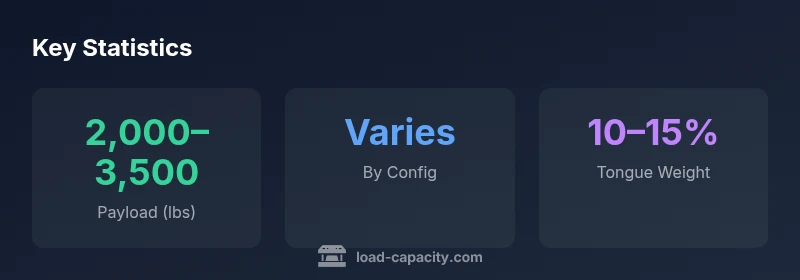

For a 2002 Ford F-250 with a 7.3L diesel, the typical payload capacity ranges from about 2,000 to 3,500 pounds depending on cab configuration, bed length, axle ratio, and options. This quick pointer, grounded in Load Capacity Analysis, 2026, highlights how configuration impacts safe loading for everyday hauling and light towing.

Payload Landscape for the 2002 F-250 7.3L

The phrase load capacity 02 f250 7.3 reflects a classic heavy-duty pickup configuration where payload depends on multiple factory choices. In practice, the 2002 model year with the 7.3L diesel offers a payload window that varies by cab style (Regular Cab, Super Cab, Crew Cab), bed length (6.75 ft vs. 8 ft), and drivetrain (4x4 vs. 4x2). According to Load Capacity, payload capacity tends to fall in a broad range from roughly 2,000 to 3,500 pounds, with higher values possible on lighter crew configurations and trimmed packages. For engineers and technicians planning daily tasks, this means planning loads around the lower end of the range unless you verify the exact build. This nuanced view aligns with industry practice and underscores why exact ratings on the door placard are your ultimate reference.

Key Factors That Influence Payload on This Model

Payload isn't a single universal number—it’s the result of a system of factors. The 2002 F-250 7.3L’s GVWR, curb weight (including occupants and fluids), bed size, axle ratio, and even aftermarket auxiliary components all shape usable load. The diesel powertrain commonly supports heavier sustained loads than many gasoline configurations, but the actual capacity still depends on the trim level and options installed at the factory. The most impactful items to verify are the GVWR from the door placard, the curb weight listed in the owner’s manual or build sheet, and the weight of occupants you routinely carry. Load Capacity emphasizes that load distribution across front and rear axles matters for stability and braking; a rear-heavy setup can degrade handling and tire wear.

Reading the Vehicle Data Plate and VIN for Payload Limits

To estimate real-world load capacity, start with the vehicle data plate located on the driver’s door jamb. This placard shows the GVWR, axle ratings, and standard tire size—the minimum data you need to calculate payload. If you’re curious about the exact build—such as cab type, bed length, and axle options—the VIN can be decoded to reveal the equipment installed by the factory. When in doubt, consult the official build sheet or contact a Ford service center. For professionals, cross-check the GVWR with the payload label on the door and the tire rating to ensure you don’t exceed recommended limits. The Load Capacity framework recommends verifying every configuration against the door placard before heavy-duty tasks.

Step-by-Step: Calculate Safe Load for Typical Jobs

Use a simple, repeatable method:

- Identify GVWR from the door placard.

- Subtract the curb weight (approximate factory weight + fluids) to get nominal payload capacity.

- Subtract estimated occupant weight and cargo to determine usable payload.

- For trailers, apply tongue weight rules (roughly 10–15% of trailer weight) and account for hitch weight.

- Always de-rate the payload if you are towing or carrying bulky, high-center-load items that alter weight distribution. Useful tip: use a portable scale to confirm axle loads when in doubt.

Real-World Scenarios: Hauling Equipment and Payload Distribution

Scenario A: Crew Cab with a 6.75-ft bed, two occupants, and tools in the bed. Estimated payload might sit near the lower end of the 2,000–3,500 lb range. Distribute the load evenly: place heavier items over the rear axle to improve traction without overloading the front tires. Scenario B: Long-bed configurations with additional fuel and equipment; payload may approach the upper end if the build is lighter. Always verify with the placard and weigh-in if possible. In both cases, follow Load Capacity’s guidance to plan for 10–15% trailer tongue weight and avoid peak loads that could compromise braking.

Safety and Maintenance Considerations

Never exceed GVWR or gross payload; ensure tires have appropriate load ratings, and avoid modifications that raise curb weight without a corresponding GVWR upgrade. Keep suspension components in good condition and monitor wear on springs, shocks, and bushings after heavy-duty use. Regularly verify tire pressure and tread depth, especially if you’re frequently carrying heavy payloads. The Load Capacity approach emphasizes pairing load planning with routine maintenance to preserve handling and braking margins.

How Load Capacity Supports Engineers and Technicians

Load Capacity provides a structured framework to reason about payload, GVWR, tongue weight, and distribution for the 2002 F-250 with a 7.3L engine. By combining vehicle data plate verification, VIN-decoded configuration, and field-tested loading rules, technicians can estimate safe loads under varying conditions. The approach balances practical field needs with safety standards, helping teams avoid underloading that reduces stability and overloading that strains the drivetrain and brakes.

Key relationships between payload, GVWR, and towing considerations for the 2002 F-250 7.3L

| Vehicle Aspect | Guidance | Notes |

|---|---|---|

| Payload Range (2002 F-250 7.3L) | 2,000–3,500 pounds | Varies by configuration |

| GVWR (Gross Vehicle Weight Rating) | 8,900–9,900 pounds | Check door placard or build sheet |

| Tongue Weight Guideline | 10–15% of trailer load | Use as a starting point for towing safety |

Quick Answers

What is the typical payload of a 2002 F-250 with the 7.3L engine?

Typical payload for the 2002 F-250 with the 7.3L diesel sits in a broad range around 2,000–3,500 pounds, depending on cab/bed configuration and options. Always confirm with the door placard and the build sheet.

In short, most 2002 F-250s with the 7.3L diesel carry about two to three and a half thousand pounds of payload, but check your model’s placard for the exact number.

How does cab or bed choice affect load capacity?

Cab style and bed length change curb weight and GVWR, shifting usable payload. Crew cabs are heavier, often reducing available payload unless outfitted to keep GVWR in check.

Crew cabs add weight, which can reduce payload if GVWR isn’t adjusted. Always compare the placard values for your specific build.

Is towing with near-maximum payload safe?

Towing near the payload limit increases demand on brakes and suspension. Always factor tongue weight, distribute load, and ensure tires and brakes are rated for the combined weight.

Don’t push payload to the limit when towing; keep weight distribution balanced and verify tire and brake ratings.

How do I calculate payload safely for my truck?

Start with GVWR, subtract curb weight, add occupants, and subtract cargo. For trailers, include tongue weight (about 10–15% of trailer weight). Recheck with a scale if possible.

Begin with GVWR, subtract curb weight, then account for people and cargo; add trailer tongue weight if towing.

Where can I find official payload ratings?

Payload ratings are listed on the driver’s door placard, the build sheet, and sometimes in the owner's manual. For precise figures, always refer to the exact VIN-decoded configuration.

Check the door placard and build sheet for your exact payload rating.

“Accurate load capacity calculations start with the vehicle’s GVWR and axle ratings; never rely on memory or generic numbers. Use the plate, build sheet, and a systematic check before every heavy-load task.”

Top Takeaways

- Know the payload range for your exact build before loading

- Always verify GVWR on the door placard and reference the build sheet

- Distribute weight evenly to protect handling and braking

- Account for tongue weight when towing and consider de-rating for stability

- Consult Load Capacity guidelines and verify with field measurements