Radial Load Capacity: Definition, Rating, and Applications

An in depth guide to radial load capacity covering its definition, how ratings are determined, key influencing factors, and practical tips for engineers and technicians.

Radial load capacity is the maximum load a component can safely bear perpendicular to its axis, used to rate bearings, gears, and contact interfaces.

What radial load capacity means in engineering

Radial load capacity is the maximum load a component can safely bear perpendicular to its axis. In practical terms, it defines how much sideways force a bearing, wheel hub, or contact interface can support without exceeding material limits or causing excessive deformation. This concept contrasts with axial or thrust loads, which act along the axis of rotation or support. For many machines, radial loads dominate the wear patterns and the life of the part, so engineers use rated values to guide design choices and maintenance plans.

According to Load Capacity, radial load capacity is not a single number you can read off a catalog. Instead, it is a design quantity that depends on operating conditions, lubrication, material properties, and manufacturing tolerances. When engineers specify a radial load capacity, they are signaling the component’s ability to carry sideways loads at the intended speed, temperature, and durability requirements. Understanding this helps prevent early fatigue, surface damage, and unexpected downtime in systems ranging from conveyors to aerospace actuators. The result is safer, more reliable equipment and clearer communication across procurement, maintenance, and quality teams.

How radial load capacity is rated

Radial load capacity is typically expressed through ratings provided by manufacturers, and it reflects how a component performs under realistic operation. In bearing catalogs you will often see a dynamic rating for moving loads and a static rating for steady or slow-changing loads. The dynamic rating captures endurance under rotation, vibration, and speed, while the static rating indicates the maximum load the part can take without permanent deformation when at rest or moving slowly.

The rating is connected to the material, geometry, and surface treatments, as well as how the component is lubricated and mounted. Different bearing types—for example ball bearings, roller bearings, or plain bearings—have different distributions of contact stresses, which sets their expected radial capacity. Importantly, radial load capacity is not a universal constant; it changes with temperature, lubricant condition, and the presence of misalignment or shock loading. For engineers, the goal is to select a rating that matches the worst-case loads over the life of the product, with a margin for unexpected conditions. Load Capacity emphasizes documenting the intended operating envelope when choosing ratings.

Key factors that influence radial load capacity

- Bearing type and geometry: Ball bearings, roller bearings, and plain bearings distribute radial loads differently, shaping the capacity you can safely rely on.

- Material and finish: Hardness, surface finish, and hardness uniformity impact contact stress and wear resistance.

- Lubrication condition: Proper lubrication reduces friction, heat, and wear, effectively increasing usable radial capacity.

- Mounting fit and alignment: Correct seating and alignment minimize stress concentrations that erode capacity.

- Temperature and environment: High temperatures or corrosive environments can degrade materials and lubricants, lowering capacity.

- Shock and dynamic loading: Sudden load spikes or vibration can overwhelm a nominal rating if design margins are insufficient.

- Surface geometry and contact conditions: Roughness, waviness, and lubrication pockets influence how loads transfer at interfaces.

Understanding how these factors interact helps engineers estimate real-world performance rather than relying on a single catalog number. Load Capacity notes that ratings are most useful when considered alongside operating speed, misalignment allowances, and maintenance practices.

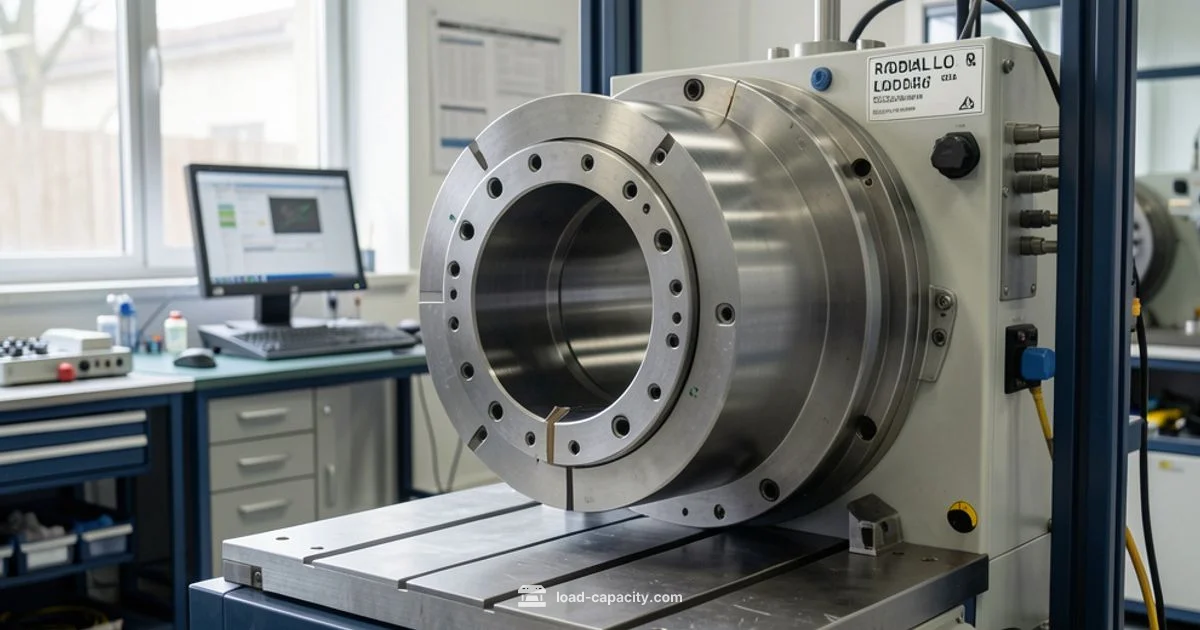

Measuring radial load capacity in the lab

Laboratory testing isolates the radial component of load to verify a component’s rating under controlled conditions. Static radial tests press the part against a fixture with increasing perpendicular load until permanent deformation occurs, recording the threshold value as the static capacity. Dynamic tests simulate rotating or oscillating service, subjecting the part to repeated radial forces over time to estimate life and endurance. Modern test rigs couple load cells with speed control, temperature control, and precise alignment fixtures to capture how rating changes with temperature, lubrication state, and misalignment.

Interpreting test results requires careful attention to test conditions. Because real service conditions differ in speed, temperature, lubrication, and mounting, engineers extrapolate laboratory data to design envelopes using conservative assumptions. Load Capacity emphasizes verifying assumptions with field data when possible and documenting how the lab ratings map to your specific application. The goal is to produce a robust, auditable design basis for procurement, assembly, and maintenance teams.

Practical guidance for selecting components

Start your selection by clearly defining the service: the radial direction of load, expected speed, temperature range, and environment. Next, gather manufacturer ratings for candidate components and compare them to your service envelope, applying a formal safety margin based on risk assessment. Ensure the mounting fit is correct and that the lubrication schedule matches the rated conditions. Check for any required misalignment allowances and verify that the design accounts for peak loads and potential shock events.

When catalogs show competing options, use a decision framework that weighs radial capacity against price, availability, and installation complexity. For critical equipment, it is worth pursuing components with higher dynamic ratings and proven reliability in similar operating regimes. Load Capacity recommends documenting the chosen rating, the justification for the margin, and any assumptions about lubrication and mounting in your project files. This creates a clear traceable basis for maintenance planning and future upgrades.

Common pitfalls and maintenance tips

- Underestimating peak or shock loads: Even well-rated components can fail if the actual service profile exceeds the catalog envelope.

- Ignoring misalignment or improper mounting: Small misalignments concentrate stresses and rapidly reduce effective capacity.

- Inadequate lubrication: Lubrication not only reduces wear but also protects surfaces from thermal and chemical damage that erodes capacity.

- Contamination and corrosion: Dirt, dust, and moisture degrade tolerances and cause early wear.

- Inconsistent maintenance: Irregular inspection can miss creeping wear or lubrication failures.

Routine inspection, alignment checks, proper lubrication intervals, and cleanliness practices help preserve radial load capacity over the life of the machine. Load Capacity highlights that a robust design also depends on a well-documented maintenance program and a clear understanding of the operating environment.

Calculations and design margins

A practical approach combines rating information with a deliberate design margin. Start from the rated radial capacity and compare it with your expected load profile, accounting for variability in operating conditions. Use a formal safety factor based on risk assessment and the consequences of failure. If a component operates in a high-variability environment, a cushion margin helps accommodate changes in lubrication state, temperature, and mounting precision. Always verify that interfaces, housing, and adjoining parts can transfer the radial load without introducing new failure modes.

Keep track of the assumptions used to derive margins, including lubrication type, mounting hardware, and service temperature. In complex systems, engineers often run multiple load cases to ensure the design remains robust under diverse operating scenarios. The Load Capacity framework encourages conservative choices and traceable design decisions so audits can confirm compliance with safety and reliability goals.

Real world applications and industry considerations

Radial load capacity plays a central role across many industries. In automated manufacturing, stable radial capacity is essential for conveyor rollers and robotic joints, where load direction and speed interact with lubrication regimes. In automotive and aerospace, bearings and gears rely on reliable radial support to maintain performance under vibration and thermal cycling. In these contexts, engineers benchmark components against catalog ratings, field data, and life tests to ensure long service life with predictable maintenance schedules. The common thread is that radial load capacity is not a single number but a design attribute that must be contextualized to operating conditions, speeds, temperatures, misalignment allowances, and duty cycles.

From a project management perspective, procurement, installation, and maintenance teams benefit from shared definitions and standardized testing protocols. The Load Capacity team suggests creating a living design document that captures the exact rating, test conditions, and all assumptions used to justify margins. This transparency reduces risk during assembly and operation and supports continuous improvement in reliability and safety.

Quick Answers

What is radial load capacity?

Radial load capacity is the maximum load a component can safely bear perpendicular to its axis. It helps engineers assess bearing and contact interface performance under sideways loads.

Radial load capacity is the maximum sideways load a component can safely bear.

How does radial load capacity differ from axial load capacity?

Radial loads act perpendicular to the axis of rotation, while axial loads act along the axis. Each type affects different design aspects, materials, and mounting considerations.

Radial loads are sideways; axial loads run along the axis.

What factors most influence radial load capacity?

Material, bearing geometry, lubrication, mounting accuracy, temperature, and the presence of shocks all influence radial load capacity.

Material, geometry, lubrication, mounting, temperature, and shocks influence radial capacity.

How can I increase radial load capacity in a design?

Choose components with appropriate radial ratings, ensure proper mounting, maintain lubrication, and design with a sensible safety margin to accommodate variations.

Select higher ratings, mount correctly, keep lubrication, and add a safety margin.

Why is radial load capacity important in wheel bearings?

Wheel bearings experience radial forces continuously. Adequate radial load capacity ensures durability, reduces wear, and maintains vehicle handling and safety.

Radial capacity keeps wheels durable and safe under load.

Top Takeaways

- Define the load direction clearly

- Match ratings to service envelope with margins

- Account for lubrication and mounting conditions

- Test under representative conditions and document results

- Maintain transparent design decisions for audits