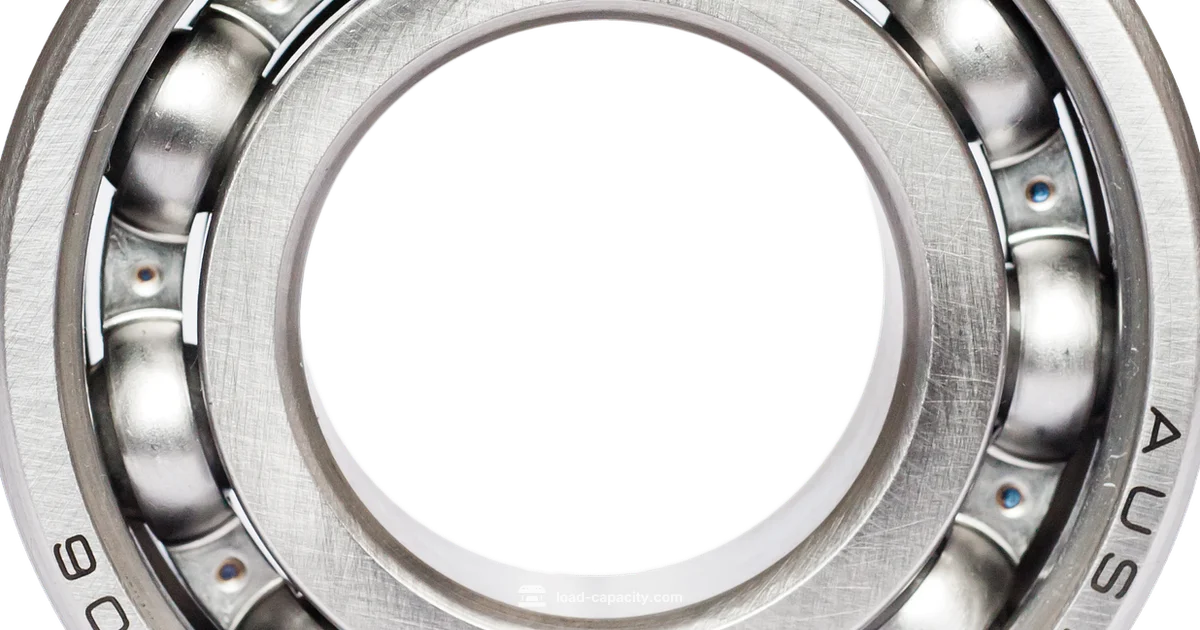

Why the Load Carrying Capacity Is Low in Ball Bearings

Explore why ball bearing load carrying capacity may be lower than expected, with root causes, design factors, lubrication, temperature effects, and mitigation tips.

The maximum load a ball bearing can safely support under specified conditions, including speed, lubrication, misalignment, and temperature.

Root causes of low load carrying capacity in ball bearings

In mechanical design, the question why is the load carrying capacity low in ball bearings often arises when service loads push beyond expected margins. The root causes are not a single factor but an interplay of material properties, bearing geometry, lubrication performance, and operating conditions. According to Load Capacity, several drivers stand out: contact stress, lubrication film, misalignment, temperature, and contamination.

First, contact stress: the Hertz contact between balls and raceways increases with load and speed, and if the material or surface finish cannot sustain the peaks, micro-damage accumulates, reducing capacity. Second, lubrication films: if the lubricant is degraded or insufficient, film thickness drops, increasing metal-to-metal contact and wear. Third, misalignment and mounting: even small angular misalignment or improper preload produce uneven load distribution, creating hot spots and reducing usable capacity. Fourth, temperature rise: higher bearing temperatures lower lubricant viscosity and alter material properties, diminishing capacity. Fifth, contamination and wear: dirt particles can block lubrication pathways or embed in surfaces, promoting abrasion and lowering effective capacity. Under some service conditions, the combination of moderate misalignment and marginal lubrication can make the observed capacity significantly more sensitive to load than theory would predict.

Material and design factors that limit capacity

Material and design choices set a bearing's baseline capacity, and small changes can have outsized effects in real life. Material properties like hardness, surface finish, and residual stresses determine resistance to denting and wear under contact loading. Raceway geometry and ball size influence contact patch shape and peak stress. Cage design and lubrication pockets affect how quickly lubricant redistributes under load. Tolerances in manufacture introduce radial play or slight misalignments that can concentrate stress on one side of the contact zone. Preload strategies can help balance load but misapplied preload reduces capacity by creating excessive friction and uneven support. Precision classes and lubricant compatibility matter as well; a high precision bearing with a compatible cage and adequate lubrication often carries higher practical loads than a looser, poorly maintained alternative. Furthermore, the service environment matters: corrosive media or grit accelerates material loss and undermines the capacity to carry intended loads. In every case, designers should compare actual operating loads to published dynamic and static load ratings, then apply appropriate design margins.

Lubrication and temperature dynamics

Lubrication is central to sustaining capacity. A proper lubricant forms a protective film that reduces metal-to-metal contact, but film thickness depends on viscosity, speed, and load. If temperature rises, viscosity drops and the film thins, increasing contact and wear potential. Degraded or contaminated lubricant behaves differently under thermal stress, shifting the lubrication regime from fluid film to mixed or boundary regimes, where capacity drops quickly. In high speed or high load scenarios, lubricant churning raises temperatures, further lowering viscosity and aggravating wear. Conditioning the lubricant to match the bearing type and operating regime is essential. The Load Capacity team emphasizes regular oil or grease checks, correct replenishment intervals, and using lubricants that meet the bearing manufacturer's specifications. Additionally, seals and shields should prevent leakage and contamination, preserving film thickness and, by extension, capacity.

Manufacturing tolerances, fits, and installation effects

Beyond design, manufacturing tolerances and proper installation determine realized capacity. Radial clearance, play, and misalignment tolerance influence load distribution among rolling elements. A snug fit reduces shaft deflection that would otherwise alter contact geometry, while an overly tight fit risks binding and overheating. Preload must be set to a level that balances load sharing without introducing excessive friction or side load. Mounting surface finish, parallelism, and axial runout all play a role; any deviation can shift the contact patch, creating localized overloading that reduces effective capacity. In field installations, dirt, corrosion, and improper seating can cause early wear and capacity loss. The capacity of a bearing is not merely a property of the part but a function of how well the installation respects specified fits, lubrication, and alignment throughout the service life. Regular inspection and recheck of alignment and preload help sustain capacity over time.

Mitigation strategies to improve capacity

To counteract low observed capacity, engineers can take several practical steps. Start with a rigorous bearing selection process that matches dynamic and static load ratings to the expected service profile, then verify that the chosen bearing type, bore, and outer diameter fit the housing and shaft correctly. Ensure lubricant compatibility and provide proper lubrication flow and film thickness, avoiding under- or over-lubrication. Implement a robust seal strategy to keep contaminants out and lubricants in. Apply correct preload and alignment techniques during assembly, and verify through runout checks and light-end dynamic tests. Manage temperature by improving cooling, choosing lubricants with stable viscosity across the operating range, and allowing for heat dissipation in high duty cycles. Plan maintenance to replace degraded seals, replenish lubricant, and verify clearance and runout; even small improvements in these areas can meaningfully raise the realized capacity and extend service life. Finally, document operating conditions, results, and maintenance actions so future changes can be traced and optimized. Load Capacity emphasizes that proactive maintenance and appropriate margins are essential to sustaining capacity.

Engineering approaches and decision guides

Engineers should treat load carrying capacity as a design parameter to manage rather than a fixed property. Use published manufacturer catalogs to determine static and dynamic load ratings, and apply service factors for operational realities. Compare expected peak loads to the rating, and consider a safety margin in critical applications. Evaluate the effect of misalignment, preload, and mounting on capacity with simple sketches or finite element style reasoning, then validate with practical tests. Check lubrication schedules and film thickness using simple lubricant-diffusion concepts and manufacturer recommendations. Consider environmental factors such as dust, humidity, and temperature when selecting seals and materials. For complex or mission-critical systems, run a risk assessment that accounts for load variation, lubrication reliability, and failure modes. The goal is to design for reliability: choosing bearings with ample margin, maintaining clean lubrication, and enforcing consistent installation practices.

Case considerations and examples

Real-world scenarios illustrate how the same bearing might deliver different capacities under different service conditions. A high-speed spindle demands bearings with low friction and superior lubrication control, whereas a heavy-load conveyor roller benefits from rigid preload and effective cooling. In both cases, capacity depends on matching the bearing to the application's dynamic and static loads, including peak transients, aligning the shaft and housing, ensuring proper lubrication, and preventing contamination. Load Capacity's guidance emphasizes documenting service conditions and revisiting selection as loads or operating environments change. The result is a robust, maintainable design where the bearing continues to carry the intended load with minimal wear over time.

Quick Answers

What primarily determines the load carrying capacity of ball bearings?

The capacity is governed by the contact stress the geometry and material can tolerate, and by the lubrication regime that prevents metal-to-metal contact. Real-world factors like misalignment and temperature further shape usable capacity.

The main determinants are contact stress limits and lubrication regime, with misalignment and temperature influencing real-world capacity.

Can lubrication failure lower capacity?

Yes. Poor lubrication increases friction, raises surface wear, and reduces the protective film, all of which lower the bearing’s effective carrying capacity.

Yes. Lubrication problems reduce film strength and increase wear, cutting capacity.

How do misalignment and preload affect capacity?

Misalignment creates uneven load distribution and hot spots, while incorrect preload can cause excessive friction or uneven support, both reducing capacity.

Misalignment and preload impact how evenly the load is shared; mistakes here reduce capacity.

Is capacity higher for newer designs?

Newer designs with better materials and lubrication can achieve higher practical capacity, but real-world outcomes depend on installation, maintenance, and operating conditions.

Newer designs can help, but real gains come from proper installation and maintenance.

What steps can engineers take to improve capacity?

Choose appropriate bearings, ensure correct fits, optimize lubrication, control temperature, and maintain alignment and cleanliness to sustain capacity.

Use the right bearing, keep it clean and well-lubricated, and maintain alignment to improve capacity.

Does temperature or speed significantly influence capacity?

Yes. Temperature affects lubricant viscosity and material properties; speed changes lubricating regimes and heat generation, both impacting capacity.

Temperature and speed change how well the bearing can carry load; they influence lubrication and heat.

Top Takeaways

- Assess bearing selection against the actual load profile

- Prioritize lubrication quality and film integrity

- Control misalignment and set correct preload

- Apply design margins and safety factors

- Plan proactive maintenance to sustain capacity