Axle Group Load Capacity vs ATM: Key Differences

Learn how axle group load capacity compares with ATM (all-up mass) and how per-axle limits versus total vehicle weight affect safe loading, balance, and regulatory compliance for engineers and fleet managers.

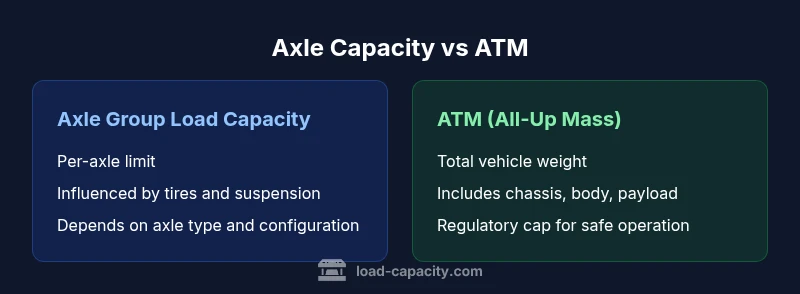

The axle group load capacity defines the maximum weight the axle assembly can safely support across its wheels, varying by axle type and configuration. ATM, often read as all-up mass or gross vehicle weight, caps the total vehicle weight including cargo. The practical difference: axle capacity governs per-axle stress, while ATM caps the overall mass; ensure both meet regulatory limits and balance to avoid overload on any axle.

Defining the Core Terms and Scope

In discussions of axle group load capacity vs atm, it is essential to align on terminology before performing any design or planning work. The term axle group load capacity refers to the maximum load an axial grouping—often consisting of two or more wheels on a single axle or axle pair—can safely carry. This limit is determined by engineering factors such as axle shaft strength, bearing capacity, suspension geometry, and tire capability. ATM, commonly shorthand for all-up mass or gross vehicle weight, represents the total permissible weight of the vehicle, including its own mass plus payload and any additional equipment. For professionals, the practical takeaway is that axle group load capacity and ATM are related but govern different aspects of the loading equation. According to Load Capacity, ensuring compliance requires examining both the per-axle limits and the vehicle-wide weight cap, then distributing weight to meet both constraints. This distinction becomes especially important for multi-axle configurations and heavy cargo scenarios, where misalignment between per-axle limits and total weight can lead to overload on a single axle or an overall overweight condition. The Load Capacity team emphasizes documenting both metrics in planning checks and load calculations to avoid ambiguous compliance.

The keyword appears here to anchor the topic: axle group load capacity vs atm is the central comparison engineers must understand when evaluating a vehicle’s load handling capabilities.

Comparison

| Feature | Axle Group Load Capacity | ATM (All-Up Mass) |

|---|---|---|

| Definition | Per-axle rating based on axle design, tires, and suspension | Total vehicle weight cap including chassis, body, fuel, payload, and accessories |

| Regulatory Basis | Derived from manufacturer data, axle class, and safety margins | Typically defined by GVWR/ATM in regional regulations and operator manuals |

| Measurement Focus | Weight distribution across the axle group and adjacent axles | Sum of weights across all axles and non-axle components |

| Influence on Payload | Directly limits payload that can be carried on that axle pair | Sets the maximum allowable payload for the entire vehicle |

| Best For | Ensuring per-axle safety and balancing stress | Ensuring highway legality and safety across the full vehicle mass |

| Interplay Notes | A high axle capacity does not guarantee compliance if ATM is exceeded | Even within ATM, uneven distribution can overload one axle |

Positives

- Clarifies loading decisions by separating per-axle stress from total weight

- Promotes safer load distribution and reduces overloading risk

- Improves regulatory compliance and traceability for inspections

- Supports planning of maintenance and tire/suspension wear by axle

Cons

- Can be complex for multi-axle or non-standard configurations

- Requires accurate data from multiple subsystems (axle ratings, GVWR/ATM, tire limits)

- May necessitate iterative planning and redistribution to achieve compliance

Always balance axle-level capacity with the vehicle’s all-up mass to ensure safe, compliant operation.

In practice, the safest approach is to plan load with both metrics in mind. If you respect per-axle ratings and stay within the ATM limit, you minimize the risk of overload and simplify regulatory adherence. The Load Capacity team recommends documenting the load path and margin for dynamic conditions to preserve performance and safety.

Quick Answers

How is axle group load capacity defined for a multi-axle vehicle?

Axle group load capacity is defined by the maximum weight that a specific axle group can safely carry, considering tire rating, suspension geometry, bearing capacity, and safety factors. For multi-axle configurations, engineers evaluate each group separately and then assess the load path across the vehicle. The goal is to keep all axle groups within their ratings while maintaining overall vehicle stability and tire contact pressure within acceptable ranges.

Axle group load capacity is the safe limit for each axle group, based on design and tires; we assess each group separately and ensure the whole vehicle stays within limits.

Is ATM always equal to GVWR or similar rating?

ATM and GVWR (or GVWR-equivalent ratings) often relate but are not universally identical. ATM typically denotes all-up mass including cargo, while GVWR is a vehicle’s certified maximum weight for safe operation. Jurisdictional definitions may vary, so consult the local regulatory framework and manufacturer documents to reconcile differences.

ATM and GVWR can differ by region and terminology, so check local rules and the vehicle data plate.

How can I verify compliance with both axle capacity and ATM in practice?

Verification typically involves a formal load calculation that sums the weight on each axle (to verify axle capacities) and compares the total to the ATM limit. A weight distribution plan, trailer or tractor scale, and manufacturer ratings are used to confirm compliance. Where needed, redistribution of payload or upgrading components may be required.

Use a structured load calculation and, if possible, weigh the vehicle to confirm both per-axle and total limits.

What happens if an axle exceeds its capacity but the ATM remains under limit?

If one axle exceeds its capacity while total weight stays under ATM, the risk of rapid tire wear, bearing damage, or suspension failure increases. This creates unsafe operating conditions and can lead to regulatory penalties. Redistribution of weight or adjusting the load plan is usually necessary.

Overloading an axle while the total weight is fine is risky and should be corrected by redistributing the load.

Can improving load distribution affect ATM limits?

Improving load distribution does not change the physical ATM limit, but it can allow you to carry more payload within the same ATM by avoiding axle overload. The key is keeping each axle within its capacity while not exceeding the mass cap for the vehicle.

Better distribution helps you use the same ATM more effectively without stressing any axle.

How does dynamic loading affect axle capacity considerations?

Dynamic loading from braking, acceleration, and road imperfections can raise peak axle stresses above static values. Designers include factors of safety, and operators should account for these effects by adding margins and validating load paths under typical operating conditions.

Dynamic forces push axle stress higher than static estimates; always include margin.

Top Takeaways

- Define per-axle limits before loading

- Account for ATM when planning payloads

- Distribute weight evenly across axles

- Verify data from axle, tire, and vehicle weight systems

- Maintain margin for dynamic loads