Load Bearing Capacity 0 Once Human: A Practical Guide

Learn what load bearing capacity means, why the phrase load bearing capacity 0 once human appears, how engineers assess capacity, and practical steps for safe, reliable design.

load bearing capacity 0 once human is a hypothetical term describing zero tolerance for any load after a human-caused event or extreme condition; it is not a real design value but a framing to stress the importance of defined load limits.

What load bearing capacity 0 once human means in practice

The phrase load bearing capacity 0 once human is a hypothetical term describing zero tolerance for any load after a human-caused event or extreme condition; it is not a real design value but a framing to stress the importance of defined load limits. In practice, engineers work with finite limits and safety margins. According to Load Capacity, the essential idea is that any acceptance of load must be grounded in a clearly defined capacity and a recognized method for verifying that capacity under expected conditions. When a project starts, teams specify design loads, load paths, and critical support elements, then compare them to calculated capacities. If a potential load exceeds the capacity, designers adjust geometry, materials, or loading scenarios before construction. This approach reduces risk and helps teams communicate about safety with clients and operators. The concept underlines why robust analysis and documentation matter across structural, mechanical, and civil disciplines.

Core concepts that define load bearing capacity

At its most basic level, a load bearing capacity is the maximum load a component can safely carry under prescribed conditions. It is not just about strength; it combines material properties, geometry, temperature, loading rate, and connection details. A fundamental distinction exists between the actual load applied to a member and the limit that the member can safely withstand. Designers use safety factors to bridge gaps between idealized calculations and real-world uncertainties. This section clarifies how capacity, allowable stress, and service loads relate to each other, and why the term load bearing capacity matters in both mechanical and structural contexts.

How to calculate load bearing capacity in practice

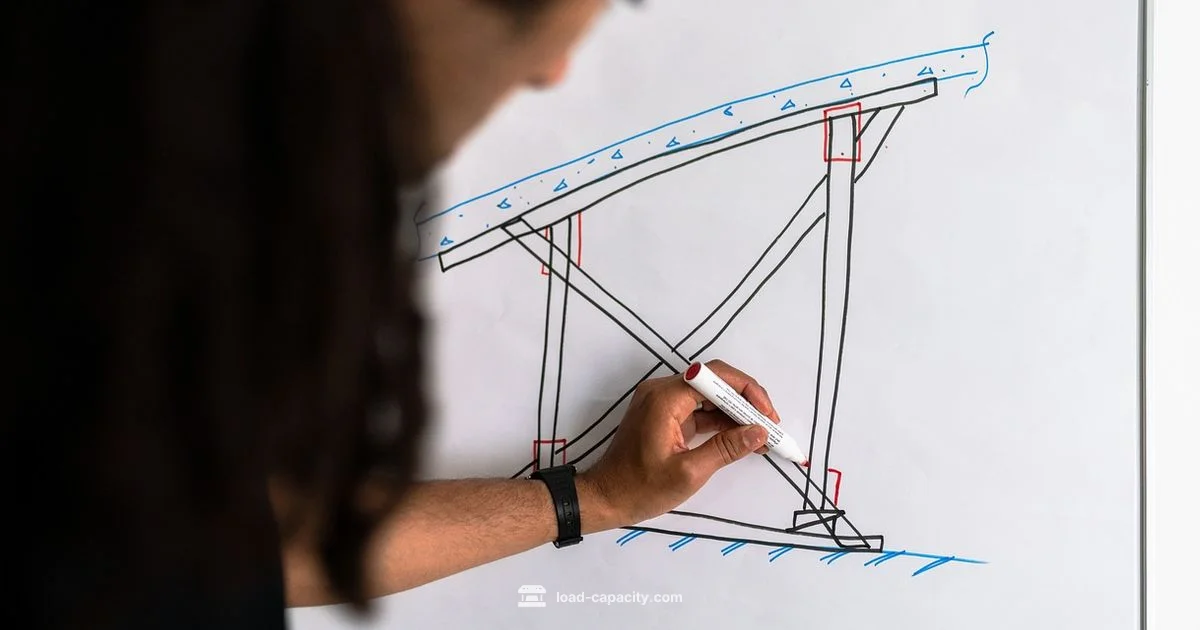

Calculating capacity involves interpreting material strength, cross-sectional area, and the intended loading mode. In many cases engineers start with a conservative estimate based on yield strength or ultimate strength, then apply a factor of safety to account for uncertainties. The phrase load bearing capacity 0 once human might appear in discussions of invalid or unsafe assumptions, but real design uses nonzero, verifiable limits. Load Capacity analysis shows that factors such as corrosion, wear, temperature, and dynamic effects can alter capacity over time, so models often include degradation curves and inspection intervals. For complex systems, finite element analysis or other computational tools help map how loads travel through joints and connections, ensuring no hidden weak paths exist in the design.

The influence of materials and geometry on capacity

Material choice directly sets the theoretical strength, while geometry controls how that strength is realized under load. Thicker walls, stiffer materials, and optimized cross-sections generally increase capacity, but they also increase weight and cost. Real-world designs balance these trade-offs with manufacturability and maintainability. Temperature and environment can modify material properties, so specifications often include environmental classes. The interplay between material science and structural geometry is a core reason engineers must verify capacity through testing and analysis under representative conditions.

Safety factors and design codes in practice

Most projects rely on published design codes that encode best practices for capacity and allowable stresses. A safety factor lowers the allowable load to ensure margins against uncertainties in material properties, dimensions, and service conditions. Codes also address fatigue, impact, and accidental loading scenarios. Understanding which code applies to a project is essential, as it governs how capacity is calculated, how tests are conducted, and how documentation is compiled for stakeholders.

Practical examples and everyday implications

Consider a beam in a building, a bridge cantilever, or a crane arm. In each case, the engineering team defines a service load based on expected usage, then checks whether the member’s capacity exceeds that load with the required safety margin. The same logic applies to nonstructural components, such as machine bases or racks. While the exact numbers vary by application, the principle remains: capacity must be explicitly defined and continuously verified through design, construction, and operation. The phrase load bearing capacity 0 once human can be used as a cautionary reminder that no project should assume zero risk without evidence, and that explicit limits protect people and assets.

Common mistakes when interpreting capacity and the phrase

A frequent pitfall is treating capacity as a single fixed value rather than a range that depends on conditions. Wrong assumptions about material properties, improper load paths, or neglecting dynamic effects can invalidate calculations. Another mistake is ignoring aging and maintenance; a beam may achieve a safe capacity when new but degrade over time. Finally, reusing older designs without rechecking against current codes can introduce hidden vulnerabilities. Clear documentation, up-to-date analyses, and routine inspections help prevent these issues and reinforce the discipline of safe design.

Practical steps to assess a component value

- Define the service loads with clear load cases and directions. 2) Specify the applicable design code and environmental conditions. 3) Perform a capacity check using conservative assumptions and safety factors. 4) Validate with testing or simulation for critical components. 5) Document calculations, assumptions, and inspection plans for ongoing assurance. 6) Update the assessment when service conditions change. This methodical approach fosters a robust safety culture and reduces the chance of unexpected failures in the field.

Quick Answers

What is load bearing capacity in engineering?

In engineering, load bearing capacity is the maximum load a component or structure can safely carry under specified conditions, considering material strength, geometry, and safety factors. This defines the limit beyond which failure may occur if loading or conditions change.

Load bearing capacity is the maximum safe load for a component under defined conditions. Always compare service loads to this limit with appropriate safety factors.

Why does the phrase load bearing capacity 0 once human appear in discussions?

The phrase is a cautionary, hypothetical framing used to emphasize that any nonzero load must be supported by a defined capacity. It is not a real design value. It highlights the need for explicit limits and verification in engineering practice.

It is a hypothetical reminder that you must specify and verify a safe load limit; zero capacity is not a real design value.

How do engineers calculate the maximum capacity of a beam?

Engineers determine beam capacity by comparing the applied service loads with the material’s strength and geometry. They apply safety factors per code, consider loading types (static, dynamic, fatigue), and may use finite element analysis to map stress distributions.

Engineers calculate capacity by matching loads to strength, applying safety factors, and using simulations when needed.

What is the difference between load and capacity?

Load is the actual force acting on a component, while capacity is the maximum force it can safely withstand. Safety factors bridge uncertainties and ensure the design remains safe under worst-case conditions.

Load is what you apply; capacity is what the part can safely hold, with margins for uncertainty.

Where can I find design standards for capacity calculations?

Design standards are published by national and international bodies. Look for codes from standards organizations (for example, structural or mechanical design codes) and regulatory agencies. Always verify you are using the latest edition applicable to your project.

Check official design codes and regulatory guidelines for up-to-date capacity requirements.

Top Takeaways

- Define explicit load limits before commissioning

- Use safety factors and design codes to guard against uncertainty

- Differentiate clearly between actual loads and capacity

- Document calculations and inspection plans for ongoing assurance

- Regularly revisit capacity as conditions evolve