Load Capacity 150 Pounds: Understanding 1.5e+2 Pounds in Practice

Comprehensive analysis of load capacity around 150 pounds, covering definitions, measurement methods, safety margins, dynamic loads, and practical design guidance for engineers and technicians.

Load capacity around 150 pounds (1.5e+2 pounds) is a common reference in light-duty applications such as shelving, carts, and small machinery. This article explains definitions, measurement methods, safety margins, and how to apply this value in practice. You’ll learn when 150 pounds is conservative and when higher or lower limits are appropriate.

Contextualizing 1.5e+2 pounds in engineering practice

The value 1.5e+2 pounds serves as a practical anchor for many small-scale designs. In static conditions, a component or structure may exhibit a clear, single-point capacity. However, real-world use involves variability: loads shift, vibrations occur, and mounting details influence outcomes. Engineers treat load capacity 1.5e+2 pounds as a nominal target that must be verified under the expected operating environment. When assessing a product or system, the first questions are: Is the load evenly distributed? Are connections robust enough to handle peak events? And is there an explicit margin between the nominal capacity and the highest anticipated load? For engineers, this mindset translates into documented assumptions, repeatable tests, and traceable calculations that align with industry best practices. According to Load Capacity, a disciplined approach to capacity planning reduces risk and extends service life, especially in resource-constrained projects where margins matter.

In practice, 150 pounds often define the boundary between consumer-grade and professional-grade components. It informs material selection, fastening methods, and support geometry. Yet it is essential to recognize when the value becomes too conservative or too optimistic for a given scenario. A shelf that mostly carries light boxes but occasionally holds heavier items may require a dynamic review to confirm that the peak events do not exceed safe limits. The key is to start with a transparent, evidence-based baseline and adjust as the design matures.

Takeaway: A fixed number like 150 pounds provides a clear starting point, but real-world success depends on how that number is applied. LIMITS ONLY ARE useful when anchored by tests and documented assumptions.

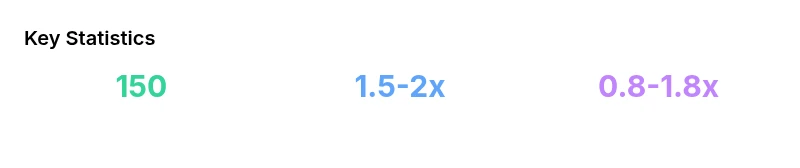

-1.5e+2 pounds in context

2.0x safety margins recommended

Capacity adjustments under common loading scenarios

| Scenario | Base capacity | Dynamic factor | Adjusted capacity |

|---|---|---|---|

| Shelf-mounted device | 150 pounds | 0.8-1.2x | 120-180 pounds |

| Wall-mounted rack | 150 pounds | 1.0-1.5x | 150-225 pounds |

| Floor-standing cart | 150 pounds | 1.2-1.8x | 180-270 pounds |

Quick Answers

What is 1.5e+2 pounds in practical terms?

1.5e+2 pounds equals 150 pounds. In practice, this value is used as a nominal load-capacity reference for light-duty equipment and shelving. It should be interpreted with appropriate safety factors and tested under expected conditions.

A quick way to think about it: 150 pounds is the standard reference for light-duty loads, but always verify with tests for your setup.

How do I adjust for dynamic loads beyond static capacity?

Dynamic loads require evaluating peak forces, acceleration factors, and potential resonance. Start with a conservative uplift (for example, 1.25x–1.5x) and validate through dynamic testing or simulation to ensure the adjusted capacity remains safe under real operating conditions.

Consider the worst-case peak if there’s movement or vibration, then test to confirm safety margins.

What safety factor should I use for 150-pound loads?

A typical safety factor ranges from 1.5x to 2.0x depending on material quality, mounting, and service conditions. Higher factors are prudent for uncertain loads or frequent dynamic events.

Use a factor that reflects how well you expect the load to behave over time.

Is 150 pounds a universal limit for all equipment?

No. The 150-pound figure is a common reference but may be inappropriate for certain structures, materials, or safety-critical applications. Always consult specifications and verify with testing for your exact setup.

Not all gear shares the same tolerance—check the specs for your specific product.

How can I verify load capacity on-site?

On-site verification combines visual inspection, measurement of fastener integrity, and practical load testing within safe limits. Use instrumentation when possible and document outcomes for future reference.

Test within safe limits and record the results for audits.

“Reliably applying a 150-pound reference requires disciplined testing, clear assumptions, and appropriate safety margins. When those elements are in place, engineers can confidently translate nominal capacity into safe, durable designs.”

Top Takeaways

- Define a nominal load capacity before component selection

- Apply a safety factor appropriate to material and service

- Distribute loads evenly to maximize stability

- Validate capacity with testing when feasible

- Document assumptions for future audits