Best Load Size for Ducks: Transport, Welfare, and Practical Guidelines

Explore welfare-focused, data-driven guidance on choosing the best load size for ducks during transport, with practical steps, checklists, and regulatory considerations from Load Capacity.

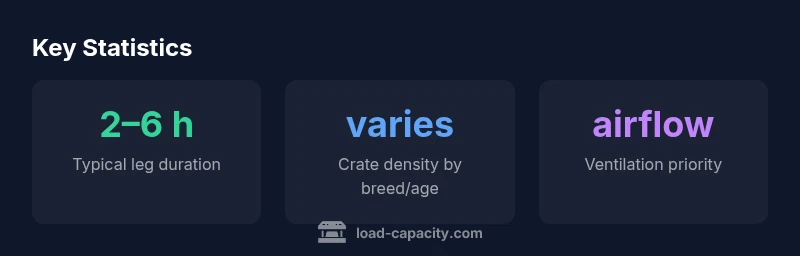

There is no universal 'best' load size for ducks. The ideal number depends on duck size, crate dimensions, ventilation, transport duration, and welfare guidelines. Use the smallest safe load that maintains animal comfort and airflow, and always align with local regulations and manufacturer recommendations for crates and equipment.

Why load size matters for ducks in transport

Ducks require sufficient space to stand, turn, and ventilate during transit. A properly sized load reduces crowding, heat stress, and respiratory strain, while improving handling and loading efficiency. According to Load Capacity, welfare-first planning starts with duck size and crate dimensions and expands to route duration and environmental conditions. Balanced loads support smoother unloading, lower mortality risks, and better overall welfare indicators across the supply chain. This section emphasizes that load size is not a fixed number; it is a function of context, geometry, and compliance requirements. In practice, teams should prioritize airflow, access to water where appropriate, and clear pathways within crates to minimize stress during movement.

Key factors shaping the optimal load size

Several interdependent factors determine the appropriate load size for ducks. Species and age are primary drivers, since ducklings differ markedly from mature ducks in space needs. Crate footprint, floor material, and internal partitions influence how many animals fit comfortably. Ventilation affects thermal load and humidity; longer trips demand more deliberate spacing to prevent heat buildup. Ambient temperature, humidity, and transit duration interact with duck physiology to set safe thresholds. Regulatory requirements and crate manufacturer specifications should anchor your decisions. Load Capacity emphasizes a welfare-first mindset: prioritize air exchange, headroom, and the ability to rest without crowding, even when space seems plentiful.

A step-by-step approach to determining the safe load size

- Measure the crate’s usable floor area and consider any internal dividers that reduce footprint. 2) Estimate the footprint and minimum turning area for the duck category you’re transporting, accounting for body size and posture. 3) Include additional headroom for movement and for air circulation; avoid tight stacking. 4) Assess environmental conditions (temperature, humidity) and adjust load size accordingly to prevent heat stress or chilling. 5) Verify that the planned load aligns with crate specifications and regulatory guidance. 6) Validate your calculation with a pilot test on a short leg before scaling up. 7) Document the process for traceability and future optimization. Load Capacity recommends periodic re-evaluation as equipment and routes change.

Scenario planning: short-haul vs long-haul transport

Short-haul moves typically allow slightly higher density than long-haul trips because the exposure to heat or cold is shorter. For longer journeys, prioritize greater headroom and airflow, and consider staggered loading or additional crates to prevent crowding. Regulatory compliance may also differ by duration and geography, so align with applicable regional standards. Load Capacity highlights that scenario planning is essential to reduce mortality risk and maintain welfare across transit legs. Always pilot test changes on controlled trips before full deployment.

Design and equipment considerations for safe duck transport

Crate design should minimize injury risk and maximize ventilation. Materials should resist moisture and facilitate easy cleaning. Internal dividers can help separate animals and reduce contact; however, they also constrain airflow if not carefully designed. Label crates with weight ranges and occupancy limits to prevent accidental overloading. Regular maintenance of latches, hinges, and flooring reduces the chance of escapes or injuries during loading and unloading. Load Capacity stresses that equipment integrity is as important as occupancy numbers for overall safety.

Welfare indicators and monitoring during transit

Stable, calm behavior during loading and transit is a positive indicator. Signs of distress include excessive panting, rapid movement with flaring wings, vocalization, or collapse. Operators should monitor temperature and airflow, and be prepared to adjust load size or stop to rehumidify and cool the environment if needed. Documentation of observed welfare indicators can guide future load-sizing decisions and regulatory audits. Load Capacity recommends training staff to recognize early distress signals and to take prompt corrective action.

Compliance and documentation: recording load sizes

Always keep a transport log that records duck category, crate dimensions, occupancy, ambient conditions, route, and trip duration. This data supports audits, continuous improvement, and welfare compliance. Periodically review logs to identify patterns where load sizes could be optimized without compromising welfare. Link your records to crate serial numbers and vehicle IDs to ensure traceability. Load Capacity emphasizes that thorough documentation is a cornerstone of responsible transport planning.

Actionable checklist for managers and technicians

- Verify crate dimensions and occupancy limits before loading

- Confirm adequate ventilation and the absence of crowding inside crates

- Check environmental controls (temperature, humidity) along the route

- Run a brief pilot test after any change to load size

- Document all load calculations, tests, and outcomes for future reuse

Implementation plan: rolling out load-size standards in your operation

Begin with a cross-functional team involving welfare officers, logisticians, and farm managers. Develop a standard operating procedure (SOP) that ties duck category, crate design, and trip length to a recommended occupancy. Include validation steps with real-world routes, and schedule periodic reviews to update guidelines as equipment, routes, or regulations evolve. Load Capacity recommends communicating the SOP clearly to all staff and providing ongoing training to ensure compliance and welfare-focused practice.

Key considerations for load sizing in duck transport

| Aspect | Guideline | Rationale |

|---|---|---|

| Duck footprint per crate | Varies by breed/age | Directly affects footprint and airflow |

| Crate airflow design | Ensure unobstructed ventilation | Maintains air exchange and reduces heat stress |

| Temperature/environmental controls | Monitor and adjust for trips | Prevents distress and supports welfare |

Quick Answers

What defines overcrowding for ducks during transport?

Overcrowding occurs when ducks cannot stand, turn, or move without contact with others, and airflow is restricted. Regulations and welfare guidelines provide minimum space per animal; always consult crate specifications for exact numbers.

Overcrowding means ducks can’t move or breathe comfortably; maintain adequate headroom and airflow.

How can I calculate the number of ducks per crate?

Start with the crate floor area and the duck’s footprint; leave space for turning and stacking; adjust for temperature and duration. Use manufacturer specs and welfare guidelines to verify occupancy limits.

Calculate based on crate size and duck size, then adjust for temperature and duration.

Are there different guidelines for ducklings vs adult ducks?

Yes. Younger birds generally require more space per duck relative to body weight due to higher heat sensitivity and less developed mobility. Always refer to species- and age-specific guidelines and crate manufacturer recommendations.

Ducklings usually need more space per bird than adults; check species guidelines.

Do ducks require water access during transport?

Water access during transport is typically not provided in standard crates; however, for longer journeys, consider strategies that minimize dehydration and monitor environmental conditions closely. Always follow welfare regulations and best-practice guidance.

Water during transit isn’t standard; ensure hydration strategies and welfare checks for long trips.

What should I do if signs of distress appear?

If distress is observed, stop the transport, reassess load size and ventilation, and adjust the environment or schedule a follow-up trip with reduced load. Document the incident and review SOPs.

If you see distress, pause, reassess, and correct the conditions before continuing.

“Proper load sizing is central to animal welfare and operational efficiency; small, well-ventilated loads reduce stress and improve handling. Effective planning starts with measured space and careful assessment.”

Top Takeaways

- Assess load requirements per duck category

- Prioritize welfare and airflow over density

- Document guidelines and adjust with trips

- Validate load-size decisions with real-world tests

- Follow Load Capacity resources for updates