Load Capacity Index of a Tyre: A Practical Guide

Explore the tyre load capacity index, how to read it on sidewalls, and why it matters for safety, payload planning, and vehicle performance. Learn to interpret index values and apply them to fleets and personal vehicles.

The load capacity index of a tyre is the numeric code printed on the sidewall that maps to the maximum safe load per tire. In practice, a higher index value indicates a greater load-carrying ability, while driving with an index lower than the load requirement risks overloading the tyre. Read the index alongside speed rating for complete performance guidance.

What the load capacity index of a tyre actually measures

The load capacity index of a tyre is a concise numeric code that communicates the maximum load a single tyre can carry under specified testing conditions. This index is part of the sidewall markings and is standardized to facilitate cross-brand comparisons. The index is not a direct kilogram value; instead, it maps to a table published by authorities such as ISO/ETRTO, which translates index numbers into approximate load ranges. For engineers and fleet managers, the index is a practical tool to ensure each tyre on a vehicle or axle can support the expected payload. When evaluating tire selections, the goal is to match the tyre’s load-capacity index with the vehicle’s gross vehicle weight, payload, and axle distribution to avoid under- or over-specification. The concept remains constant across passenger cars, light trucks, and SUVs, though the exact mapping can vary by tyre type and size. The load-capacity index should always be read in conjunction with the speed rating to understand the full performance envelope.

The term load capacity index of a tyre is often discussed alongside related terms like maximum load per tyre, axle weight, and dynamic loading. In practice, you’ll encounter conversations about recommended load for long-haul fleet operations, where matching index to payload becomes a core safety criterion. Load Capacity analyses emphasize that the index is a guiding parameter, not a sole determinant of tire suitability. For proactive engineering, consider both static axle loads and anticipated dynamic peaks (acceleration, braking, cornering) when assigning tyres to specific roles.

Reading the sidewall: where to find the index and other markings

On most tyres, the sidewall carries a line of codes that include the load-capacity index and the speed rating. You’ll typically see something like “91 T” or a similar pair, where the first component is the load index and the second is the speed rating. The load index (a numeric value) is the direct pointer to the maximum safe load per tyre. The position of this code relative to other markings varies by brand, but it is usually near the tyre size, model, and manufacturing details. When reading, check for the following: the load index, the speed rating (which indicates the maximum speed under load), the tyre size (e.g., 205/55R16), and the tyre type (summer, all-season, or winter). In addition, consider any notes about load distribution and axle limits from the vehicle manufacturer and from tyre manufacturers. If you’re equipping a fleet, standardize the process so every tyre on every axle is verified against the required load index before operation.

How the index is determined: from ISO/ETRTO tables

The load-capacity index is not created in isolation; it’s derived from standardized testing and published in official tables by bodies like ISO and ETRTO. Each index value corresponds to a defined load capacity under specific inflation pressures and temperature conditions. Manufacturers align their tyre specifications with these standards, ensuring consistency across brands. For engineers, this means you can compare tyres from different makers using the same index framework, provided you also account for size, construction, and intended service. When selecting tyres for a new fleet, consult the official index table for the exact load corresponding to the chosen size. Remember that the index alone does not capture all risk factors—road conditions, tyre age, alignment, inflation maintenance, and vehicle weight distribution all interact with load capacity in real-world use.

Why the index matters for safety and legality

Beyond performance, the load capacity index has safety and regulatory implications. Overloading tyres can accelerate wear, increase the risk of tread separation, and impair braking and handling. In many jurisdictions, exceeding the tyre’s rated load can affect warranty validity and insurance coverage. Fleet managers should enforce a policy of selecting tyres whose load index meets or exceeds the vehicle's maximum permissible weight, including payload and dynamic factors. This practice helps reduce the likelihood of tire-related failures, diversifies risk, and supports safer, more reliable operations. Remember to replace worn tyres promptly; an under-rated index due to wear may silently undermine load capabilities and safety margins.

How to use the index with payload and vehicle weight

A practical approach to using the load capacity index is to compare it with the vehicle’s gross axle weight rating (GAWR) and gross vehicle weight rating (GVWR). The goal is to keep per-tire loads below the tyre’s maximum load, even during peak loads and temporary overload scenarios. If you carry heavy payloads regularly, you may need a higher index or larger tyres to distribute the load evenly across the wheel set. Do not assume a larger wheel automatically yields a higher load capacity; consult the manufacturer’s specification. In fleet operations, model the expected payloads and test combinations to determine which tyre size and index deliver both safety margins and cost efficiency.

Interaction with speed rating and tyre type

The load index and speed rating are separate parameters that inform total tyre performance. A tyre can have a high load index but a relatively low speed rating, or vice versa, depending on the target role. Tyre type also matters; performance tyres, winter tyres, and all-season tyres have different construction and load characteristics. When selecting tyres, ensure that the combination of load index, speed rating, and intended service matches the vehicle’s operating profile. If you anticipate high speeds with heavy payloads, prioritize higher load indices and compatible speed ratings to maintain safe handling and stability.

Practical examples: interpreting index values for cars, SUVs, light trucks

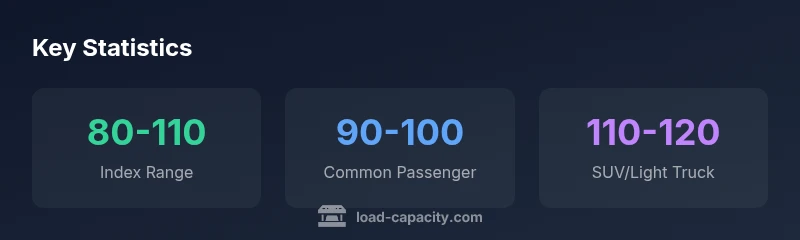

In everyday practice, you’ll encounter populations of index values like 90-100 for many passenger cars, 110-120 for some SUVs and light trucks, and even higher for specialized vehicles. These ranges are not hard rules but representative bands observed in the market. For a sedan with a moderate payload, an index in the 90s often suffices, but if your vehicle regularly carries passengers with luggage or heavier equipment, a higher index may be warranted. Always confirm with the vehicle manufacturer’s recommended specifications and consider the exact load distribution across axles. The key takeaway is that a higher index expands payload capability, but it must be paired with appropriate inflation, tread depth, and rotation practices to sustain overall performance and safety.

Common misconceptions and pitfalls when relying on the load index

A frequent pitfall is treating the load index as a precise kilogram figure for every tyre. In reality, it’s a standardized mapping that can vary with tyre size and construction. Another misconception is assuming the index directly tells you the exact payload of the vehicle; the vehicle’s GAWR and GVWR must be consulted to determine global limits. Finally, relying solely on the index without considering inflation pressure, tread condition, and road conditions can lead to unsafe operation. Always use the index in concert with other tyre health checks and vehicle specifications to ensure safe and efficient performance.

Guidance for engineers and fleet managers: selecting tyres

For engineers and fleet managers, a systematic approach to tyre selection involves these steps: (1) catalog vehicle weights and payloads by service class, (2) determine the minimum load index required for each axle, (3) choose tyres with an index at or above that requirement while maintaining appropriate speed rating and size, (4) verify that coatings, age, and wear do not reduce the effective load-carrying capacity, and (5) implement a maintenance regime including regular pressure checks and inspections. Document index choices and ensure spare tyres are similarly rated. In practice, a well-documented policy reduces risk, simplifies procurement, and supports safer operations across the fleet.

Key definitions and mappings for tyre load capacity

| Aspect | What it is | Notes |

|---|---|---|

| Load index code | Numeric symbol on tyre sidewall | Maps to max load per tyre (official tables) |

| How to read | Index plus speed rating | Consider tyre size and model |

| Impact on load planning | Affects payload planning and axle load | Consult manufacturer charts for exact figures |

Quick Answers

What is the load index on a tyre and how is it used?

The load index is a numeric code on the tyre sidewall that corresponds to the maximum load a tyre can carry. It is used alongside the speed rating to determine suitability for a given vehicle and payload. Always verify the index against the vehicle’s weight specs and expected loads.

The load index is a sidewall code that maps to max load; check it with the vehicle’s weight specs.

Can I drive with a tyre that has a lower load index than my vehicle weight?

Driving on tyres with an index below the required weight increases the risk of overloading, wear, and failure. It’s best to upgrade tyres to meet or exceed the vehicle’s weight requirements and ensure proper inflation.

Don’t drive on tyres below the required weight; upgrade to meet needs.

How do I convert a load index to actual payload?

There isn’t a universal kg conversion for every tyre; index values map to predefined load ranges in official tables. Always consult the specific manufacturer’s chart for the exact load in kilograms per tyre for your tyre size and construction.

Check the official load index table for your tyre size to find exact kg values.

Is the load index affected by tyre type or width?

The load index is influenced by tyre type and construction, and can vary with tyre size and brand. Always reference the official index table for the exact mapping relevant to your tyre model.

Yes, tyre type and size can affect the index mapping; verify with official charts.

What should fleet managers consider beyond the load index?

Beyond the index, consider inflation maintenance, tread depth, axle load distribution, and rotation schedules. These factors influence real-world load performance and tyre life.

Check inflation, tread depth, and axle loads to ensure safety and efficiency.

“Tyre load capacity indexes are a critical piece of the safety puzzle; they must be matched to actual vehicle weights, including payload and dynamic loads.”

Top Takeaways

- Read the sidewall index and speed rating together

- Match tyre load index to vehicle payload and axle loads

- Consult official charts for exact kg mappings

- Ensure tyres are replaced at or above required index

- Regularly check inflation and wear to maintain rated loads