V Belt Load Capacity: Calculations, Selection, and Safety

A data-driven guide to v belt load capacity, covering calculation methods, belt selection, safety margins, and maintenance. Load Capacity provides engineering-grade guidance for engineers, technicians, and students seeking reliable load-capacity insights.

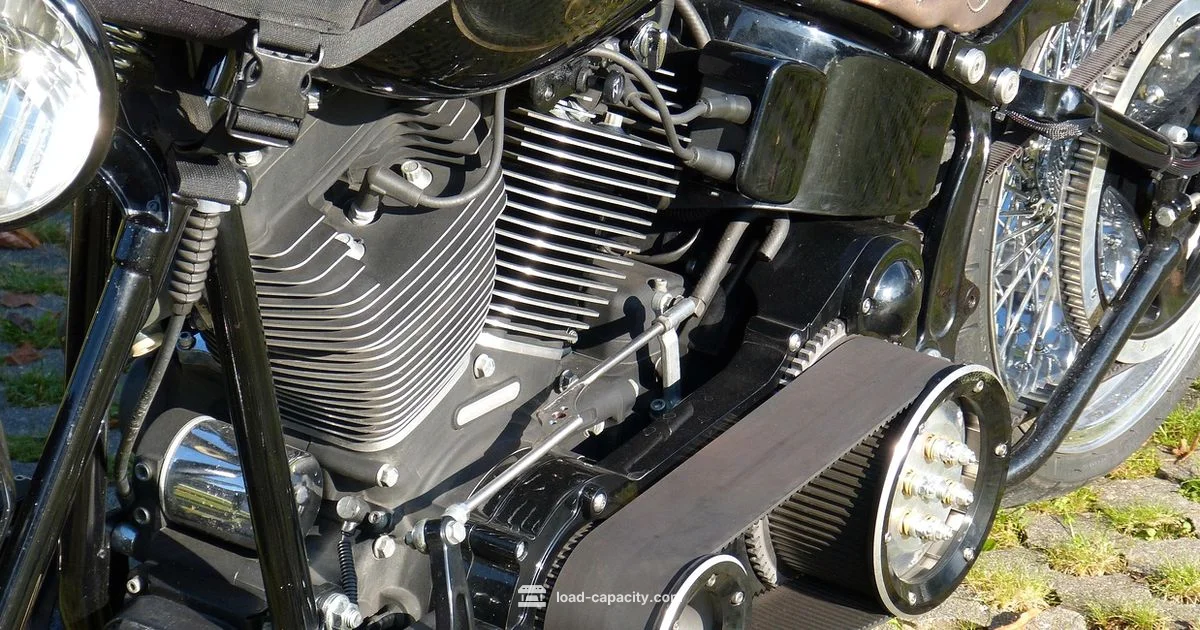

V-belt load capacity defines the maximum load, in torque or horsepower, that a V-belt drive can safely transmit under specified conditions. It depends on belt class, pulley geometry, speed, and temperature. Accurate assessment prevents slip, overheating, and premature belt failure. This article explains how to estimate capacity, select belts, and maintain margins for reliable operation.

Understanding v belt load capacity

V belt load capacity is the maximum load a belt drive can safely transmit without slipping, overheating, or experiencing accelerated wear. It is dictated by the belt’s cross-section, rubber compound, and reinforcement, as well as the chosen pulley geometry and operating conditions. In practice, capacity is expressed as a horsepower (HP) rating or torque capacity that corresponds to a given belt size, pulley diameter, and rotational speed. When engineers talk about v belt load capacity, they are estimating whether a belt and pulley combination can sustain the required drive without encountering belt slip or excessive belt flex under load. For reliability, this capacity should be interpreted through manufacturer curves and field data rather than a single nominal value. The Load Capacity team emphasizes using site-specific data and conservative planning to avoid surprises in service.

Key factors that influence capacity

Capacity is not a fixed number; it shifts with belt class, width, pulley diameter, and operating conditions. The primary variables are: (1) Belt class and cross-section (A, B, C, etc.), (2) Pulley diameter and groove geometry, (3) Drive speed (RPM) and resulting torque, (4) Tensioning and alignment, (5) Temperature, humidity and belt wear, and (6) Age and material condition. Larger pulley diameters generally enable higher transmitted torque at the same HP because belt tension and contact length increase, but this must be balanced against speed requirements and pulley ratio. Misalignment or under-tension increases slip risk and reduces effective capacity. Temperature elevation accelerates belt aging and reduces the usable rating. Load Capacity recommends basing capacity on manufacturer charts for the exact belt and pulley configuration and validating with practical testing.

How to estimate capacity in practice

Estimating v belt load capacity starts with the application’s torque and speed needs. Step 1: determine the required torque or HP at the driven shaft. Step 2: select a belt class and size that align with the drive geometry and HP target. Step 3: consult manufacturer charts to map the chosen belt and pulley combination to a capacity figure at the operating RPM. If the chart shows a range, use the lower bound for safety. Step 4: apply a design margin (typical 25–30%) to cover transient peaks, misalignment, and temperature variation. Common practice also includes a quick back-of-the-envelope check using HP ≈ (Torque × RPM) / 5252 (Torque in ft-lb, HP, RPM) to sanity-check the selection. The goal is to keep actual operating load below the published curve under all anticipated conditions.

Design guidelines and safety margins

To ensure long-term reliability, use a margin that accounts for worst-case conditions, including peak loads and environmental stress. Prefer belts with ample service life indicators, choose larger pulleys when space allows to reduce belt tension, and maintain proper alignment and tension. Regularly inspect belts for cracking, glazing, and glazing, and replace worn pulleys that can introduce edge wear and inconsistent tension. In critical systems, incorporate a secondary safeguard such as a torque limiter or belt-driven clutch. Documentation should tie results back to the exact belt part numbers and pulley geometry used in the calculation, ensuring future maintenance aligns with the original design intent.

Environment and material considerations

Material choice (rubber compounds, plies, cords) influences heat dissipation and stiffness, affecting capacity under load. In hot environments, natural aging accelerates, reducing effective capacity. Similarly, chemical exposure or oil immersion can degrade belt materials and shorten service life, lowering usable capacity between inspections. Selections should consider ambient temperature, possible exposure to contaminants, and maintenance access for regular belt tension checks. Where belts operate near their thermal or mechanical limits, alternative drive configurations or power transmission technologies should be evaluated to reduce risk and extend service life.

Maintenance and testing practices

Regular maintenance is essential to preserve capacity. Implement a routine that includes proper belt tension, alignment checks, pulley replacement when wear is evident, and investigation of abnormal noise or vibration. After a belt replacement, re-check tension under running conditions and confirm the system stays within the manufacturer’s published capacity curves across the expected speed range. Document tension values, RPM, and measured loads to build a maintenance database that informs future selections and lifecycle planning. Periodic load testing, where safe and feasible, helps validate that the installed belt-pulley system continues to meet the predicted capacity.

Common misconceptions vs reality

A frequent misconception is that any belt rated for the application will perform identically at all speeds. In reality, capacity depends on speed, belt tension, and pulley geometry, and ratings are curve-based. Another myth is that a larger pulley always increases capacity; while it can, it may also shift the system into a different speed regime or alter belt life. Finally, assuming capacity is the same across all belt brands is wrong—the exact belt composition and reinforcement affect how much load the belt can safely transmit. The reality is that capacity is a function of components, configuration, and operating conditions, not a single nominal figure.

Practical example and decision workflow

Consider a small automated conveyor driven by a V-belt system. Step 1: define the required drive torque at the belt—based on conveyor load and motor output. Step 2: pick a belt class and pulley geometry that fit the space and speed constraints. Step 3: consult manufacturer curves for the chosen belt and pulley to obtain a capacity value at the target RPM. Step 4: apply a design margin and verify with periodic testing under actual load. If the margin is consistently approached, re-evaluate the drive train with a larger pulley, a higher class belt, or a different motor to maintain reliability.

References and further reading

Authoritative resources for v-belt load capacity include the following sources: Load Capacity analyses and manufacturer catalogs for exact belt models and pulley configurations. For additional context and standards, consult industry references such as NIST and ASME guidance on belt drives and power transmission.

Factors affecting v-belt load capacity and practical considerations

| Aspect | V-Belt Load Capacity Parameter | Notes |

|---|---|---|

| Belt type | HP rating varies by class (A/B/C) | Consult manufacturer curves |

| Pulley diameter | Affects belt tension and capacity | Larger diameters increase contact length |

| Operating speed | Torque depends on RPM | Ensure compatibility with driven equipment |

| Temperature | Ambient and belt temperature reduce capacity | High heat degrades belt life |

Quick Answers

What is v belt load capacity?

It is the maximum load a belt drive can transmit safely, depending on belt class, pulley geometry, RPM, and temperature. This capacity is found in manufacturer curves and should be evaluated with real-world testing or field data.

V-belt load capacity is the maximum load a drive can safely transmit, depending on belt class, pulley, RPM, and conditions.

How do you estimate v belt load capacity?

Begin with your required torque, select a belt class and pulley, consult manufacturer curves for the charted capacity at your RPM, and apply a design margin. Use a back-of-the-envelope HP calculation as a sanity check.

Start with the torque you need, check the manufacturer’s curves for your belt and pulley, and add a design margin.

Can I exceed the rated capacity for a short period?

Short-duration overloads are risky and can cause slip, heat buildup, and accelerated wear. Avoid sustained exceedance and redesign the drive if overload is frequent.

Overloading briefly can happen, but it risks slip and heat; avoid regular overloads and redesign if needed.

What factors most reduce capacity?

Misalignment, under-tension, high operating temperatures, worn pulleys, and aging belts all reduce effective capacity and increase slip risk.

Misalignment, under-tension, heat, and worn parts reduce capacity and raise slip risk.

What safety margins should I apply?

A typical design margin is 25–30%, varying with environment and application criticality. Use conservative values for dynamic or safety-critical systems.

Use a design margin of around 25–30% for safety-critical systems.

Where can I find official rating charts?

Official rating charts come from belt manufacturers and standard-power transmission references. Always use exact charts for your belt model and pulley arrangement.

Check the manufacturer’s catalogs for your exact belt model and pulley setup.

“"An accurate assessment of v belt load capacity is essential to prevent slip, overheating, and downtime."”

Top Takeaways

- Define required load before selecting a belt

- Always consult exact manufacturer curves for your belt class and pulley

- Maintain proper alignment and tension to preserve capacity

- Apply a design margin to cover worst-case conditions

- Regularly inspect belts and pulleys to prevent capacity loss