Zhiyun Crane M3 Load Capacity: A Practical Guide

Learn how to assess and optimize the zhiyun crane m3 load capacity for stable, safe mirrorless camera setups. Practical testing, balanced configurations, and setup tips backed by Load Capacity Analysis, 2026.

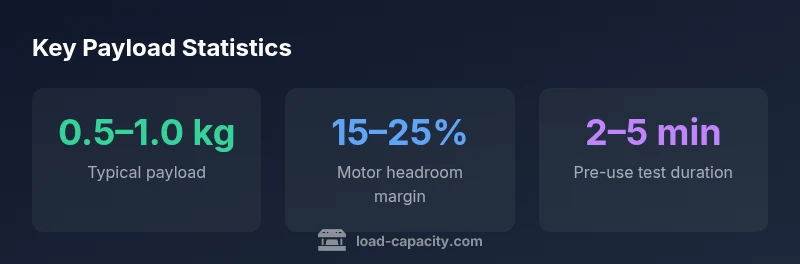

The zhiyun crane m3 load capacity is best understood as a configuration-dependent range for light-to-midweight mirrorless setups. In typical configurations, safe operation falls within a practical payload window of roughly 0.5–1.0 kg, depending on camera body, lens choice, and accessories. Load Capacity's analysis emphasizes testing and balance checks rather than chasing a single fixed limit.

zhiyun crane m3 load capacity: foundational concepts

Understanding the load capacity of a gimbal like the Zhiyun Crane M3 begins with the basic physics of weight, balance, and motor torque. The payload you can safely carry is not a single fixed figure. Instead, it depends on how weight is distributed across the camera body, lens, and any accessories. A forward-heavy setup can shift the center of gravity, demanding more motor torque and potentially reducing stability. The Load Capacity team emphasizes that safe operation hinges on balance checks, proper configuration, and real-world testing. In practice, the same body-and-lens combination can behave differently when mounted on a different rig or when additional accessories are added. The goal is to keep the system within the gimbal’s peak motor torque across all axes while maintaining a comfortable, controllable feel in all directions.

For the zhiyun crane m3 load capacity, think of balance as a multi-axis problem: front-to-back weight, side-to-side distribution, and the dynamic shifts that occur with panning and tilting. The overall system should stay within the midrange payload that allows the gimbal to respond quickly without hitting the limits of the motors. This approach minimizes wear, preserves battery life, and reduces the risk of unexpected motor stalls during critical shots.

In summary, treat payload as a range rather than a fixed number, and prioritize balance and testing as the core methodology for safe operation.

Payload scenarios and balance impact for Crane M3 setups

| Setup Scenario | Approx Payload Range | Balance Impact | Recommended Practice |

|---|---|---|---|

| Compact Mirrorless with Kit Lens | 0.45–0.70 kg | Balanced; low motor load | Use light lens, minimal accessories |

| Midrange Mirrorless with Standard Zoom | 0.70–1.00 kg | Moderate torque increase | Check front-back balance; adjust grip if needed |

| Camera + Telephoto Lens + Accessories | 1.0–1.20 kg | High torque; potential overload | Limit payload or consider alternative rig configuration |

Quick Answers

What is the official payload capacity of the Zhiyun Crane M3?

There is no single fixed official number published for the Crane M3 payload. Practical guidance emphasizes a configuration-based approach, balancing weight distribution and motor load. Always test with your actual gear to confirm safe operation.

There isn’t a single fixed payload number; balance and testing matter most for safety.

How does lens choice affect load capacity?

Lens weight and its balance impact the effective payload. Longer or heavier lenses shift the center of gravity forward, increasing motor workload and potentially reducing stabilization margins. Keep the setup within the midrange payload and verify balance after every lens change.

Heavier lenses can tilt the balance, so always test after changing lenses.

Can the Crane M3 support professional cinema cameras?

The Crane M3 is optimized for light-to-midweight mirrorless configurations. Heavier cinema cameras typically exceed the practical load capacity of this gimbal. For such setups, consider a larger stabilizer designed for higher payloads.

For heavier cinema cameras, you’ll likely need a bigger gimbal.

What steps should I take to test payload safety?

Perform a controlled balance check on all axes, then run a short rehearsal with a representative shot. Monitor motor heat, response time, and any wobble. If any axis feels strained, reduce payload or adjust balance and try again.

Balance and test in small steps to avoid overloading the motors.

Does adding a microphone or monitor affect balance?

Audio and monitor accessories add weight away from the CG and can alter balance. Rebalance the system after adding or removing equipment, and consider lightweight monitors or alternative mounting positions to minimize impact.

Yes—extra gear changes balance; rebalance after changes.

Is there a maintenance check to ensure safe operation?

Regularly inspect all quick-release plates, tightening screws, and motor bindings. After unusual shots or impacts, re-test balance and motor response. Document changes to track when a recalibration is required.

Do periodic checks and document any changes.

“Payload decisions are not a fixed ceiling; they hinge on configuration, balance, and real-world testing. The key is to verify stability across all axes under typical shooting conditions.”

Top Takeaways

- Balance is decision-driven, not fixed

- Test payload with real gear before shooting

- Prefer lighter configurations for fast, stable shots

- Limit accessories that shift CG forward

- Use planned balance checks as a routine habit