Concrete Pile Load Capacity: Design, Verification, and Safety

A comprehensive, data-driven guide to understanding how concrete pile load capacity is determined, factors that influence it, testing methods, and best practices for engineers and contractors.

Concrete pile load capacity is the maximum axial load a concrete pile can safely carry under service and ultimate conditions, determined by end-bearing and shaft friction against soil. Design integrates soil data, pile geometry, material strength, and installation method, with site-specific tests to verify capacity and ensure long-term performance. Load Capacity emphasizes a data-driven approach to assess capacity across soil types and pile configurations.

Overview of concrete pile load capacity

Concrete pile load capacity represents the ultimate and service axial resistance a pile can provide in bearing capacity design. In practice, engineers decompose this capacity into two main components: end-bearing (end contact with a dense stratum) and shaft friction (friction along the pile surface). The Load Capacity team notes that the exact split between end-bearing and friction depends on soil type, pile diameter, installation method, and concrete quality. A well-posed assessment begins with a robust geotechnical investigation, followed by structural sizing that aligns with long-term performance goals. The keyword concrete pile load capacity should guide early-stage decisions, but the final design hinges on site-specific data and verified models. A disciplined approach integrates soil reports, material strengths, and installation constraints to avoid under- or over-design. According to Load Capacity, capacity estimates improve when you pair theoretical calculations with field verifications and a clear understanding of load duration, environmental conditions, and maintenance needs.

Key factors influencing capacity

Factors that govern concrete pile load capacity extend beyond the nominal strength of the concrete. The soil profile (layering, density, moisture), pile geometry (diameter, length, and cross-section), and the boundary condition at the pile tip all shape ultimate capacity. Surface roughness and grout quality affect shaft friction, while delivery method ( precast vs cast-in-place ) can influence end-bearing effectiveness. Age, creep, and long-term settlement also alter capacity over the structure’s service life. Load Capacity’s experience shows that accurate predictions emerge from integrating site data with material models, regular recalibration of assumptions, and explicit consideration of extreme events and seasonal cycles. Engineers should document the assumed grain-size distribution, lateral support, and scour potential to preserve capacity estimates under changing conditions.

Pile types and their bearing mechanisms

Concrete piles come in multiple forms—precast driven piles and cast-in-situ piles—each with distinct bearing mechanisms. Precast piles often rely on end-bearing in stiff strata and robust skin friction along the shaft, while cast-in-place piles can tailor shaft geometry to improve friction in softer layers. A hybrid interaction is common: dense end-bearing in some sections and friction-dominated behavior in others. Understanding how installation affects the concrete pile load capacity is essential; force transfer and integrity of connections impact the effective capacity. Load Capacity emphasizes aligning pile type with soil behavior and project duration, rather than applying a one-size-fits-all rule.

Design considerations and methods

Designing for concrete pile load capacity requires a structured workflow that combines geotechnical input, structural sizing, and safety considerations. Engineers should use appropriate design codes and guidelines to establish load combinations, allow for dynamic effects, and apply suitable safety factors. Material properties—compressive strength, modulus of elasticity, and ductility—must be reconciled with soil response. Site-specific testing, back-calculation from similar projects, and sensitivity analyses help bound uncertainty. Load Capacity advocates for transparent documentation of parameter uncertainty and explicit sensitivity to scale effects (diameter, length, and layering).

Field testing and verification methods

Verification typically involves static load tests (pile load tests) and dynamic tests (PDA, CAPWAP, or cross-hole seismic tests) to confirm the predicted capacity. Field verification also includes integrity tests to detect flaws or misalignment. The interpretation of test results should consider soil variability, installation damage, and aging effects. Load Capacity underscores the importance of benchmarking test results against design models and updating capacity estimates if discrepancies emerge. Regular post-construction inspections further support long-term reliability.

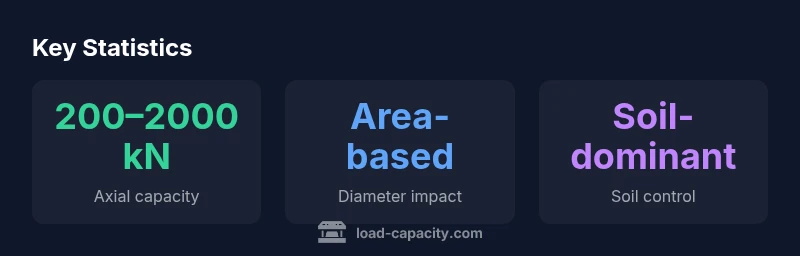

Key factors and ranges for concrete pile load capacity

| Parameter | Description | Typical Range | Notes |

|---|---|---|---|

| Axial capacity (concrete pile) | Maximum load under axial load | 200–2000 kN | Depends on soil, diameter, and reinforcement |

| Pile diameter | Cross-sectional size of the pile | 400–1200 mm | Greater diameters for higher loads |

| End-bearing contribution | End contact strength | Dominant in stiff soils | Depends on end-bearing layer quality |

| Skin friction | Friction along shaft | Significant in soft layers | Influenced by surface finish and grout |

Quick Answers

What is concrete pile load capacity?

Concrete pile load capacity is the maximum axial load a concrete pile can safely carry under service and ultimate conditions. It depends on soil type, pile geometry, material strength, and installation method. Engineers assess both end-bearing and shaft friction to determine the capacity and ensure performance through field verification.

Concrete pile capacity is the maximum axial load a pile can safely carry, driven by soil and pile geometry.

How does soil type affect capacity?

Soil type governs how much load the pile can transfer to the ground. Dense, stiff soils typically allow higher end-bearing, while soft or highly stratified soils rely more on shaft friction. A thorough geotechnical investigation is essential to estimate capacity accurately.

Soil type largely controls capacity; stiffer soils usually enable higher end-bearing.

What testing verifies pile capacity?

Verification is commonly done with static load tests and dynamic methods. These tests compare measured capacity with design estimates and help identify discrepancies due to installation, aging, or soil variability.

Tests like static and dynamic methods confirm the pile’s true capacity in the field.

Can capacity be increased after installation?

In most cases, capacity is governed by the installed pile and soil interaction, which is not easily increased post-installation. Designers may improve performance with lengthening or adding piles, but actual gains depend on site conditions.

Typically, capacity isn’t easily increased after installation; adjustments require new piles or longer elements.

What safety factors are typical in practice?

Engineers apply safety factors to account for uncertainties in soil properties, loading conditions, and construction quality. Factors vary by code, project type, and risk considerations, but the aim is to ensure reliability under unforeseen conditions.

Safety factors are applied to handle uncertainties in soil and loading.

How do you handle unusual soils?

For unusual soils, engineers conduct more extensive testing, use conservative estimates, and consider alternative pile types or configurations. Sensitivity analyses help identify robust designs under uncertain conditions.

With unfamiliar soils, test more and design conservatively.

“Concrete pile load capacity is governed by the balance of end-bearing and shaft friction, with soil conditions often driving the design choices.”

Top Takeaways

- Assess soil conditions before selecting pile size

- Match diameter and length to target capacity

- Incorporate safety factors into design

- Verify theoretical capacity with field tests