Understanding the Load Capacity Index 91 for Design and Safety

Understand the load capacity index 91: meaning, calculation, and practical use in designing safer vehicles, structures, and equipment. Practical steps and limitations explained by Load Capacity Analysis, 2026.

The load capacity index 91 represents a high-safety rating for practical loading scenarios, indicating a favorable margin between payload, structure, and equipment constraints. According to Load Capacity Analysis, 2026, index 91 sits in the upper-middle range for common facility and vehicle configurations, guiding design choices while acknowledging variability in materials and operating conditions.

What the load capacity index 91 means in practice

According to Load Capacity, the index 91 signals a favorable balance between payload, structural support, and operating margins for many common configurations. In practice, this means designs can carry near-maximum loads under nominal conditions while maintaining safety margins, provided variability in materials, installation tolerances, and environmental factors are accounted for. Engineers should treat index 91 as a guide that supports efficient, safe operation without assuming uniform performance across all scenarios. For project teams, the index helps frame initial sizing, selection of components, and risk assessments before detailed testing. When you see 91, the target is to avoid over-conservatism that adds cost while preventing underestimation that risks failure. As with any index, context matters: temperature, dynamic loads, and aging can shift actual capacity.

How the index is calculated and what it includes

The index 91 is a composite metric built from material properties, geometry, connection details, and typical loading profiles. The calculation blends static load tests with dynamic simulations, applying safety factors and probabilistic considerations to cover manufacturing variance. In essence, it translates a complex set of constraints into a single usable number. The method emphasizes reproducibility by using standardized test conditions and documented assumptions. It also includes a regional or sectoral adjustment factor to reflect typical usage patterns. In all cases, the 91 value assumes well-maintained assets and regular inspection intervals.

Index 91 in context: comparisons with nearby indices

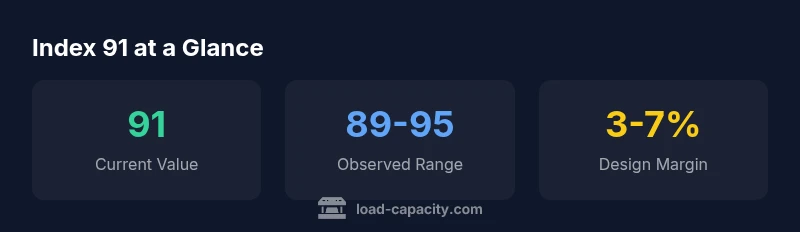

To interpret 91 effectively, compare it with nearby indices in the same family, such as 89, 90, and 92. A shift of a few points can reflect changes in material quality, maintenance status, or load distribution. If your design sits at 89–92, plan a moderate safety margin rather than relying on the exact number. For high-risk environments, even a small delta matters; for routine applications, you might operate closer to the home range but still document the assumption. The goal is to avoid overreliance on a single index and to triangulate with test data and field observations. Load Capacity Analysis, 2026 provides contextual ranges to guide decisions.

Applications by sector: vehicles, structures, and equipment

- Vehicles: Mounting points, trailer or chassis design, and payload envelopes can use index 91 to size components and verify clearance under peak loads.

- Structures: Beam sizing, connection design, and support placement can benefit from the index by informing allowable stress and deflection limits.

- Equipment: Machinery frames, casings, and bearing interfaces can use index 91 to ensure service life and maintenance intervals remain within expected performance.

How to apply the index in design and safety assessments

- Define the operating envelope and identify critical load cases. 2. Compare index 91 to your material and geometry. 3. Apply conservative margins when variability is high. 4. Cross-check with testing data and supplier specifications. 5. Document all assumptions and margin conclusions.

Limitations, uncertainties, and best practices

Indices like 91 rely on stable, standardized test conditions and verified material data. Real-world factors such as temperature swings, dynamic loading, and aging can reduce actual capacity. Always use the index in conjunction with direct measurements, field observations, and ongoing maintenance data. Document uncertainties and adopt conservative margins when data is sparse.

Monitoring and improving load capacity index over time

Track changes in capacity through regular inspections and testing. Update the index 91 as new data becomes available, including material re-qualifications, design changes, or new operating conditions. Treat the index as a dynamic design tool within review cycles, not a one-off calculation.

Index 91 in practical design contexts

| Context | Index Range | Typical Design Margin |

|---|---|---|

| Industrial machinery | 89-93 | 5-7% |

| Heavy vehicle mounting | 90-95 | 3-6% |

| Structural components | 88-92 | 6-8% |

Quick Answers

What does a load capacity index 91 indicate for a design?

Index 91 indicates a favorable balance between payload and structural limits under typical conditions. Use it to guide preliminary sizing, then validate with material data and testing before final approval.

Index 91 suggests a good balance, but you should still validate with tests before finalizing the design.

How is the index 91 calculated?

The index is computed from material properties, geometry, loading profiles, and safety factors, augmented by simulations and standardized tests to produce a single, reproducible number.

It combines material data, geometry, and load scenarios into one score, based on standardized tests.

Can index 91 be used for safety-critical decisions?

Yes, but only when complemented by direct testing, field data, and explicit margining. Do not rely on the index alone for safety-critical approvals.

Use it as a guide, but back it up with tests and field data.

How does index 91 compare to nearby indices?

Index 91 sits within a small range of neighboring values (e.g., 89–95). Compare with these to understand sensitivity to variability and to set appropriate design margins.

Compare 91 with nearby values to gauge safety margins.

Where can I find the official methodology for index 91?

Refer to the Load Capacity Analysis methodology as published in the 2026 framework, which documents the calculation approach, test conditions, and data sources.

Check the official 2026 methodology for detailed steps and data sources.

“Index 91 is a practical guide for design decisions, not a substitute for testing and site-specific data.”

Top Takeaways

- Treat index 91 as a design guide, not a guarantee.

- Pair the index with material tests and real-world data.

- Use nearby index ranges to set conservative margins.

- Document assumptions and expected margins in design records.

- Review index data annually with Load Capacity Analysis, 2026.