Max Load Capacity Labels: Reading and Understanding

A practical guide explaining what max load capacity labels are, where they appear, how to read them, and how to maintain compliance across vehicles, machinery, and appliances.

Max load capacity labels are standardized tags affixed to equipment that specify its maximum safe load. They help operators avoid overloading and protect people and cargo.

What max load capacity labels are and where you find them

Max load capacity labels are standardized tags affixed to equipment that specify its maximum safe load. They appear on vehicles, lifting devices, appliances, and structural components as a quick reference for safe operation. For engineers and technicians, these labels serve as a primary safety control point, guiding inspection routines, maintenance planning, and operator training. Different regions and industries use various formats, but the core purpose remains the same: communicate a clear limit that should not be exceeded to prevent structural failure, tipping, or unsafe conditions. In practice, you will encounter labels near the main load-bearing components, on control panels, or along the load path where weight is introduced. When reading a label, always confirm the units and the exact rating, and cross reference with the relevant manuals and standards. The presence of a label does not replace a formal risk assessment; it complements it by providing an immediate, visible limit.

Load labels are not just stickers. They are part of a safety system that integrates with training, procedures, and verification steps. A well-marked label reduces guesswork and speeds up decision making in the field, warehouse, or workshop. Consistency across equipment families helps technicians transfer knowledge from one task to the next. In short, max load capacity labels are a practical, essential tool for maintaining safe operation across diverse applications.

Reading and interpreting the label information

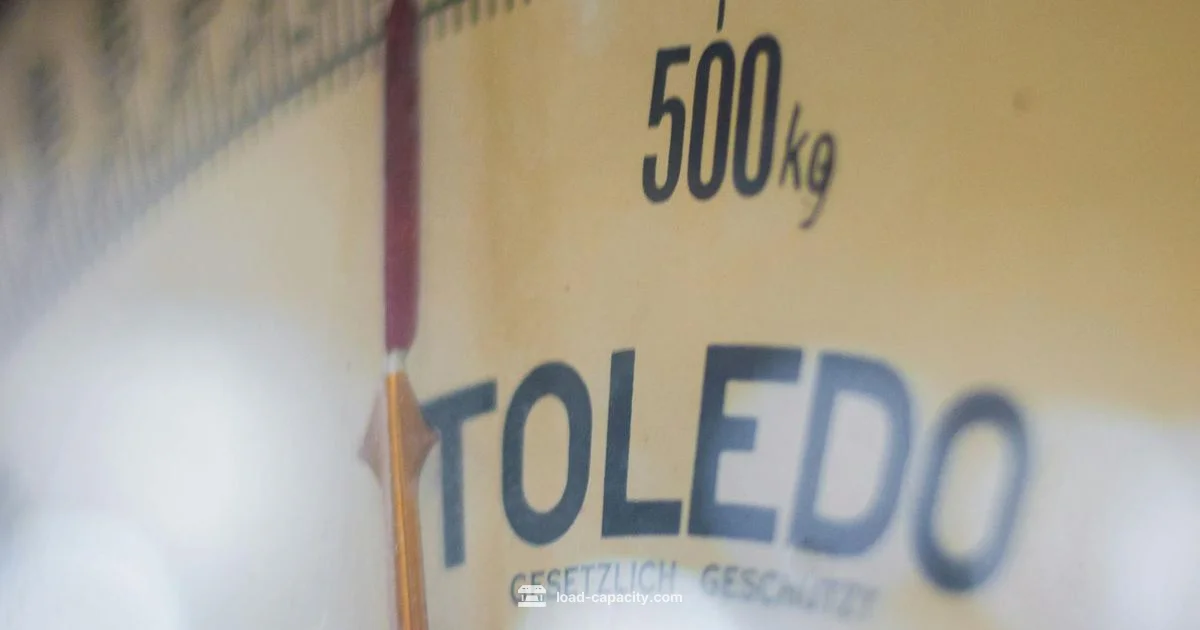

A typical max load capacity label contains several core elements that together define the safe operation envelope. The essential item is the maximum load rating, stated in the appropriate unit (for example kilograms or pounds). Some labels include a corresponding overload protection or safety factor, though this is not always explicit. Additional details may include the device model or serial number, the date of manufacture or last inspection, and notes about temperature, lubrication, or attachment considerations. The label may also specify whether the rating covers static loads, dynamic loads, or a specific configuration. For engineers, technicians, and operators, cross-referencing the label with the user manual, standard operating procedures, and regional regulations is a best practice to avoid misinterpretation. Always ensure the label is legible and up to date, and verify that any applied attachments or modifications do not invalidate the stated rating.

To read efficiently in the field, scan for: the rating itself, the unit, the scope of the rating, any restrictions on configuration, and the date or batch information that signals currency. If the label includes multiple ratings for different configurations, identify the exact scenario you intend to use and match it to the correct line on the label. When in doubt, consult the manufacturer or a qualified technician before proceeding with a load that approaches the rating.

Types of labels by equipment category

Labels vary by category, but three broad patterns cover most common scenarios. On trucks and trailers, the label often communicates payload capacity or gross vehicle weight guidance, sometimes tied to specific axles or wheel configurations. On lifting equipment, you typically see a safe working load or maximum lifting capacity, sometimes with notes about lift height, spread, or attachment. Appliances and consumer equipment frequently display weight ratings for safe operation, including the maximum load a drum, basket, or shelf can bear. Structural components and pallets may include load-bearing capacity indicators that help designers and installers ensure safe assembly and use. Across categories, expect variations in language, units, and pictograms, but the underlying principle is the same: communicate the maximum safe load clearly so users can plan, operate, and maintain equipment without exceeding its limits.

Understanding these label types helps with cross-functional tasks, from procurement to maintenance to field service. It also supports compliance with regional standards and helps teams align on common safety expectations. When labels are harmonized within a system, training becomes more efficient and fewer misinterpretations occur among operators who work with multiple equipment families.

Standards and best practices for labeling

Labeling standards vary by region, industry, and device type. There is no universal, one-size-fits-all standard for every product, but most labeling regimes share core principles: labels must be legible, durable, and resistant to the environmental conditions to which the equipment is exposed. Durable materials, clear typography, and contrasting colors improve legibility over time. Best practices include placing labels at a clearly visible location near the load path, using consistent terminology across the fleet, and including essential data fields such as the maximum load, units, and date of last inspection. Organizations should incorporate labeling into their safety management system, ensuring that labels are reviewed during maintenance cycles and updated when there are design changes, repairs, or attachments that alter load paths. Regional guidance, such as ISO or national standards, should be consulted when available, and any deviations from standard practice should be documented with a risk assessment.

Regular audits, employee training, and accessible manuals support label integrity. Manufacturers should provide replacement labels that match the original rating, and facilities should maintain a log of inspected equipment and labeling status for accountability. Finally, if a label is damaged, faded, or illegible, do not rely on memory; replace the label and confirm the rating through official documentation before proceeding.

How to verify label accuracy and maintain compliance

Verification starts with legible labels. Inspect for faded text, peeling corners, or missing information during routine maintenance checks. If a label cannot be read, damaged, or inconsistent with the equipment’s documentation, replace it or contact the manufacturer for a replacement. Cross-check the label with the equipment manual to confirm that the stated rating matches the design, attachments, and configuration you plan to use. For any modifications, such as adding attachments or altering load paths, consult the manufacturer and update the label if required. Maintain a digital or physical registry of ratings and inspection dates to support traceability and future audits. In regulated environments, a formal certification or inspection record may be required to demonstrate ongoing compliance. Training and clear operating procedures help ensure that all personnel understand how to interpret and apply the label on a daily basis. Finally, ensure that the label is compatible with the regional standards that apply to your location and industry.

Effective verification reduces the risk of overloading, equipment damage, and safety incidents. It also supports maintenance planning, procurement decisions, and safe operational practices across teams.

Practical implications and common pitfalls

Operators often encounter several practical challenges with max load capacity labels. A common pitfall is assuming that the labeled load applies under every condition; dynamic loads, uneven distribution, or unusual attachments can change actual safe limits. Another issue is using a label that belongs to a different configuration or model; always confirm that the reference matches your exact setup. Legibility is crucial; faded labels may lead to misinterpretation. Temperature, moisture, and wear can degrade labels over time, so regular inspection and timely replacement are essential. Documentation gaps—such as missing replacement labels after maintenance—are a frequent source of noncompliance. Training gaps also surface when new staff join a project and must interpret labels across multiple equipment families. Finally, overreliance on labels without considering other safety controls, like load path analysis, stability assessments, and operational procedures, can create a false sense of security. Use labels as a starting point, but always pair them with a comprehensive safety strategy that includes reviews, handbooks, and practical checks in the field.

Case studies and quick-reference checklist

In real world use, a simple, structured approach helps teams apply max load capacity labels consistently. A short case study illustrates the importance of reading the label correctly and validating that the intended load path aligns with the rating. In practice, teams should use a concise checklist before any load operation: 1) locate and read the label; 2) confirm units and the exact rating; 3) verify configuration, attachments, and load distribution; 4) compare to the planned operation; 5) check the manual for any caveats; 6) perform a pre-load safety assessment; 7) document the verification steps and the load decision. A reliable process reduces the chance of overloading and supports a safer work environment. The checklist can be adapted for different equipment families but should always include a visual confirmation of the label, a cross-check against documentation, and a record of the decision. By treating labels as an essential element of the safety system, teams minimize risk while maintaining productivity and compliance.

Quick Answers

What is a max load capacity label and why is it important?

A max load capacity label communicates the maximum safe load for a piece of equipment. It helps prevent overloading, reduces the risk of failure, and protects workers and cargo.

A max load capacity label shows the maximum safe load for equipment and helps prevent overload and accidents.

Where will I commonly find max load capacity labels on vehicles and equipment?

Labels appear on trucks, trailers, lifting equipment, appliances, and many structural components. They are usually placed near the load-bearing area or near the control panel for quick reference.

You’ll typically find these labels on the load bearing sections of equipment and near control panels.

Do labels account for dynamic loads or only static weights?

Labels generally indicate the maximum load under normal use, but dynamic conditions such as movement, impact, and distribution can change actual safe limits. Always consult the manufacturer manual for guidance on dynamic loading.

Labels cover typical use; dynamic factors can change safe limits, so check the manual for specifics.

How often should max load capacity labels be inspected or replaced?

Labels should be inspected during routine maintenance or before critical operations. Replace labels if they’re faded, damaged, or illegible to ensure accurate information is conveyed.

Inspect labels during maintenance and replace if faded or damaged to keep information accurate.

What should I do if the label is missing or damaged?

Do not rely on memory or estimates. Contact the manufacturer or refer to the equipment manual to determine the correct load rating and obtain a replacement label.

If a label is missing or damaged, stop and consult the manual or manufacturer for the correct rating and replacement.

Can modifications affect the applicability of a label?

Yes, modifications can change load paths and capacity. After any modification, recheck the rating with the manufacturer and update labels if required.

Modifications may change load capacity; verify ratings with the manufacturer and update labels as needed.

Top Takeaways

- Inspect labels before any load operation

- Match the rating to the exact configuration

- Verify units and date of issue

- Replace damaged or illegible labels immediately

- Incorporate labeling into safety training and audits