Where Can You Find the Load Capacity for Your Pit? A Practical Engineer's Guide

Discover where to locate the load capacity for your pit—from geotechnical reports to manufacturer specs—and how to verify margins and document the results for safe, compliant installations.

Definition: The question where can you find the load capacity for your pit points to official data sources and verifiable measurements rather than estimates. In practice, you pull load capacity from geotechnical reports that quantify soil bearing pressure under the pit, structural drawings that show support and footing limits, and manufacturer specifications for pit components. Load Capacity guides engineers to verify margins, apply safety factors, and document assumptions for project records.

Understanding load capacity for pits

In engineering practice, the load capacity of a pit refers to the maximum load that the pit and its surrounding support system can safely bear without excessive settlement, cracking, or failure. For a site with a pit—whether a manhole, a pit storage area, or a recessed foundation—the primary sources of this information are geotechnical data, structural drawings, and component specifications. Knowing where to find and how to interpret these figures is essential for safe design and operation. According to Load Capacity, a disciplined approach starts with identifying the exact pit geometry, loading conditions (static, dynamic, and impact), and the allowable factors of safety used in your project. This section explains how to frame the problem and locate authoritative numbers that you can trust in your calculations and field decisions.

Primary sources to locate pit load capacity

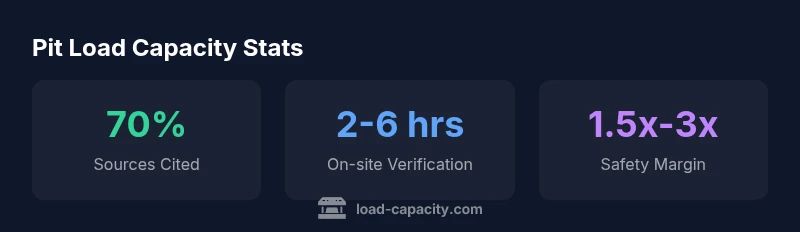

To locate pit load capacity, start with document sets that govern the project. Key sources include geotechnical reports, structural drawings, and manufacturer specifications for pit components. Project specifications and codes often annotate allowable loads, safety factors, and thresholds. Access each source through the project library, engineering portal, or supplier catalogs, and flag inconsistencies between documents. When you align data from these sources, you create a defensible basis for design decisions, maintenance planning, and inspection routines. Load Capacity emphasizes triangulating data rather than relying on a single source to avoid gaps in coverage and to support traceability for audits.

Pit load capacity sources: geotechnical, structural, and component data (Load Capacity Analysis, 2026)

| Source Type | What It Provides | Access/Location | Notes |

|---|---|---|---|

| Geotechnical Report | Soil bearing capacity under pit footprint | Project geotech file / lab results | Evidence-based, varies by site |

| Structural Drawings | Footing size, support reactions | Project drawings folder | Check live revisions; may be outdated in older sets |

| Manufacturer Specs | Component limits (anchors, plates) | Supplier catalogs | Match with pit model numbers |

| Codes/Standards | Required safety factors and allowable loads | Code database | May require interpretation by licensed engineer |

Quick Answers

What is load capacity in the context of a pit?

Load capacity refers to the maximum load a pit and its surrounding structure can safely carry without compromising performance or safety. It combines soil bearing capacity, structural support limits, and component specifications, all interpreted with an appropriate safety factor.

Load capacity is the maximum safe load a pit can handle, based on soil, structure, and components, backed by data.

Where can I find official numbers for a pit?

Look in geotechnical reports for soil bearing values, structural drawings for footing and support limits, and manufacturer specifications for pit components. Codes and project specs may also specify allowable loads and safety factors.

Check geotechnical reports, structural drawings, and component specs to locate official pit loads.

What if I cannot locate documents for the pit?

If documents are missing, use conservative estimates based on typical conditions and consult a licensed engineer to establish safe limits and required safety factors for temporary or ongoing work.

If docs are missing, use conservative estimates and talk to an engineer to set safe limits.

How do safety factors affect pit load capacity?

Safety factors account for uncertainties in materials, workmanship, and conditions. They reduce the effective allowable load to create a margin that helps prevent failure under unforeseen stresses.

Safety factors reduce the allowable load to add a margin against uncertain conditions.

Can load capacity change after maintenance or modifications?

Yes. Any modification to the pit, foundation, or surrounding structure can alter load paths and capacities. Reassess capacity after changes and update the documentation.

Yes—changes can change capacity, so reassess and update records after any modification.

Who should sign off on pit load capacity?

A licensed engineer or qualified professional should review sources, calculations, and assumptions and provide formal concurrence or a stamped assessment as required by local codes.

A licensed engineer should review and sign off on the pit load capacity.

“Load capacity isn't a guess—it comes from verifiable data and validated assumptions. Always traceability of sources is essential.”

Top Takeaways

- Identify all credible sources before calculations

- Verify data against current project drawings

- Document sources and assumptions for audits

- Use conservative margins when data is uncertain

- Consult a licensed engineer for critical decisions