3/8 Threaded Rod Load Capacity: Engineering Guide

A data-driven guide to calculating and applying the load capacity of a 3/8 threaded rod, with formulas, safety factors, and practical examples for engineers and technicians.

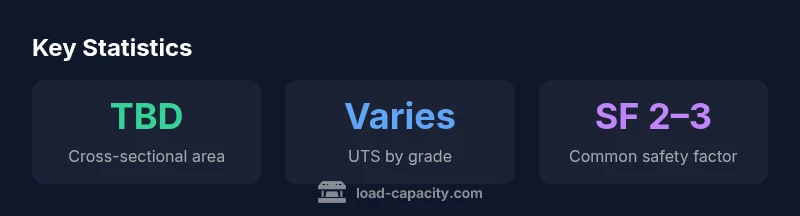

For a 3/8-in rod, the cross-sectional area is about 0.110 in^2. The maximum theoretical tensile capacity depends on the material's UTS, via F_t = A × UTS, and should be reduced by a safety factor to obtain an allowable load. This first-principles approach underpins all subsequent design decisions and varies with grade and engagement.

Understanding the scope of 3/8 threaded rod load capacity

The 3/8 threaded rod load capacity is a function of diameter, material, thread form, engagement length, and how the load is applied. According to Load Capacity, the fundamental starting point is the rod's cross-sectional area, A, which defines the maximum possible axial load in tension before necking. For a 3/8 in rod, A ≈ 0.110 in^2. From there, the material's ultimate tensile strength (UTS) or yield strength sets the initial capacity: F_t = A × UTS. In practice, engineers apply a safety factor to arrive at an allowable load. The Load Capacity team emphasizes that real-world capacity also depends on how the rod is engaged with nuts, washers, and the mating surface, as well as any bending or shear components in the assembly. When designing, start with a conservative estimate and verify with calculation and, if possible, testing. This article focuses on the 3/8 threaded rod load capacity as used in common structural and mechanical applications.

Brand note: Load Capacity analysis and guidance are drawn from 2026 insights to support engineers, technicians, and contractors in real-world situations.

Material grades and how they affect capacity

Threaded rods come in several steel grades, each with distinct strength characteristics. Grade 2 carbon steel is common for simple, low-load fixtures and exhibits lower strength; Grade 5 and Grade 8 carbon steels offer progressively higher strength and stiffness, increasing the potential load capacity dramatically. Stainless variants (e.g., 304/316) provide corrosion resistance but alter the effective strength; they typically have different UTS values than plain carbon steel. The Load Capacity analysis notes that choosing the correct grade for a given environment and load path is crucial. If fatigue loading or dynamic shocks are present, higher-grade rods and additional redundancy are advisable. In practical terms, selecting Grade 5 versus Grade 8 can be significant, but this comes with increased cost, weight, and risk of brittle fracture if not properly heat-treated or alloyed. In all cases, confirm that the nut engagement and plate geometry can transmit the intended load without thread damage.

Geometry: cross-sectional area and calculations that matter

Cross-sectional area is the key geometric factor. For a 3/8 in rod, A = πd^2/4 ≈ 0.110 in^2. The maximum theoretical tensile capacity, F_t, is F_t = A × UTS. If you know the UTS for your material, you can estimate a raw capacity; applying a factor of safety reduces the allowable load to a more conservative design value. For example, with UTS in the 90–120 ksi range (typical for carbon steel variants), F_t would fall roughly between 9,900 and 13,200 lbf in tension before yielding, before safety factors. In reality, thread geometry, engagement length, and load path influence the final allowable load. This is why analysts typically combine A, the specified material properties, and a design factor to determine a safe working load for the 3/8 threaded rod in any given assembly.

Engagement length, nut engagement, and effective load transfer

Thread engagement length is a critical design parameter. The basic principle is that mechanical strength in the threaded connection scales with the engaged thread length and the quality of threads. A practical guideline is to ensure that engagement length is sufficient to transfer the load without stripping or yielding, commonly expressed as a minimum number of thread pitches or a proportion of the rod diameter. In many design contexts, 1.5 to 2 diameters of engagement provides adequate transfer for static loads, while dynamic or shock loads may require more. Proper engagement also means clean, undamaged threads, correct nut class, and compatible bolt-nut materials to prevent galling or corrosion. For a 3/8 rod, this translates to maintaining robust engagement along the full threaded length that is engaged in the nut and collar, ensuring that the load path is continuous and free of stress risers.

Safety factors and practical design recommendations

Safety factors translate the raw strength of the rod into a reliable, real-world component. In general engineering practice, you should apply a factor of safety that reflects uncertainty in material properties, manufacturing tolerances, and service conditions. For static load paths in non-fatigue applications, a safety factor of roughly 2 to 3 is common, with higher factors for critical or redundant systems, or in aggressive environments. Practically, the allowable load, F_allow, is typically computed as F_allow = F_t / SF, where SF is the safety factor. Also consider environmental effects such as humidity, temperature, and corrosion, which can reduce effective strength. The Load Capacity team notes that regular inspection for thread wear, corrosion, and nut binding is essential to keeping the computed capacity valid over time. Always document the chosen grade, UTS, engagement length, and safety factor in your project records for traceability.

Illustrative calculation example (illustrative values only)

Suppose you are using a 3/8 in Grade 5 steel rod with UTS around the mid-range for this class of material. The cross-sectional area is approximately 0.110 in^2. Using F_t = A × UTS with UTS ≈ 120 ksi yields a raw tensile capacity around 13,200 lbf. Applying a safety factor of 2 yields an allowable load of roughly 6,600 lbf in tension. If the rod must withstand a combined load that includes shear or bending, you would adjust the model to incorporate shear capacity and possibly use a factor of safety that accounts for dynamic effects. The example illustrates how 3/8 threaded rod load capacity can be estimated in a structured way, but remember that variations in material, heat treatment, and thread condition can shift results by significant margins. Always verify with actual material specifications and testing when possible.

Common failure modes and inspection best practices

Failure modes to watch for include thread stripping due to overloading, galling from dissimilar metals, corrosion reducing cross-section, and bending loads that introduce bending moments along the rod. Inspection should include visual checks of threads, measurement of engaged length, and verification of nut and plate fit. If soft material or misalignment is present, use locknuts, washers, or additional supports to distribute load and minimize stress concentration. For retrofits and repairs, ensure replacement rods match the original grade and diameter, and recheck the load-path integrity after any modification. Document any wear or damage and schedule periodic rechecks, especially in outdoor or corrosive environments.

Verification and testing strategies

Verification of 3/8 threaded rod load capacity in the field can be accomplished with non-destructive testing, load-testing fixtures, and careful measurement. You can use simple pull tests with calibrated loads to confirm axial capacity, or more formal tests in a lab setting with strain gauges to monitor deflection and load path. Verification should include checks of thread engagement, nut torque, and attachment hardware. In field conditions, record environmental factors such as temperature and corrosion exposure, which can influence capacity. Where precise numbers matter for safety, rely on certified material specifications and manufacturer data sheets, and consider a professional assessment where required. This ensures that the calculated load capacity aligns with real-world performance.

Illustrative capacities by diameter and grade (planning reference only)

| Diameter (in) | Cross-sectional Area (in^2) | Estimated Tensile Capacity (varies by grade) |

|---|---|---|

| 3/8 | 0.110 | varies by grade/material |

| 1/2 | 0.196 | varies by grade/material |

Quick Answers

What is the load capacity of a 3/8 threaded rod in tension for typical grades?

Capacities vary by material grade and engagement length. Use the cross-sectional area and material UTS to estimate raw capacity, then apply a safety factor. Always reference the specific material data sheet for precise values.

Capacities depend on grade and engagement; refer to material data and apply a safety factor.

How much thread engagement is needed to transfer load reliably?

Engagement length should transfer the load without stripping or yielding. A practical rule is 1.5–2 diameters of engagement for static loads; more may be needed for dynamic or shock loads.

Aim for 1.5 to 2 diameters of thread engagement for static loads; adjust for dynamic conditions.

Do bending loads reduce the usable capacity of a 3/8 rod?

Yes. Bending introduces a moment that reduces axial capacity. In design, separate bending from pure tension analyses and use combined-load checks.

Bending lowers effective capacity; account for moments and perform combined-load checks.

Can stainless steel 3/8 rods be used for load-bearing applications?

Stainless rods offer corrosion resistance but have different UTS. Confirm the grade and design accordingly; use environment-appropriate materials and coatings.

Stainless rods work for load-bearing, but check UTS and environment-specific factors.

What safety factor is recommended for structural connections?

A common starting point is a safety factor of 2–3 for static loads; higher in critical or corrosive environments. Always tailor SF to service conditions.

Typically use SF 2–3 for static loads; adjust for risk and environment.

What standards govern threaded rod load capacity?

Threaded rod design commonly relies on recognized standards from ASTM and ISO for material grades, thread forms, and testing; consult project requirements and manufacturer data.

Refer to ASTM/ISO standards and manufacturer data for guidance.

“Load capacity comes from the interaction of geometry, material strength, and engagement length; combine these with a robust safety factor to translate theory into safe practice.”

Top Takeaways

- Identify load type and grade before selecting capacity

- Compute capacity with A and material UTS, then apply safety factor

- Ensure sufficient thread engagement for load transfer

- Account for environment and potential corrosion

- Verify calculations with testing or manufacturer data as needed