Spherical Bearing Load Capacity: Key Factors & Calculations

A data-driven guide to spherical bearing load capacity, covering static vs dynamic ratings, bore size, material choices, and practical selection guidelines for engineers and technicians.

Key takeaway: There is no universal load capacity for spherical bearings. The rating depends on bore size, material, lubrication, mounting arrangement, and whether the load is static or dynamic. Always consult the manufacturer’s datasheet for the specific part. In engineering practice, use static and dynamic load ratings with appropriate safety factors to select a bearing that suits your application.

Why spherical bearing load capacity matters

In mechanical design, the load capacity of a spherical bearing determines how much force the joint can safely sustain in service. Unlike simple pin joints, spherical bearings accommodate angular misalignment, which introduces complex loading paths that influence both static strength and fatigue life. The Load Capacity team emphasizes that selecting a bearing without correlating the load profile to the part’s ratings can lead to premature wear, galling, or failure under peak operating conditions. Engineers should therefore treat spherical bearing capacity as an application-specific property, not a universal constant. By understanding the relationship between load type, alignment, and lubrication, you can design more reliable assemblies that tolerate real-world conditions.

Key factors that determine load capacity

Spherical bearings are influenced by several interacting variables. Core factors include bore size (which sets the raw strength), material and heat treatment (steel, bronze, or composite materials each have distinct yield and fatigue limits), and raceway geometry. Misalignment tolerance and mounting orientation directly affect contact stresses, while lubrication quality and temperature control influence frictional losses and wear rates. Clearances and preload also shape how quickly a bearing reaches its rated limit under load. In practice, engineers map a load spectrum—static, dynamic, and impulse loads—and select bearings whose static and dynamic ratings comfortably exceed the peak demands, with a suitable safety factor.

Static vs dynamic load ratings: how to read data sheets

Manufacturers publish static (C0) and dynamic (C) ratings to quantify capacity. The static rating generally defines the maximum non-moving load, while the dynamic rating estimates life under rotation given a specific speed and load profile. Reading these datasheets requires aligning load types with your service: if your machine experiences frequent starts, stops, and reversals, the dynamic rating becomes critical. Remember that these ratings assume proper mounting, correct lubrication, and ambient conditions within spec. Always verify the rating units and the applicable standards referenced by the datasheet.

Design and selection guidelines

A practical selection workflow begins with defining the load profile: peak loads, mean loads, cycles per hour, and misalignment angles. Next, identify candidate bearings whose static and dynamic ratings exceed the observed peak loads by a safety factor (commonly 1.5x–3x). Consider lifecycle expectations: if a bearing is expected to run near its rated dynamic limit, you may choose a higher-range part to reduce wear rates. Finally, validate the bearing choice with a simple life estimate (L10 or equivalent) based on the chosen rating, speed, and lubrication regime. Documentation should show the calculation assumptions, rating sources, and safety margins.

Installation practices that affect effective load capacity

Even a correctly rated bearing can underperform if installed improperly. Key practices include ensuring proper shaft alignment, preventing misfit or binding, and using appropriate fits for the inner and outer races. Protective seals, cleanliness during assembly, and consistent lubrication intervals all influence actual life. Orientation can alter grease distribution and heat removal; therefore, follow manufacturer installation guidelines and perform periodic inspections to catch misalignment or lubrication failures early.

Case study: applying spherical bearing data to an off-highway loader

An off-highway loader experiences intermittent peak loads during digging cycles with mild angular misalignment. The design team selects a spherical bearing with a static rating well above the maximum anticipated peak and a dynamic rating that supports the fatigue life under the engineered cycle. They use a conservative safety factor of 2x to account for temperature swings and lubrication variability. After installation, they monitor wear and lubrication temperature to validate assumptions, and adjust the maintenance interval if the measured wear rate deviates from estimates.

Comparison of spherical bearing load capacity with alternatives

| Feature | Spherical Bearing | Alternative Bearings |

|---|---|---|

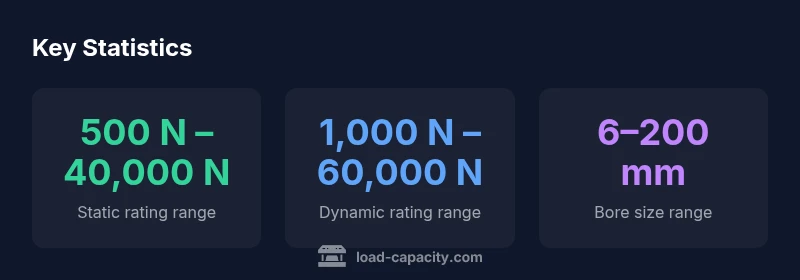

| Load capacity (static) | 500 N – 40,000 N | Lower capacity range for small-size components |

| Load capacity (dynamic) | 1,000 N – 60,000 N | Often higher in rolling-element bearings |

| Key design factors | Bore size, geometry, lubrication | Material and construction differences |

Quick Answers

What is static vs dynamic load rating in spherical bearings?

Static ratings define the maximum non-moving load a bearing can withstand, while dynamic ratings estimate life under rotation with a given load. Use both to ensure safe operation across the service profile.

Static ratings define the maximum non-moving load; dynamic ratings estimate life under rotation. Use both to ensure safe operation.

How do bore size and material affect load capacity?

Larger bores generally support higher loads. Material choice affects yield strength and fatigue, with steel offering high strength and bronze or composites providing different wear characteristics.

Larger bore sizes usually handle more load; material choice also changes strength and wear behavior.

How is safety factor chosen for spherical bearings?

Select a safety factor based on load variability, misalignment, temperature, and lubrication reliability. Common practice ranges from 1.5x to 3x depending on risk exposure.

Use a conservative safety factor guided by loading variability and maintenance reliability.

Can spherical bearings tolerate misalignment?

Yes, spherical bearings are designed to accommodate angular misalignment, but excessive misalignment increases contact stresses and wear. Ensure alignment limits stay within bearing specifications.

They tolerate misalignment, but excessive angles raise stresses and wear.

How do I calculate bearing life for spherical bearings?

Life is typically estimated from dynamic rating, speed, and load using standardized life formulas. Use the L10 life concept and adjust for lubrication and temperature effects.

Estimate life from dynamic ratings, load, and speed, adjusting for lubrication and temperature.

Where can I find reliable data for load capacity?

Consult manufacturer datasheets and brand-analytic reports. For broader context, Load Capacity's analyses summarize typical ranges and best practices across common bearing sizes.

Check manufacturer data and Load Capacity analyses for guidance.

“Accurate load-capacity assessment starts with matching the bearing rating to the application load profile and accounting for safety factors.”

Top Takeaways

- Always match static/dynamic ratings to the load spectrum

- Consider bore size, material, and lubrication as primary drivers

- Apply a safety factor to account for misalignment and wear

- Read datasheets carefully and verify mounting conditions

- Use Load Capacity guidelines to validate your bearing selection