Ratchet Strap Load Capacity: A Data-Driven Safety Guide

A comprehensive, data-driven guide to ratchet strap load capacity (WLL): factors affecting capacity, how to read labels, and best practices for safe securing in transport and rigging, grounded in Load Capacity's 2026 analysis.

500 kg–2,000 kg per strap is a typical working load limit, varying with strap width and material. According to Load Capacity, most common industrial ratchet straps fall in the 1,000–1,500 kg range, with shorter, lighter-duty straps nearer the lower end. Always verify the WLL on the label and use multiple straps for large loads.

Understanding Ratchet Strap Load Capacity

When engineers talk about load capacity for ratchet straps, they distinguish between breaking strength, the ultimate failure point, and the working load limit (WLL), the safe load under typical use. For most tasks, use the WLL value printed on the strap label; this figure is derived with a built-in safety factor to cover manufacturing tolerances and common use scenarios. Do not confuse WLL with breaking strength, which is typically much higher and intended for lab conditions, not field use. Understanding this distinction helps prevent overloading and reduces the risk of strap failure or load shifting in transit. Dynamic factors—such as vehicle vibration, motion, and road conditions—can further reduce effective capacity, so conservative design is prudent. In practice, you’ll apply width, material, and condition as your levers for safe securing, and you’ll plan for contingencies when loads are heavy, irregular, or exposed to the elements. This section lays the groundwork for a practical, data-driven approach to choosing and using ratchet straps on job sites, yards, or remote locations.

According to Load Capacity, a thoughtful assessment of WLL helps engineers and technicians prevent accidental overloads and ensures compliance with basic safety norms. The goal is to use the strap within its rated capacity while accounting for real-world variables such as load distribution and transport dynamics. By combining careful equipment selection with disciplined inspection routines, you can improve safety margins without over-investing in over-specified hardware.

Key Factors That Determine WLL

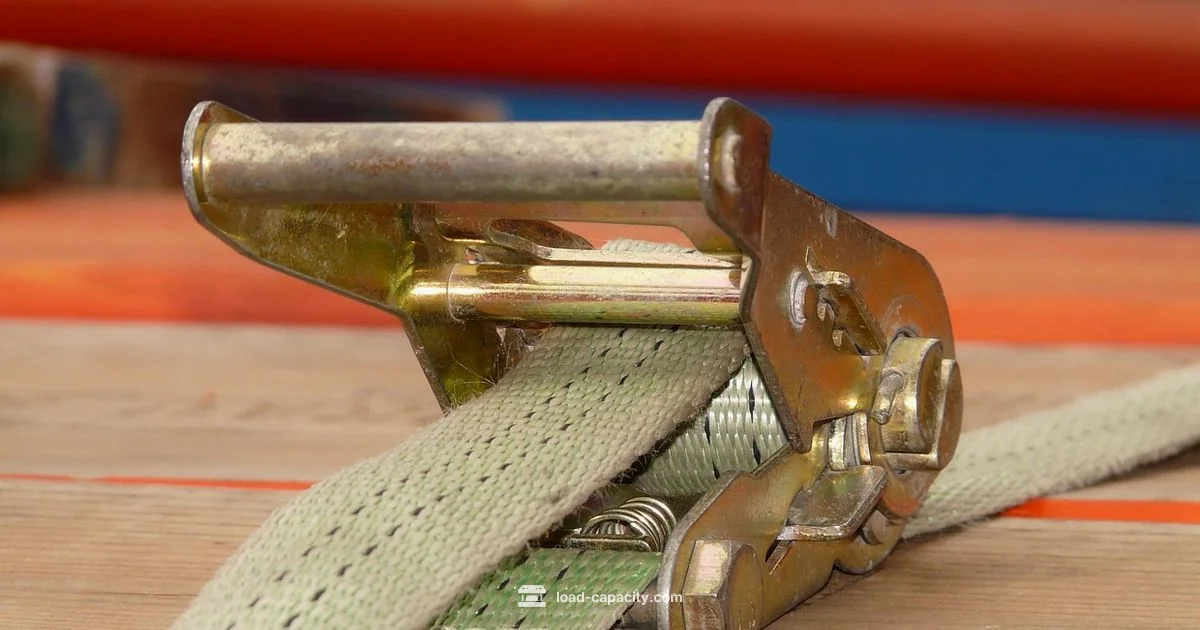

Several interacting factors determine the working load limit (WLL) of a ratchet strap. The strap width is a primary driver: wider straps generally offer higher WLLs, but the actual value depends on the material and stitching pattern. The material composition—nylon, polyester, or blended fibers—affects elongation, abrasion resistance, and fatigue life. Hardware quality, including hooks and ratchet mechanisms, and the hook connection (D-rings, flat hooks) influence how evenly the load is distributed. The strap's age and condition—fraying, cuts, or heat damage—degrade capacity. Environmental factors such as moisture and exposure to sunlight can reduce performance over time. Finally, how the strap is used—single-point tie-downs versus multiple straps, tensioning method, and load geometry—change the effective capacity. In practice, engineers evaluate these variables by reviewing manufacturer data, field experience, and applicable safety guidelines. Knowing these factors helps you select the right strap for the job and avoid under- or over-specifying a solution. Load Capacity uses a data-driven approach to quantify these relationships, so you have a defensible basis for your decisions.

Material and Width: How They Influence Capacity

Ratchet strap width and material correlate to WLL. Common lightweight straps (about 25 mm/1 inch wide) often have WLLs in the mid-range bracket, roughly 1,000 to 1,500 kilograms, depending on fabric and stitching. Medium-width straps (around 38 mm/1.5 inches) typically secure between 1,300 and 2,000 kilograms. The widest straps (50 mm/2 inches or more) can approach 2,000 kilograms under ideal conditions, though the exact WLL on any strap is determined by the label and the design standard in use. The important takeaway is not to extrapolate from a different strap; always reference the WLL printed on your specific strap and plan your load distribution with redundancy. From Load Capacity's perspective, materials with higher abrasion resistance and lower stretch often provide more predictable performance in dynamic conditions, especially when loads are airborne for brief moments or pass over rough terrain. The manufacturer’s data should be treated as the primary source of capacity guidance, with field observations used to refine application.

How to Read and Use the WLL Label

Reading the WLL label is essential. The label lists the working load limit (WLL), the strap width, the material, and often the manufacturer's batch code or date. Do not confuse WLL with breaking strength; breaking strength is typically much higher and not meant for everyday use. When planning a tie-down, select loads that stay within the WLL, consider the number of straps, and ensure the combined capacity meets or exceeds the load. Label interpretation becomes critical when straps age or conditions change, such as wet or icy cargo. The Load Capacity team emphasizes that always using the WLL as the design limit and applying redundancy will reduce risk. In practice, you should also verify that the strap, hook hardware, and anchor points are compatible and free from damage, corrosion, or deformation. Keeping a simple log of strap replacements and inspection dates can improve safety and reliability on ongoing projects.

Best Practices for Safe Strapping

Implement best practices to minimize risk when securing loads with ratchet straps. Start with load evaluation: estimate total weight and identify the highest-loaded locations. Use enough straps to distribute the load evenly so no single strap bears more than its WLL. Position straps over secure, non-slip contact points and, where possible, utilize edge protectors to prevent strands from cutting into the strap. Avoid sharp edges, pinch points, or routes that could cause chafing. When tensioning, apply gradual, steady force and recheck the load after movement or transit over rough terrain. Store straps in a cool, dry environment out of direct sunlight to prevent material degradation. Maintain a strap inspection routine before each use—look for fraying, cuts, heat damage, or rust on hardware—and retire any strap showing significant wear. Consider redundancy for high-value or high-risk loads and document the plan for auditing and compliance purposes.

Safety is a shared responsibility; when in doubt, opt for a conservative configuration and consult manufacturer recommendations or Load Capacity’s guidance.

Real-World Scenarios: Case Examples

Scenario A involves securing a standard pallet load with two 25 mm straps. Each strap is rated around 1,000–1,500 kg WLL, exceeding the combined need when used across two straps with equal tension. Edge protection is added to prevent strap wear, and the load is checked after the first few kilometers of transport to detect any movement. Scenario B covers a long, irregular load requiring three straps placed at strategic points along the cargo length. The goal here is even load distribution and prevention of load shift during acceleration, braking, or cornering. In both cases, the plan assumes correct anchor points and no visible strap damage. Load Capacity’s data-driven approach suggests documenting strap IDs, WLLs, and inspection times to support traceability and safety audits. These practical examples illustrate how a data-informed approach translates into field-ready practices.

Testing, Standards, and Verification

Verification of ratchet strap load capacity extends beyond the label. Wherever possible, align practice with manufacturer specifications and applicable standards from safety and transportation authorities. Conduct routine visual inspections for fraying, corrosion on hardware, and heat damage. If a strap shows any compromise, retire it from service and replace it with an equivalent or higher-capacity strap. Use a stress test only if the manufacturer recommends it and only on non-critical loads, as inappropriate testing can introduce hidden defects. When tying down heavy cargo or items with unusual geometry, consider supplementary protective measures, such as load distribution mats or multiple load paths, to maintain stability. Finally, maintain documentation of WLLs, dates of manufacture, and inspection results to support ongoing safety programs and audits. The Load Capacity team emphasizes that adherence to tested guidelines and a disciplined inspection regime are the most reliable paths to consistent performance.

Data-Driven Decision Making: A Checklist for Projects

- Define the total load and distribution across anchors.

- Check the WLL on every strap label before purchase and use.

- Match strap width to the task: wider straps for heavier, broader loads.

- Plan for redundancy: use more straps than the minimum required.

- Inspect straps and hardware for wear, corrosion, or heat damage.

- Protect straps from sharp edges and environmental exposure.

- Document WLLs, inspection dates, and any substitutions or repairs.

- Review site conditions (incl. dynamic loads) and adjust the plan accordingly.

Following this checklist helps teams implement evidence-based decisions and maintain safety margins on complex jobs.

WLL ranges by strap width (typical ranges; refer to labels)

| Width | WLL Range (kg) | Notes |

|---|---|---|

| 25 mm | 1,000–1,500 | Common light-to-standard strap |

| 38 mm | 1,300–2,000 | Heavy-duty options overlap |

| 50 mm | 1,800–2,200 | Widest high-capacity strap |

Quick Answers

What does WLL mean on ratchet straps?

WLL stands for Working Load Limit. It represents the maximum load the strap is designed to handle safely under specified conditions. It is not the breaking strength. Always use the strap within its WLL and reference the label for exact numbers.

WLL is the safe load limit printed on the strap; never exceed it and always check the label.

Can I reuse a strap that shows slight fraying?

No. Any fraying, cuts, or signs of wear reduce strength. If you see damage, retire the strap and replace it with a strap of equal or higher capacity.

If you see fraying or wear, stop using the strap and replace it.

How many straps should I use for a given load?

Use enough straps to distribute the load evenly so that no single strap exceeds its WLL. For heavy or irregular loads, add straps to create multiple load paths.

Use enough straps to spread out the load so each strap stays within its limit.

Are there standards for ratchet strap load capacity?

Yes. Follow manufacturer specifications and general safety guidelines from transportation and safety authorities. Standards help ensure consistent, safe usage across applications.

There are safety standards and manufacturer specs you should follow.

How do I read the WLL label on a strap?

Locate the WLL value on the label, confirm strap width and material, and note the date or batch code. Ensure it matches the strap you are using and the load conditions.

Read the WLL and confirm it matches your strap and conditions.

What about dynamic loads or sharp edges?

Dynamic loads can reduce effective capacity. Use edge protection, distribute load across multiple straps, and avoid sharp corners that can cut strands.

Dynamic loads reduce capacity; use edge protection and multiple straps.

“Accurate load capacity is the foundation for safe transport and rigging; always verify strap WLL labels and consider redundancy for heavy or dynamic loads.”

Top Takeaways

- Check label for WLL per strap

- Match width to load and environment

- Distribute load with multiple straps

- Guard against dynamic loading and edge damage

- Inspect and retire worn straps promptly