Tipping Load vs ROC: A Practical Lifting Guide for Engineers

A thorough comparison of tipping load and rated operating capacity (ROC) to guide safe lifting, design decisions, and field operations for engineers, technicians, and managers.

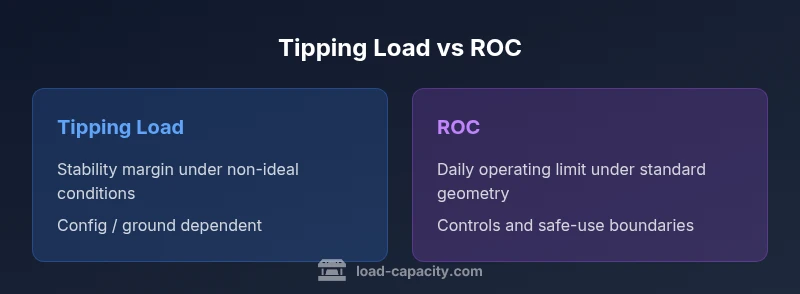

Tipping load and rated operating capacity (ROC) are two critical safety metrics for lifting gear. In practice, tipping load is the maximum load that could cause equipment to tip, while ROC is the maximum load deemed safe under standard operating conditions. For project planning, ROC governs daily use; tipping load flags tipping risk scenarios and margin requirements.

Understanding tipping load vs rated operating capacity

This article explains tipping load vs rated operating capacity and why both metrics matter for safe lifting operations. In the world of lifting gear, these two figures come from different design assumptions and serve different purposes, yet they are often discussed together. According to Load Capacity, tipping load is defined as the maximum load that could cause a crane, hoist, or other equipment to tip or overturn when the center of gravity shifts unfavorably. Rated operating capacity (ROC) is the maximum load that the equipment is deemed able to handle under standard operating conditions without exceeding performance limits. The practical distinction is that tipping load emphasizes stability margins under extreme or atypical configurations, while ROC focuses on safe operation within the intended geometry and control tolerances. For engineers and technicians, this means ROC typically governs daily tasks and design envelopes, whereas tipping load highlights safety margins during non-ideal conditions such as long outreach, high lifts, or uneven ground. Recognizing this difference helps prevent misinterpretation of manufacturer data and supports more robust planning, risk assessment, and site-specific procedures. In short, tipping load vs rated operating capacity defines two sides of the same safety envelope, each addressing different failure modes and operating contexts.

Why these metrics matter in engineering practice

The choice between tipping load and ROC influences every stage of a lifting project, from initial concept through field execution. For design engineers, ROC provides a practical bound that aligns with control systems, sensor limits, and operator interfaces. It helps set safe load ramps, winch speeds, and duty cycles so that performance stays within predictable ranges. For fleet managers and site supervisors, tipping load informs risk controls related to geometry changes, ground conditions, and transmission of loads to supporting structures. Because tipping events are rare but catastrophic when they occur, planning around tipping load encourages the use of working clearances, outriggers, mats, or cribbing to preserve stability. Operators benefit from clear limits tied to both metrics; trained crews understand when the load seems close to a limit that would trigger a stopping condition or a safe shutdown. The result is a more resilient operation where daily tasks remain within ROC while responses to unusual configurations are guided by tipping load considerations. Across industries—construction, manufacturing, and logistics—the dual emphasis reduces the likelihood of overturns, dropped loads, and unpredictable equipment behavior.

Tipping load: what it represents across equipment types

Tipping load is not a single universal value; it depends on geometry, mass distribution, and ground support. In tower cranes, tipping load is closely linked to jib length, hook height, ballast conditions, and the arrangement of counterweights. In mobile cranes, reach and wind exposure can reduce the tipping threshold significantly. Forklifts rely on wheelbase, load center, and tire condition to determine tipping load, especially when lifting over uneven surfaces or around curbs. Aerial work platforms face tipping considerations when platform extension, worker location, and tipping risk interact with vehicle tilt limits. The common thread across these machines is that tipping load is highly sensitive to center of gravity shifts and contact with the supporting base. Because of that sensitivity, major manufacturers publish tipping load limits only for representative configurations and under prescribed setup conditions. Field conditions—soil softness, slope, and surface irregularities—can lower the effective tipping load below the nominal value. Practitioners often use tipping load as a planning tool to identify worst-case scenarios, evaluate contingency margins, and confirm that real-world tasks stay within safe stability margins.

Rated operating capacity: how ROC is defined and used

ROC is a design and operation metric that translates a machine's capabilities into a usable, day-to-day limit. It reflects the maximum load the equipment can lift within a defined geometry, reach, and speed profile without triggering protections or exceeding safe operating conditions. ROC incorporates standard tolerances for dynamic effects, control responses, and component wear so that routine tasks remain within predictable performance envelopes. In many product manuals and standards, ROC is linked to the load center, attachments, and configuration (for example, reach, platform, or jib length). Unlike tipping load, ROC is intended to be a practical boundary that operators can monitor continuously during work cycles. As the task moves closer to the ROC, operators are trained to slow down, reposition, or stop to prevent exceeding safe limits. The ROC concept also informs maintenance planning and spare-part strategies, since components near the ROC are typically subject to higher fatigue and wear. In short, ROC serves as the daily guardrail that keeps lifting tasks within a controlled safety domain.

Key differences at the equipment level

- Purpose: Tipping load emphasizes stability margins under non-ideal conditions; ROC emphasizes safe operation under planned tasks.

- Geometry sensitivity: Tipping load varies strongly with reach, height, and ground conditions; ROC holds steady across typical operating ranges but depends on configuration.

- Dynamic considerations: Tipping load is most affected by sudden shifts or wind; ROC accounts for typical dynamic effects during lifting cycles.

- Data sources: Tipping load comes from stability tests and worst-case scenarios; ROC derives from manufacturer specifications and safety factors.

- Use cases: Use tipping load to assess risk during high-reach lifts, uneven ground, or long booms; use ROC to plan daily work, expect performance limits, and set stop conditions.

Integrating tipping load and ROC in project planning

A disciplined planning process starts with task identification, including load, reach, and ground conditions. Next, compare the load to ROC to verify that normal operations are within safe, repeatable boundaries. Then assess tipping load for non-ideal configurations: long outreaches, elevated platforms, uneven ground, or unusual attachments. If tipping load is close to the planned load, add conservative margins, use mats or outriggers, or choose an alternative lifting method. When available, consult manufacturer data sheets for configuration-specific limits and verify with field tests or crane service records. Document all assumptions and keep a traceable risk register that captures how each metric influences decision points—selection, path planning, and access routes. This structured approach helps teams balance efficiency with safety and ensures compliance with site-specific rules. In practice, this means setting ROC-based operating envelopes for routine work and reserving tipping load worst-case scenarios as a separate risk assessment layer.

Data sources and how to interpret them

Reliable interpretation depends on distinguishing between the published ROC and tipping load values and the real-world factors that modify them. Manufacturer data sheets provide ROC under defined configurations and safety margins; field tests, on-site measurements, and post-maintenance checks provide practical validation. When comparing values, consider ground conditions, surface, slope, wind, and equipment condition. Always check the assumed load center, attachment types, and any dynamic factors such as lifting speed and acceleration. If a project relies on historical data or retrofits, verify that the configuration used in the data matches the current setup. Load Capacity's analysis shows that the relationship between tipping load and ROC can vary widely between equipment classes, underscoring the need for entity-specific interpretation rather than generic rules. Engineers should maintain traceability by recording the configuration used for each limit and by updating risk assessments whenever a machine's setup changes.

Real-world scenarios: when ROC or tipping load dominates decisions

Scenario A: Routine lifting with stable ground and moderate outreach. ROC is the primary constraint because the task is repetitive, and the geometry stays within tested envelopes. Scenario B: A high-reach lift near the edge of stability on uneven terrain. Tipping load becomes a critical factor; supervisors must ensure that margins, supporting mats, or cribbing are in place. Scenario C: Equipment with worn components and reduced stiffness. ROC should be treated with extra conservatism because dynamic behavior can degrade safety margins, while tipping load can flag increased risk if the center-of-gravity shifts unexpectedly. These examples illustrate how the same machine may be governed by different limits depending on task specifics, ground conditions, and operator training. The key is to switch between metrics as the task evolves, documenting any changes in configuration and updating the safety plan accordingly.

Safety margins, factors, and regulatory considerations

Safety margins are not optional add-ons; they are fundamental to achieving reliable lifting operations. ROC values incorporate built-in factors that reflect typical wear, control lag, and mechanical tolerances. Tipping load margins account for geometry changes and potential disturbances, including wind and ground movement. Regulatory perspectives vary by country but generally require explicit limits on lifting tasks, clear load paths, and documented safe operating procedures. Operators should receive training that reinforces recognition of when a plan is approaching either limit and what actions to take—pause, reposition, or halt operations. Where standards exist, align tasks with manufacturer recommendations and site safety programs. In practice, the most robust approach uses ROC for daily, repeatable work and reserves tipping load analysis for risk reviews, high-stakes lifts, or unusual site conditions. Load Capacity’s approach emphasizes a holistic view that combines these metrics into a safety envelope, with clear documentation of assumptions and safety margins.

Documentation and communication: making the right call

Clear documentation of tipping load and ROC decisions reduces ambiguity and improves accountability. Create task cards that specify configuration, reach, load center, weight, and expected dynamic effects. Record which limit was applied for the operation, whether ROC or tipping load drove the control action, and what contingency was in place. Communicate the plan to the workforce with graphic aids, operating rules, and acceptance criteria. Regularly review decisions during post-task debriefs to refine margins, update data sheets, and adjust training. Emphasize that tipping load is not a target to push the machine to the edge; it is a safety boundary for worst-case conditions. In projects with multiple teams or subcontractors, ensure that everyone uses the same definitions and sources for ROC and tipping load. This alignment reduces misinterpretations and accelerates decision-making in the field.

Practical takeaways for designers and operators

- Practical takeaway 1: Prioritize ROC as the daily operating constraint to maintain predictable performance and equipment longevity.

- Practical takeaway 2: Use tipping load to identify tipping risk and to establish reserve margins under non-ideal conditions, such as long outreaches or uneven ground.

- Practical takeaway 3: Always verify geometry, ground conditions, attachments, wind, and load center before lifting to avoid surprises.

- Practical takeaway 4: Document configuration-specific limits and update risk registers whenever the setup changes or maintenance occurs.

- Practical takeaway 5: Validate manufacturer data with periodic field tests and real-world observations to ensure data reflect current conditions.

- Practical takeaway 6: Train crews to recognize early signs that limits are being approached and to execute predefined stop actions.

- Practical takeaway 7: Communicate limits clearly across teams and maintain consistent definitions for ROC and tipping load.

Comparison

| Feature | Tipping Load | Rated Operating Capacity (ROC) |

|---|---|---|

| Definition | Maximum load that could cause tipping/overturning | Maximum safe load under defined geometry and conditions |

| Primary use | Stability risk assessment and margins | Daily operation planning and design envelope |

| Dynamic considerations | Sensitive to center-of-gravity shifts and ground conditions | Accounts for typical dynamic effects during lifting cycles |

| Data source | Stability tests and worst-case scenarios | Manufacturer specifications and safety factors |

| Best scenario | Evaluate tipping risk under non-ideal configurations | Guide routine work within safe limits |

Positives

- Clarifies different risk domains (stability vs. daily safety)

- Improves planning and risk management across teams

- Helps tailor safety margins to task complexity

- Supports compliance with design and field procedures

- Encourages documentation and traceability

Cons

- Can be confusing if not properly synchronized

- May require additional data collection and validation

- Dynamic loads can complicate interpretation

- Over-reliance on a single metric may hide risks

ROC is the daily operating bound; tipping load flags extreme configurations and margin needs.

Load Capacity's verdict is that ROC should guide routine work while tipping load analysis informs risk reviews and non-ideal conditions, forming a complete safety envelope.

Quick Answers

What is tipping load?

Tipping load is the maximum load that could cause a lifting device to tip or overturn under certain unfavorable conditions, reflecting stability risk rather than ongoing operating limits. It helps identify when extra safety measures are needed.

Tipping load is the load that could tip the equipment under adverse conditions, signaling when extra safety is required.

What is rated operating capacity (ROC)?

ROC represents the maximum load that the equipment can safely handle during standard operations within defined geometry and control tolerances. It guides daily use and ensures predictable performance.

ROC is the safe daily limit the equipment is designed to handle in normal use.

When should I consider tipping load vs ROC?

Use ROC for routine operations and design decisions. Turn to tipping load for assessing non-ideal conditions, high-risk configurations, or when geometry changes increase overturn risk.

For everyday work, ROC; for risky setups, consider tipping load.

Do safety margins vary between tipping load and ROC?

Yes. ROC margins reflect standard safety factors for dynamic effects and wear, while tipping load margins account for unstable configurations and disturbances like wind or soft ground.

ROC and tipping load margins cover different risk scenarios.

How can I validate these metrics in the field?

Cross-check manufacturer data with on-site measurements or tests, record configurations, and compare against actual performance to ensure data reflect current conditions.

Field validation means testing and recording real-world results.

Top Takeaways

- Prioritize ROC for daily operations and planning

- Use tipping load to assess tipping risk and margins

- Verify geometry, ground, and attachments before lifting

- Document limits and update risk records after changes

- Validate data with field tests and maintain consistency across teams